Main-grid-free high-efficiency back contact solar battery module, assembly and preparing process

A solar cell, high-efficiency technology, applied in the field of solar cells, can solve the problems of complex conductive backplane manufacturing process, affecting the overall performance of battery components, low production efficiency, etc., reducing electron collection distance, eliminating shading loss, and manufacturing costs. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

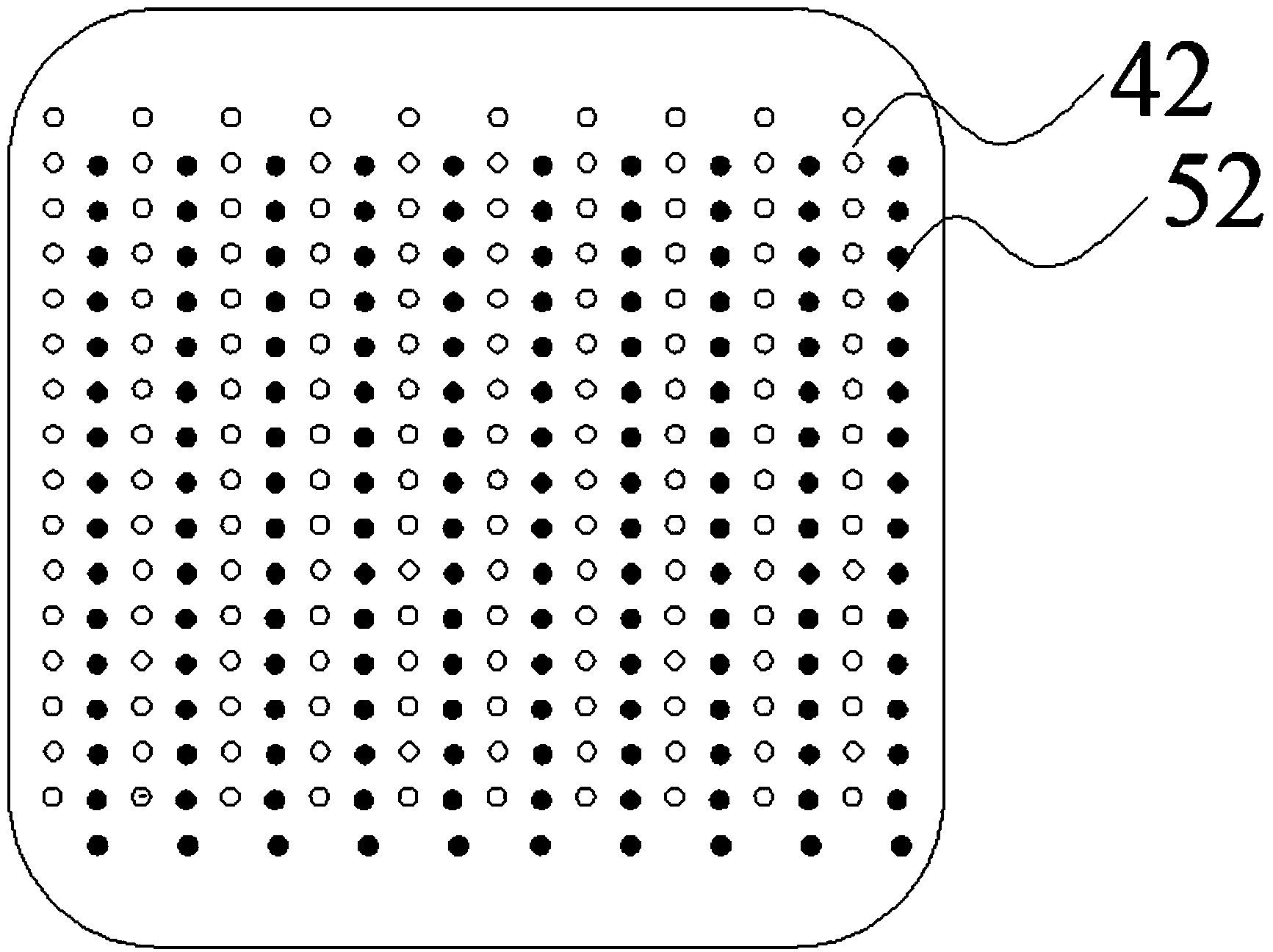

[0077] see figure 1 , image 3 , Figure 4 , Figure 5 , a busbar-free, high-efficiency back-contact solar cell module provided in this embodiment, the solar cell module includes a battery sheet and an electrical connection layer 12, the backlight surface of the battery sheet has a P-type doped layer connected The P electrode and the N electrode connected to the N-type doped layer. The insulating layer between the P electrode and the N electrode is provided with a thermoplastic resin or a thermosetting resin, and the resin is ethylene-vinyl acetate copolymer, polyolefin resin, epoxy resin, polyurethane resin, acrylic resin, organic silicon Any of the resins, preferably ethylene-vinyl acetate copolymer in this embodiment, can prevent short circuits between electrodes.

[0078] see figure 1 , the battery sheet is N-type monocrystalline silicon substrate silicon, the P electrode is a dotted P electrode 52, the N electrode is a dotted N electrode 42, and the dotted P electrod...

Embodiment 2

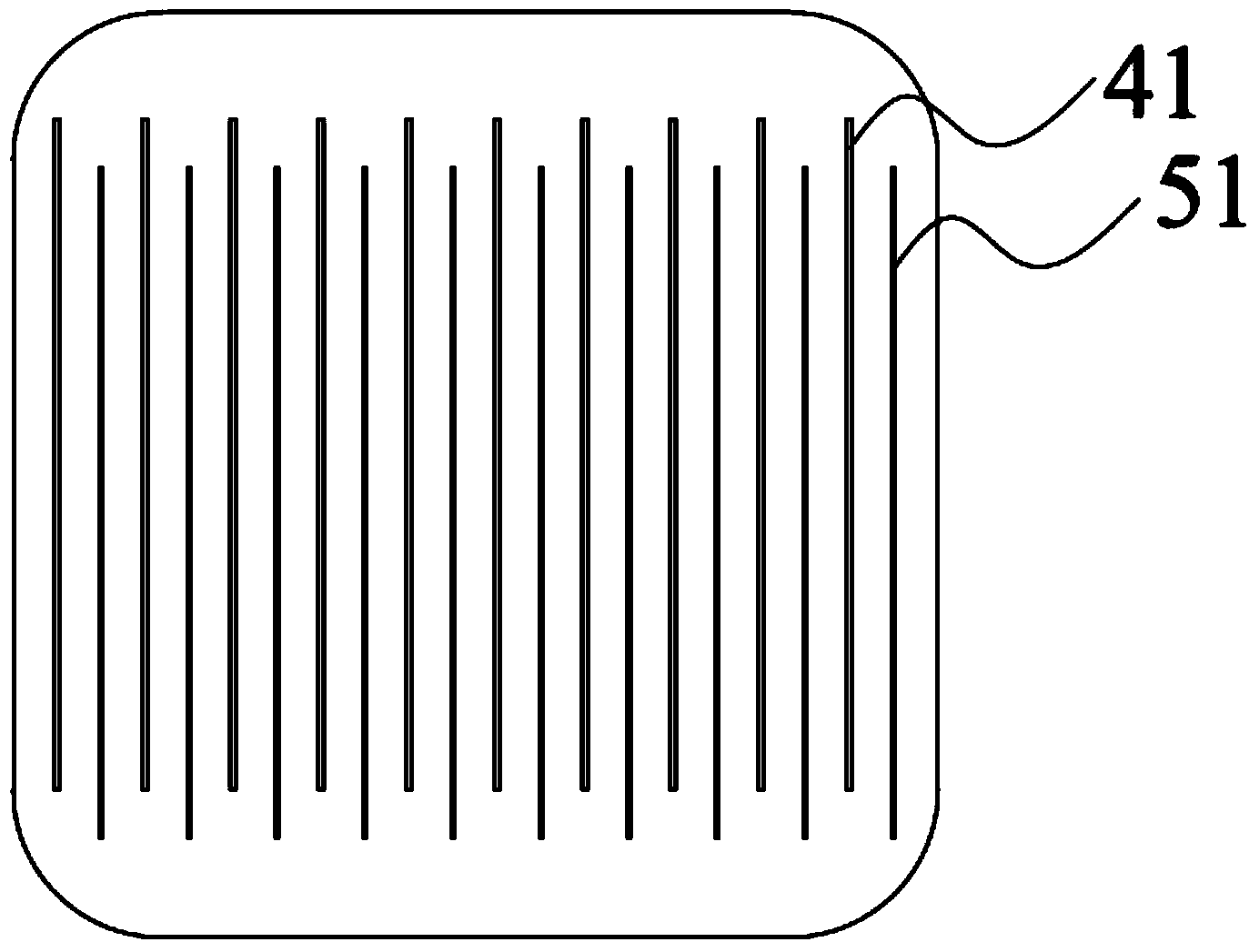

[0095] see figure 2 , image 3 , Figure 4 , Figure 5 , a busbar-free, high-efficiency back-contact solar cell module provided in this embodiment, the solar cell module includes a battery sheet and an electrical connection layer 12, the backlight surface of the battery sheet has a P-type doped layer connected The P electrode and the N electrode connected to the N-type doped layer. The insulating layer between the P electrode and the N electrode is provided with a thermoplastic resin or a thermosetting resin, and the resin is ethylene-vinyl acetate copolymer, polyolefin resin, epoxy resin, polyurethane resin, acrylic resin, organic silicon Any of the resins, preferably ethylene-vinyl acetate copolymer in this embodiment, can prevent short circuits between electrodes.

[0096] see figure 1, the cell is an N-type monocrystalline silicon substrate silicon, the P electrode is a linear P electrode 51, the N electrode is a linear N electrode 41, and the linear P electrode 51 a...

Embodiment 3

[0113] see figure 1 , image 3 , Figure 4 , Figure 5 , a busbar-free, high-efficiency back-contact solar cell module provided in this embodiment, the solar cell module includes a battery sheet and an electrical connection layer 12, the backlight surface of the battery sheet has a P-type doped layer connected The P electrode and the N electrode connected to the N-type doped layer. The insulating layer between the P electrode and the N electrode is provided with a thermoplastic resin or a thermosetting resin, and the resin is ethylene-vinyl acetate copolymer, polyolefin resin, epoxy resin, polyurethane resin, acrylic resin, organic silicon Any of the resins, preferably acrylic resin in this embodiment, can prevent short circuits between electrodes.

[0114] see figure 1 , the battery sheet is N-type monocrystalline silicon substrate silicon, the P electrode is a dotted P electrode 52, the N electrode is a dotted N electrode 42, and the dotted P electrode 52 and the dotted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com