Nickel-cobalt hydroxide composite material, preparation method thereof and supercapacitor

A technology of nickel-cobalt hydroxide and composite materials, applied in the field of nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

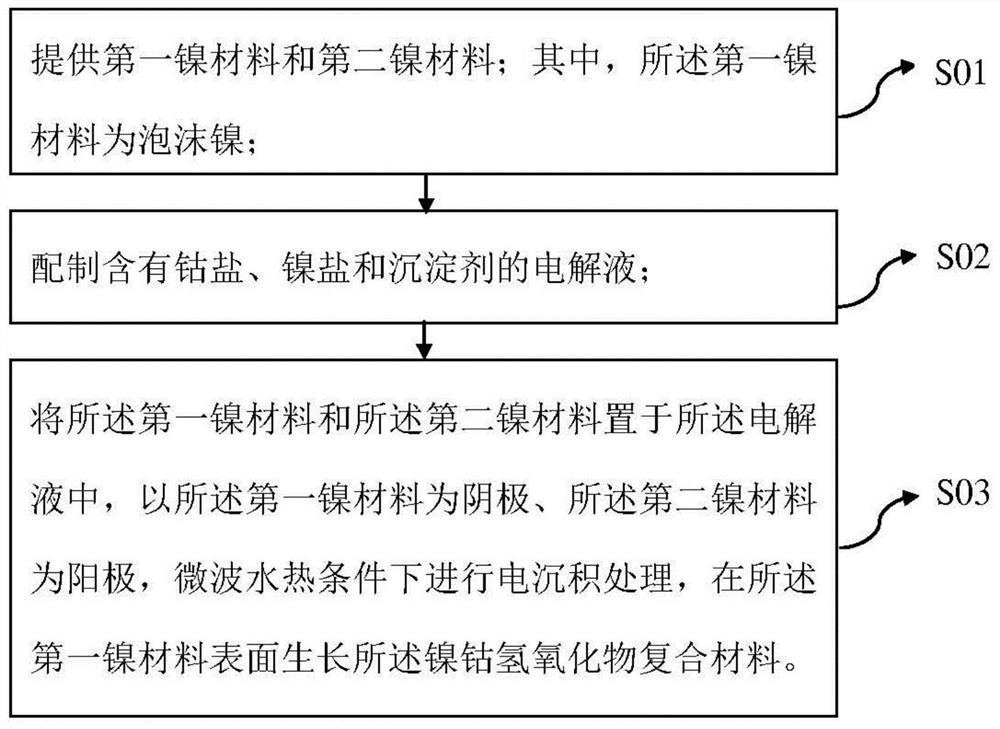

[0024] On the one hand, the embodiment of the present invention provides a kind of preparation method of nickel-cobalt hydroxide composite material, such as figure 1 Shown, this preparation method comprises the steps:

[0025] S01: providing a first nickel material and a second nickel material; wherein, the first nickel material is nickel foam;

[0026] S02: Prepare electrolyte solution containing cobalt salt, nickel salt and precipitant;

[0027] S03: Place the first nickel material and the second nickel material in the electrolyte, use the first nickel material as a cathode and the second nickel material as an anode, and conduct electrolysis under microwave hydrothermal conditions. Deposition treatment, growing the nickel-cobalt hydroxide composite material on the surface of the first nickel material.

[0028] The preparation method of the nickel-cobalt hydroxide composite material provided in the embodiment of the present invention is a method of in-situ generating a nick...

Embodiment 1

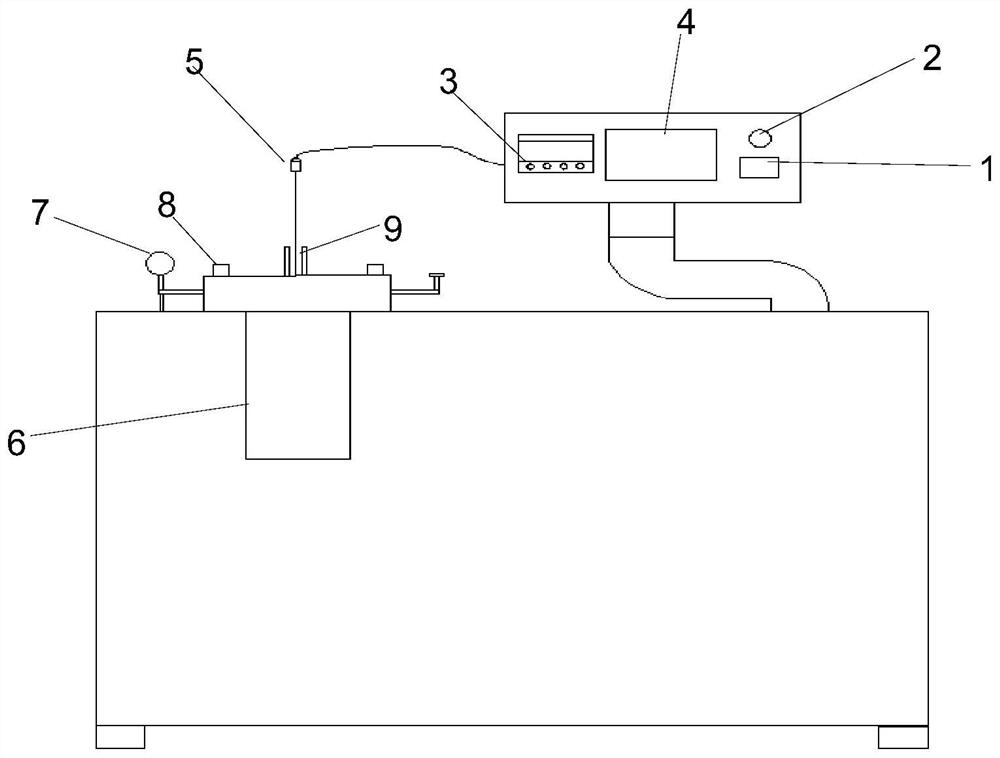

[0052] A device for preparing nickel-cobalt hydroxide composite materials, such as figure 2 As shown, the device includes: a microwave generator switch 1, a power regulator 2, a temperature regulator 3, a real-time display 4, a thermocouple 5, a reactor 6, a barometer 7, a nut 8, and a current terminal 9.

[0053] The device has five functions of microwave, hydrothermal, electrodeposition, and auxiliary circulating cooling and temperature control device. In the closed deposition space formed, the microwave generator generates microwave radiation and is installed in the reaction chamber (ie, the reaction kettle). The liquid-phase conductive medium acts on the liquid-phase conductive medium, and makes the liquid-phase conductive medium heat, and measures and monitors the reaction temperature in the sealed tank and the temperature of the tank wall through the temperature measuring element, and feeds back to the external switch control device to realize the effective self-control ...

Embodiment 2

[0055] A preparation method of nickel-cobalt hydroxide composite material, comprising the steps of:

[0056] Step S11: Provide nickel foam and nickel sheet: cut 10mm×10mm nickel foam, cut 10mm×10mm nickel sheet, and ultrasonically clean the nickel foam and nickel sheet with acetone, ethanol and deionized water for 5 minutes respectively;

[0057] Step S12: Preparation of electrolyte: 3 grams of cobalt nitrate hexahydrate, 1.05 grams of nickel chloride hexahydrate and 0.8 grams of urea were used as solutes, and 1 L of distilled water was used as a solvent. The four were mixed and stirred for 30 minutes to make 3 grams of cobalt nitrate hexahydrate and 1.05 1 g of nickel chloride hexahydrate and 0.8 g of urea were completely dissolved in 1 L of distilled water.

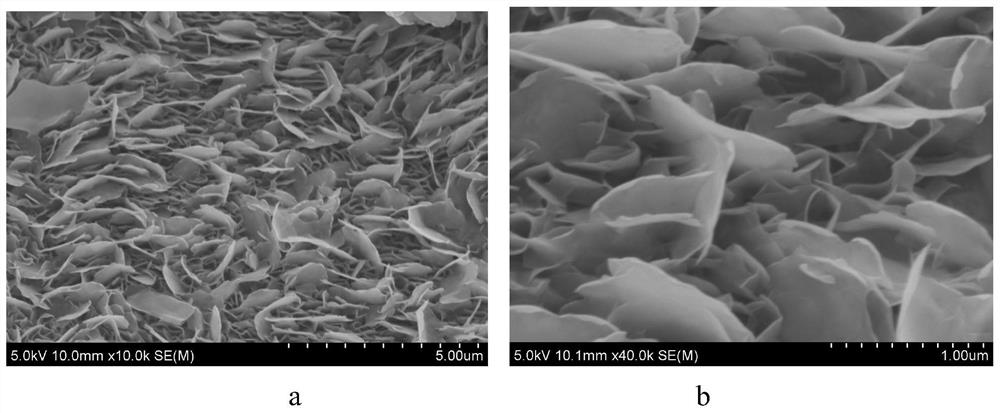

[0058] Step S13: Put the electrolyte solution prepared in step S12 into the chamber of the reactor of the microwave hydrothermal electrodeposition system. The 10mm×10mm nickel foam cleaned in step S11 is used as the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com