FeOOH/PVDF (Polyvinylidene Fluoride) fiber scaffold as well as preparation method and application thereof

A fiber scaffold and fiber membrane technology, applied in biochemical equipment and methods, fiber processing, filament/thread forming, etc., can solve the problem of weak influence of stem cell differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of FeOOH / PVDF fiber scaffold

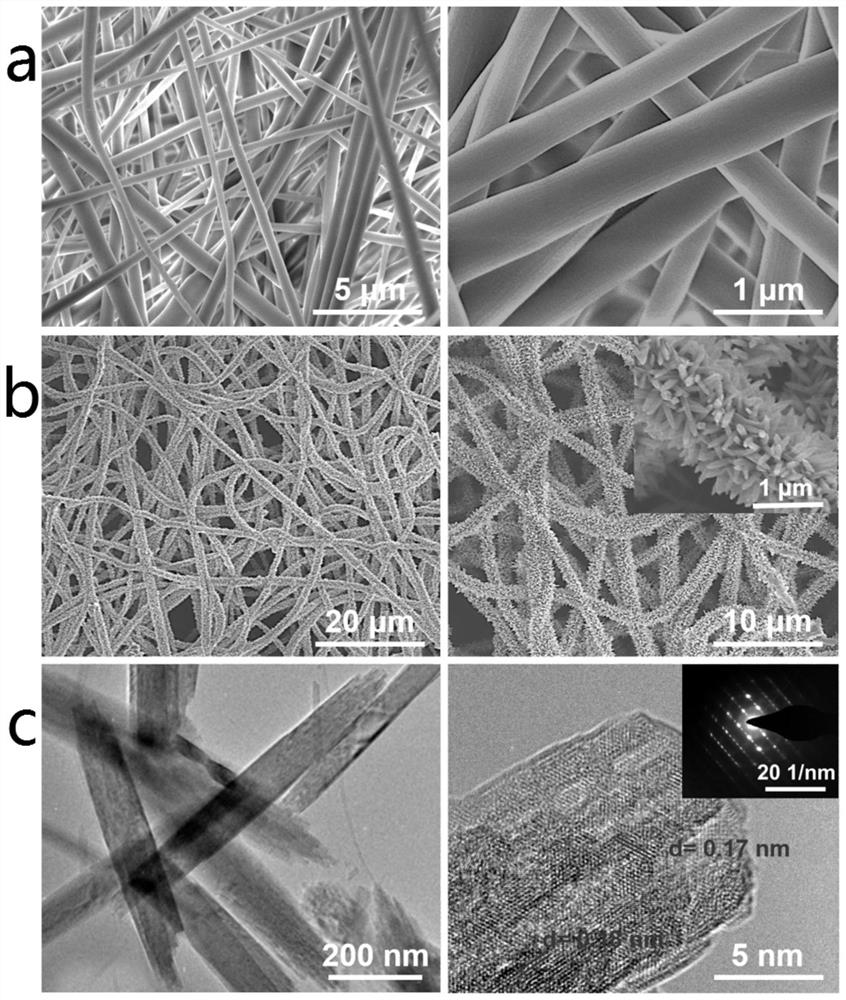

[0038] (1) Dissolve PVDF powder (Solvay 6010) in a mixed solvent of acetone: N,N-dimethylformamide = 3:7 (v / v), and configure a PVDF solution with a mass fraction of 12%; use a syringe to draw Insert about 5ml of PVDF solution into a 22G needle, and set the spinning parameters as follows: distance 15cm, voltage 18kV. After spinning, remove the membrane and dry it in an oven at 60°C for 30min to obtain a PVDF fiber membrane. The SEM Figure such as figure 1 As shown in a: the PVDF fiber surface is smooth and uniform in thickness, with a diameter of about 600nm;

[0039] (2) Weigh ferric chloride hexahydrate and sodium nitrate and dissolve them in 50 mL of distilled water so that the concentration of ferric chloride is 0.1 M and the concentration of sodium nitrate is 1 M. Add aqueous hydrochloric acid to adjust the pH to 1.25; add step (1) to prepare The good PVDF fiber membrane (size 2 cm×4 cm) was transferred to the ...

Embodiment 2

[0042] Example 2 Preparation of FeOOH / PVDF fiber scaffold

[0043] (1) The preparation of the PVDF membrane is the same as in Example 1 (1);

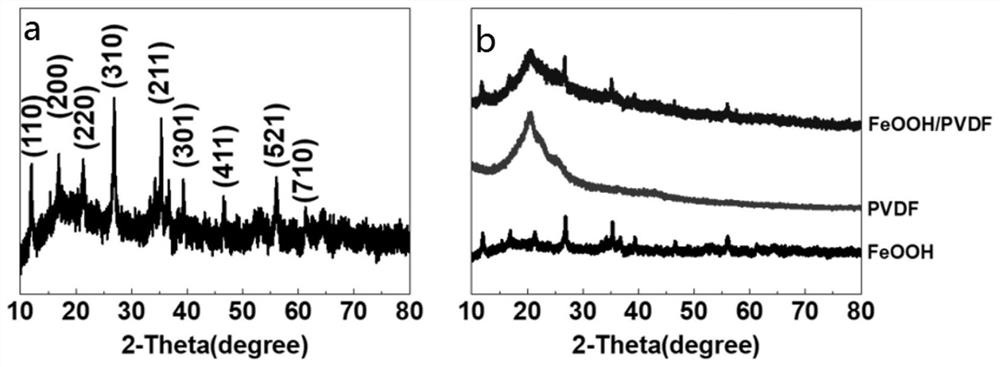

[0044] (2) Weigh ferric chloride hexahydrate and sodium nitrate and dissolve them in 50 mL of distilled water so that the concentration of ferric chloride is 0.12M and the concentration of sodium nitrate is 1M. Add aqueous hydrochloric acid to adjust the pH to 1.25; add step (1) to prepare The PVDF fiber membrane (about 2 cm × 4 cm) was transferred to the hydrothermal reaction kettle together, and then reacted at 95 ° C for 12 h, washed three times alternately with water and absolute ethanol, and dried to obtain the FeOOH / PVDF fiber scaffold. The TEM image of iron oxyhydroxide is shown in figure 1 As shown in a and b: FeOOH is rod-shaped, the crystal form is β-type, the size is uniform, the length is about 900nm, the width is about 100nm, and it has good crystallinity. SEM image of FeOOH / PVDF fiber scaffold Figure 5 As shown in c an...

Embodiment 3

[0045] Example 3 Preparation of FeOOH / PVDF fiber scaffold

[0046] (1) Dissolve PVDF powder (Solvay 6010) in a mixed solvent of acetone: N,N-dimethylformamide = 4:6 (v / v), and configure a PVDF solution with a mass fraction of 15%; use a syringe to draw Insert about 5ml of PVDF solution into a 22G needle, set the spinning parameters as follows: distance 15cm, voltage 20kV, after spinning, remove the membrane and dry it in a 60°C oven for 30min to obtain a PVDF fiber membrane, its SEM Figure such as Figure 8 shown. It can be seen from the figure that the PVDF fiber surface is smooth and uniform in thickness, with a diameter of about 600nm;

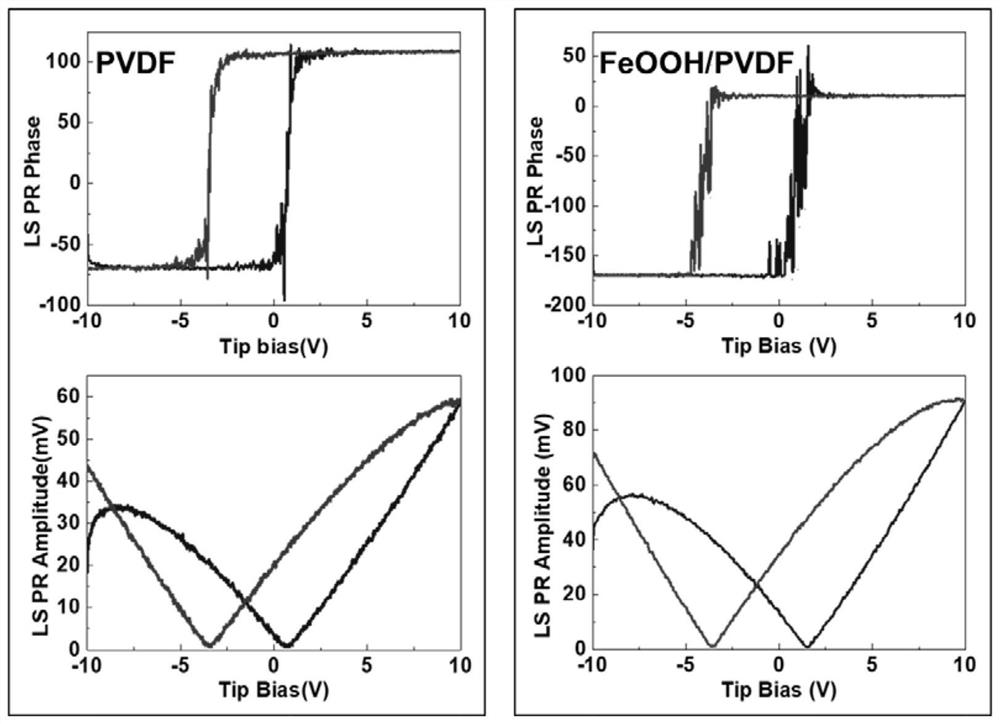

[0047] (2) The synthesis of FeOOH is the same as in Example 1 (2). PVDF membrane and FeOOH / PVDF membrane are carried out PFM test in step 1, the result is as follows Figure 9 It is shown that FeOOH / PVDF has good piezoelectricity, and at the same time, compared with PVDF, the piezoelectricity does not weaken significantly after loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com