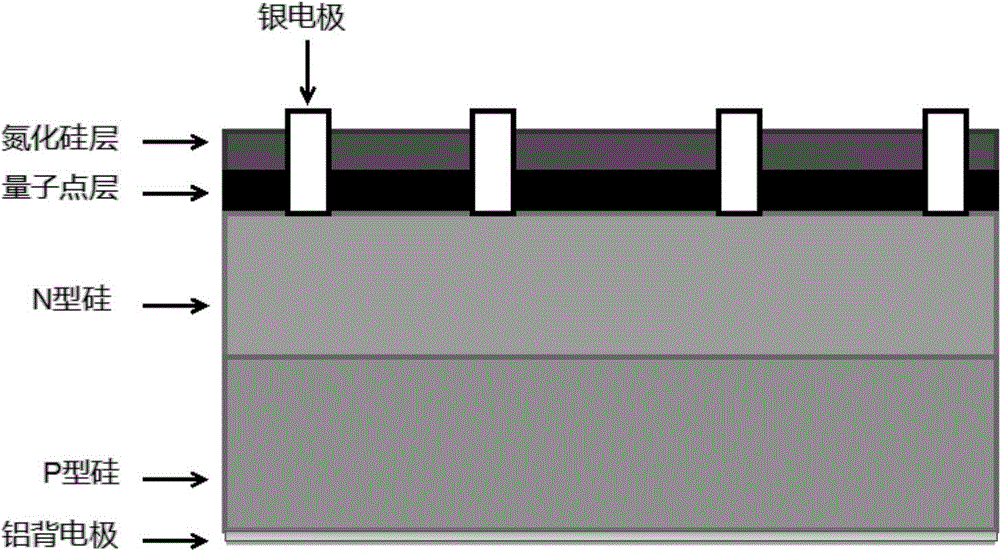

Preparation method of QDs/Si heterojunction composite crystalline silicon wafer having high quantum efficiency

A heterojunction and composite crystal technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., to achieve the effects of improving the minority carrier life, easy control of experimental operating conditions, and simple and fast process operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

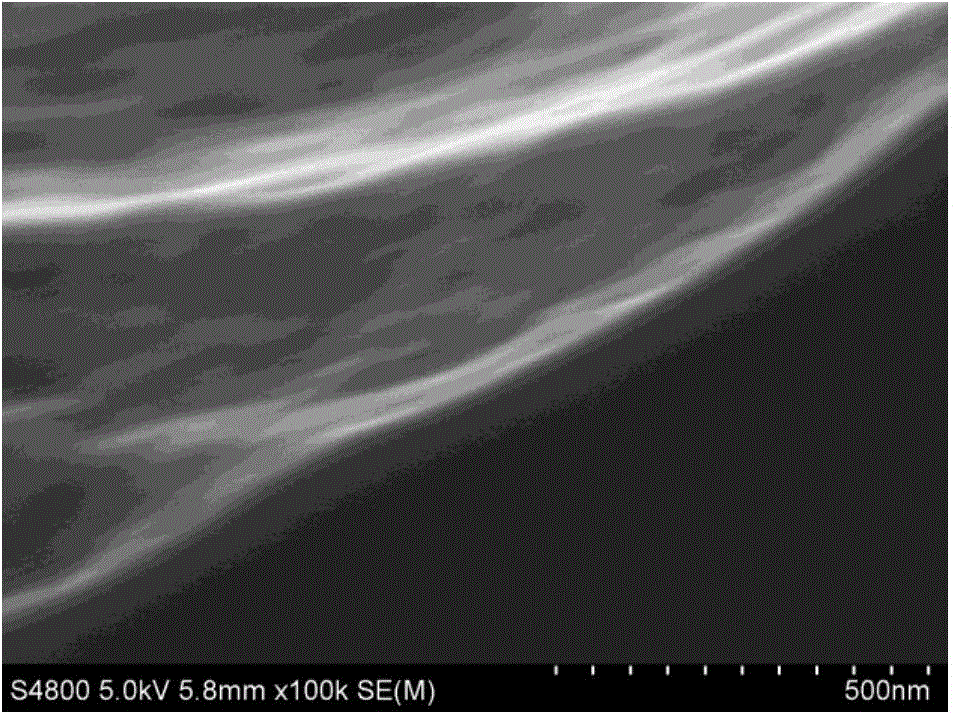

Method used

Image

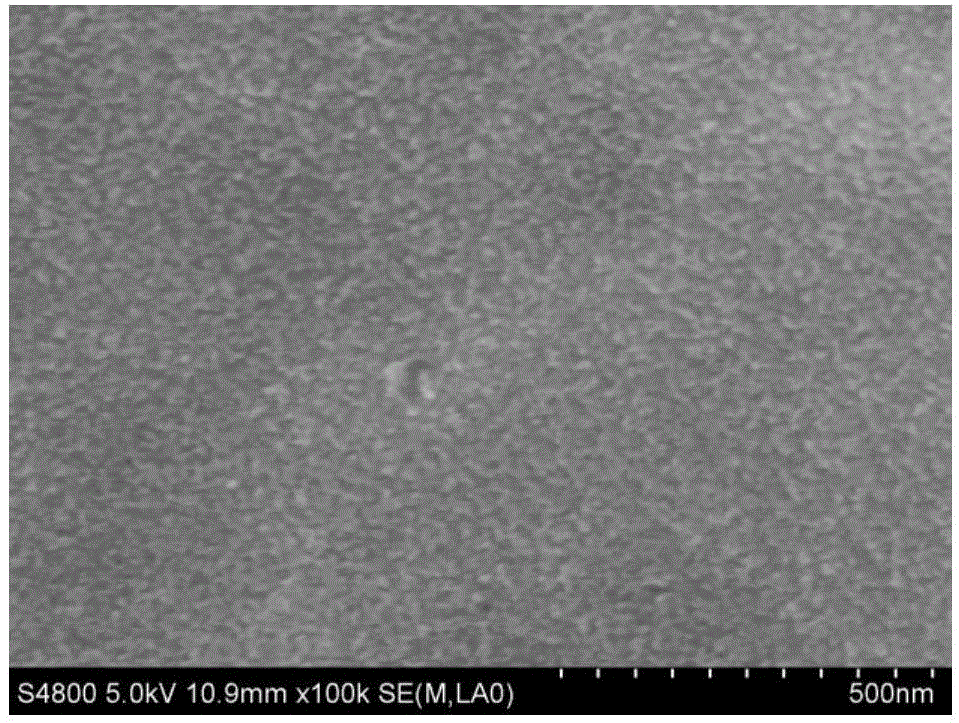

Examples

Embodiment 1

[0027] The preparation method and application of the QDs / Si heterojunction composite silicon wafer with high quantum efficiency provided in this embodiment, the specific steps are as follows:

[0028] (a) Prepare a 1mol / L pretreatment solution; measure a certain amount of 40% hydrofluoric acid, add a certain amount of distilled water, so that the concentration of the hydrofluoric acid is 1mol / L.

[0029] (b) Prepare metal source solution; weigh a certain amount of tin tetrachloride, add distilled water and stir evenly. Make the tin tetrachloride concentration 0.001mol / L.

[0030] (c) Immerse the battery sheet in the pretreatment solution for 15 seconds, take it out, and drain it; then immerse it in the metal source solution for 15 seconds, take it out, and drain it.

[0031] (d) Treat in a high temperature furnace at 800°C for 5 minutes.

Embodiment 2

[0033] The preparation method of this example is the same as that of Example 1, except that in step (a), the concentration of hydrofluoric acid in the pretreatment liquid is 0.5 mol / L.

Embodiment 3

[0035] The preparation method of this example is the same as that of Example 1, except that in step (a), the concentration of hydrofluoric acid in the pretreatment liquid is 2 mol / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com