GQD (graphene quantum dot) sensitized mesoporous Ti coated type GQD@TiO2/CG (conductive glass) visible light catalytic electrode and preparation technology thereof

A technology of graphene quantum dots and preparation process, applied in the direction of physical/chemical process catalyst, chemical/physical process, electrochemical water/sewage treatment, etc., can solve the problem of low photocatalytic activity and photocatalytic efficiency, limit practical application, quantum It can reduce the degradation cost, reduce the production cost, and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

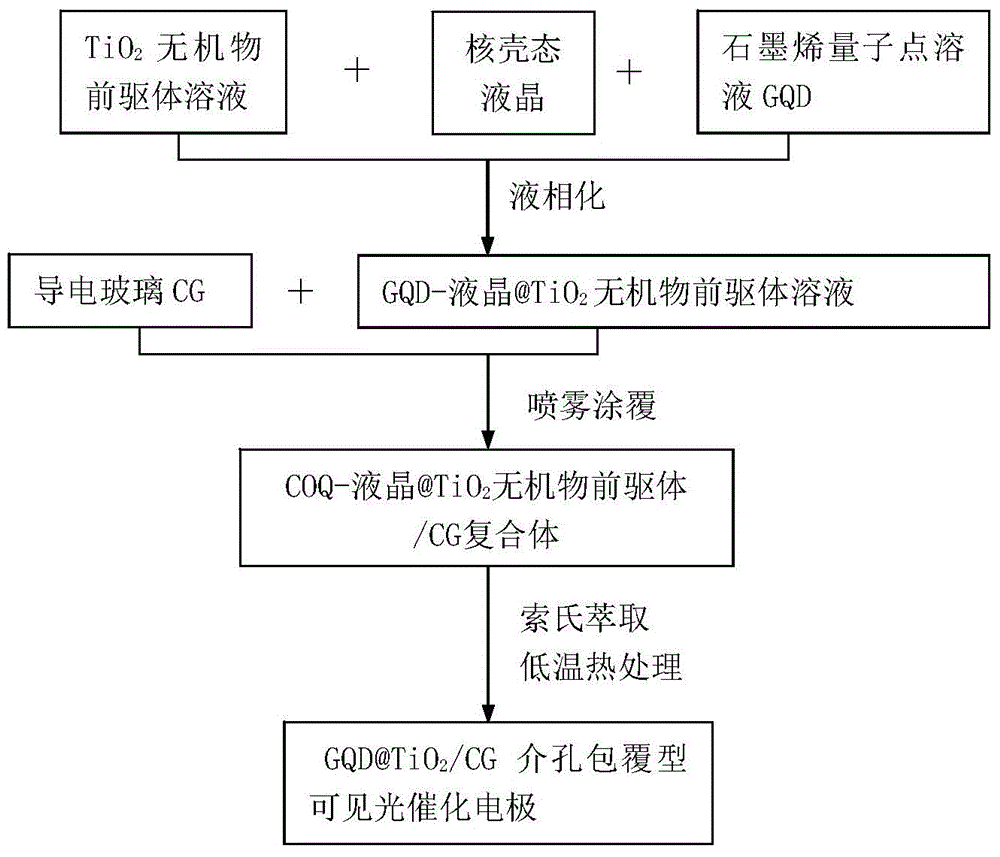

[0045] Example 1: First, using glyceryl monostearate (20g), distilled water (35ml) and graphene quantum dots (50mg) as raw materials, the in-situ The core-shell liquid crystal is synthesized by polymerization technology. Secondly, the liquid phase method is used to mix 60g of titanium tetrachloride with a purity of 99.0%, 60ml of distilled water and 5ml of concentrated hydrochloric acid (37%) to control the pH between 1-3. Add it into a three-necked bottle, and stir well with a GS122 electronic constant speed stirrer. Then add the core-shell liquid crystal into the three-neck flask to form GQD-liquid crystal TiO 2 Inorganic precursor solution; in addition, conductive glass (3cm × 7cm) is put into sprayer, and the optimal distance of nozzle from conductive carbon felt is 60cm, internal temperature 20 ℃, relative humidity 60%, spray pressure 2MPa, spray flow rate 0.01ml / min, spray 3ml / cm per square centimeter on the surface of conductive glass 2 . Obtaining GQD-LC TiO 2 Ino...

Embodiment 2

[0047] Example 2: First, using glyceryl monolaurate (20g), distilled water (35ml) and graphene quantum dots (50mg) as raw materials, under the conditions of a temperature of 50°C, a pressure of 1 atmosphere, and a reaction time of 90min, by in-situ polymerization Technology to synthesize core-shell liquid crystals. Next, use the liquid phase method to mix 60g of titanium tetrachloride with a purity of 99.0%, 60ml of distilled water and 5ml of concentrated hydrochloric acid, control the pH value between 1–3, and add it to a three-necked bottle. , Stir well with a GS122 electronic constant speed stirrer. Then add the core-shell liquid crystal into the three-neck flask to form GQD-liquid crystal TiO 2 Inorganic precursor solution; in addition, conductive glass (3cm × 7cm) is put into sprayer, and the optimal distance of nozzle from conductive carbon felt is 60cm, internal temperature 20 ℃, relative humidity 65%, spray pressure 6MPa, spray flow rate 0.02ml / min, spray 3.5ml / cm pe...

Embodiment 3

[0049] Example 3: First, using glycerol monooleate (20g), distilled water (35ml) and graphene quantum dots (50mg) as raw materials, under the conditions of a temperature of 60°C, a pressure of 1 atmosphere, and a reaction time of 80min, by in-situ polymerization Technology to synthesize core-shell liquid crystals. Next, use the liquid phase method to mix 50g of titanium tetrachloride with a purity of 99.0%, 60ml of distilled water and 5ml of concentrated hydrochloric acid, control the pH value between 1–3, and add it to a three-necked bottle. , Stir well with a GS122 electronic constant speed stirrer. Then add the core-shell liquid crystal into the three-neck flask to form GQD-liquid crystal TiO 2 Inorganic precursor solution; in addition, conductive glass (3cm × 7cm) is put into sprayer, and the optimal distance of nozzle from conductive carbon felt is 60cm, internal temperature 20 ℃, relative humidity 65%, spray pressure 4MPa, spray flow rate 0.03ml / min, spray 4ml / cm per s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com