Extruder mouth-type plate, use method and extruder adopting mouth-type plate

A die and die technology, which is applied in the field of extruder die plates, can solve the problems of complicated design of extruder heads and inability to frequently replace the die heads, so as to reduce the cost of equipment purchase, simple and convenient installation and transformation, Design easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

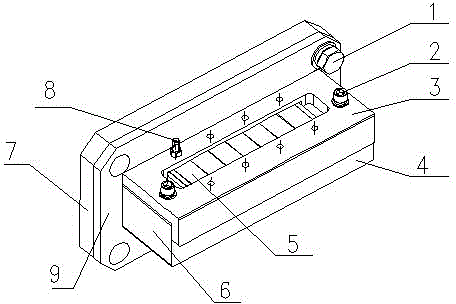

[0022] like figure 1 As shown, an extruder die plate includes a die seat fixed on the machine head 7, a support beam 3 carried by the die seat, and at least two relatively movable adjustment blocks 5 connected to the support beam 3 , the die base is fixed on the machine head 7 by bolts 1, and the die base, support beam 3 and adjustment block 5 jointly form an extrusion port. Each adjustment block 5 is connected to the support beam 3 through adjustment bolts 8 respectively. The cross section of the adjustment block 5 is a square, a rectangle, a right triangle or a right polygon with a smooth transition slope. One or more heating devices are arranged inside the adjustment block 5 . Described lip seat is fixed with machine head 7 by mounting plate 9, and described lip seat side is L-shaped, and its vertical plate 6 is fixedly installed on the mounting plate 9, and its horizontal plate 4 carries support beam 3. Described support beam 3 is fixed on the horizontal plate 4 of die ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com