Nd-graphene composite material and preparation method and application thereof

A composite material and graphene technology, applied in the direction of graphene, chemical instruments and methods, metal material coating technology, etc., can solve the problems of difficult application of large-area material production, reduced proton transmission efficiency, poor hydrogen evolution performance, etc., to achieve improved Electrochemical active area, uniform surface morphology, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of Nd-graphene composite material, comprises the following steps:

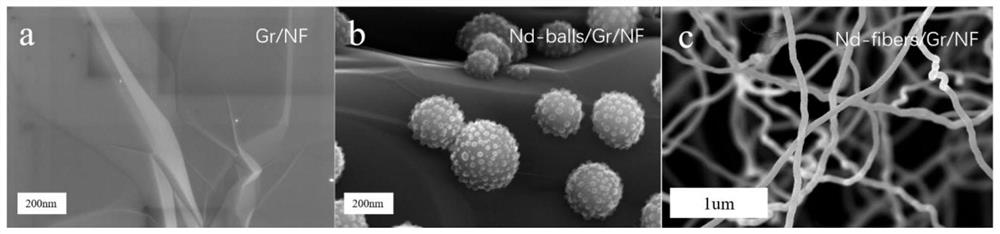

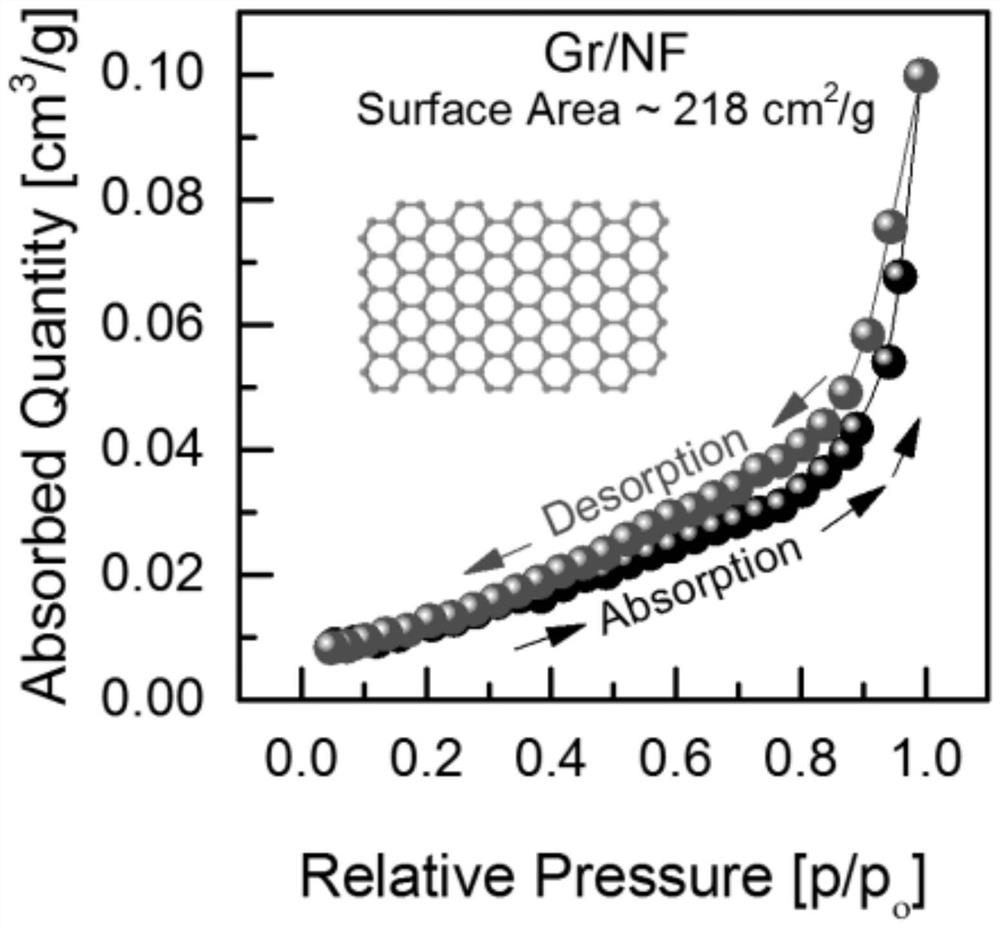

[0030] S1. With nickel foam as the substrate and carbon-containing gas as the carbon source, graphene is grown on the surface of the nickel foam substrate by chemical vapor deposition to obtain a graphene foam nickel material;

[0031] S2. Prepare Nd simple substance on the graphene surface of the graphene foamed nickel material, that is, obtain the Nd-graphene composite material.

[0032] In some embodiments, the preparation of Nd simple substance on the graphene surface of the graphene nickel foam material in S2 specifically includes: placing the graphene foam nickel material in a tube furnace, placing neodymium fluoride powder in the tube furnace and heating to 1200-1400°C, volatilize and decompose neodymium fluoride to produce neodymium-containing simple substances and deposit on the surface of graphene.

[0033] In some embodiments, the preparati...

Embodiment 1

[0048] A kind of preparation method of Nd-graphene composite material, comprises the following steps:

[0049] A1, foam nickel is placed in the ethanol solution of 5% mass concentration and soaks 8min;

[0050] A2, the foamed nickel processed through ethanol is placed in the first temperature zone of the tube furnace, the neodymium fluoride powder is placed in the second temperature zone of the tube furnace, and the hydrogen and argon gas mixture ( The volume ratio of hydrogen to argon is 5:100), raise the temperature of the first temperature zone to 1100°C, raise the temperature of the second temperature zone to 1400°C, and keep it warm for 10 minutes, and then feed ethylene gas with a flow rate of 100 sccm for 10 minutes. Then, both the first temperature zone and the second temperature zone are naturally cooled to room temperature to obtain the Nd-graphene composite material.

[0051] It should be noted that the above-mentioned tube furnace is a conventional tube furnace, a...

Embodiment 2

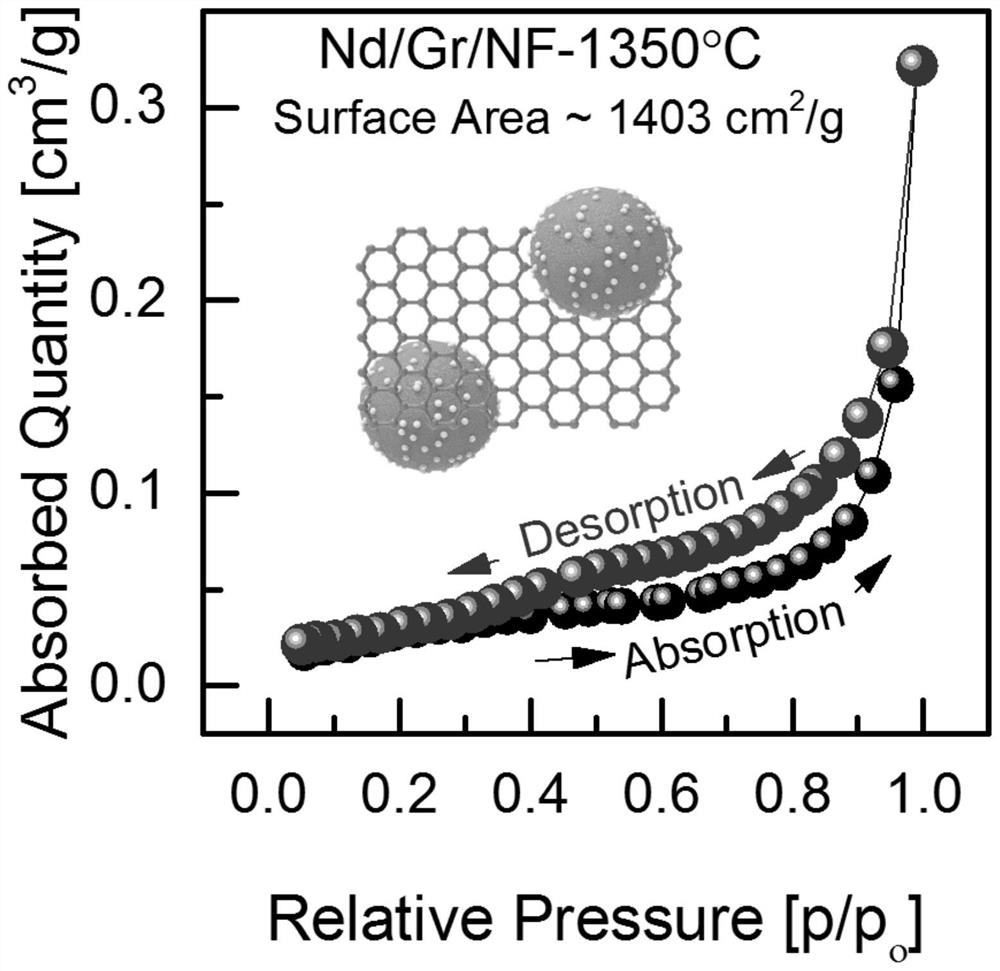

[0053] The preparation method of the Nd-graphene composite material provided in this example is the same as that in Example 1, except that the temperature in the second temperature zone in this example is 1350°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com