Method for acquiring vitrification-silane compound modification layer on surface of steel body and modification liquid

A technology of compound modification and modification liquid, applied in the direction of metal material coating process, etc., can solve the problems of red tide, water pollution, photophobia, etc., and achieve the effect of avoiding eutrophication pollution and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0040] Step 1: Pretreatment, firstly polish the steel base, then perform ultrasonic alcohol cleaning, after cleaning, put it into the alkali washing liquid for degreasing treatment, the alkali washing adopts the water bath heating method, the temperature is 60 ℃, and the time is 10 minutes. Then rinse with deionized water and activate with pickling. Blow dry quickly.

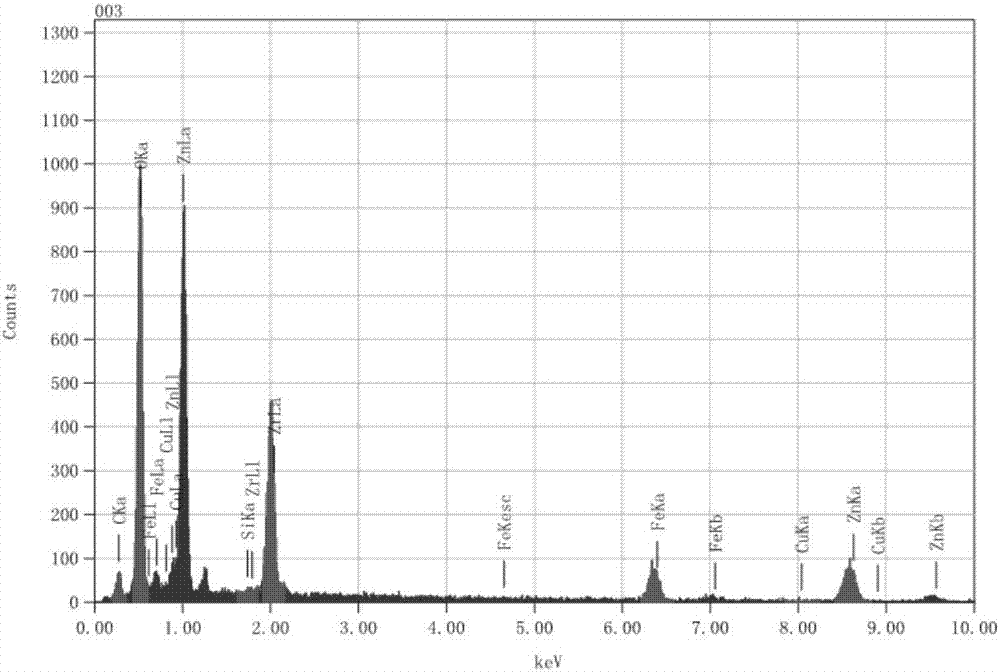

[0041] Step 2: Surface modification, the main components and contents of ceramic-silane composite modification liquid are 0.5g / L potassium fluorozirconate, 0.2g / L zinc sulfate, 0.1g / L manganese sulfate, 0.05g / L copper sulfate , 3ml / L OP-10, 80ml / L silane coupling agent pre-hydrolyzate, and adjust the pH of the compound modification solution to 3. The method is as follows: completely immerse the pretreated steel substrate in the vitrification-silane composite modification solution for 30 minutes, take it out, dry and solidify to obtain the vitrification-silane composite modification layer.

experiment example 2

[0043] Step 1: Pretreatment, firstly polish the steel base, then perform ultrasonic alcohol cleaning, after cleaning, put it into the alkali washing liquid for degreasing treatment, the alkali washing adopts the water bath heating method, the temperature is 60 ℃, and the time is 10 minutes. Then rinse with deionized water and activate with pickling. Blow dry quickly.

[0044] Step 2: Surface modification, the main components and contents of ceramic-silane composite modification solution are 2g / L potassium fluorozirconate, 1g / L zinc sulfate, 0.3g / L manganese sulfate, 0.07g / L copper sulfate, 5ml / L OP-10, 90ml / L silane coupling agent pre-hydrolyzed solution, the pH of the composite modified solution was adjusted to 2.5. The method is as follows: completely immerse the pretreated steel substrate in the vitrification-silane composite modification solution for 50 minutes, take it out, dry and solidify to obtain the vitrification-silane composite modification layer.

experiment example 3

[0046] Step 1: Pretreatment, firstly polish the steel base, then perform ultrasonic alcohol cleaning, after cleaning, put it into the alkali washing liquid for degreasing treatment, the alkali washing adopts the water bath heating method, the temperature is 60 ℃, and the time is 10 minutes. Then it was cleaned with deionized water and activated by pickling. Blow dry quickly.

[0047] Step 2: Surface modification, the main components and contents of ceramic-silane composite modification solution are 3g / L potassium fluorozirconate, 2g / L zinc sulfate, 0.4g / L manganese sulfate, 0.1g / L copper sulfate, 7ml / L OP-10, 100ml / L silane coupling agent pre-hydrolyzed solution, the pH of the composite modified solution was adjusted to 4. The method is as follows: completely immerse the pretreated steel substrate in the vitrification-silane composite modification solution for 50 minutes, take it out, dry and solidify to obtain the vitrification-silane composite modification layer.

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com