Photoelectrochemical etching method for removing SiC substrate epitaxial graphene buffer layer

A photoelectrochemical and graphene technology, applied in the field of microelectronic materials, can solve the problems of strong corrosiveness, high risk factor, severe hydrofluoric acid-metal molybdenum reaction process, etc., to achieve high safety factor, safe operation, fixed assets, etc. less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A photoelectrochemical etching method for removing an epitaxial graphene buffer layer on a SiC substrate, comprising steps as follows:

[0039] (1) Polish and clean the 6H-SiC wafer with a diameter of 2 inches after silicon surface polishing, and complete the growth of graphene in a single crystal growth furnace to obtain a 4H / 6H‐SiC substrate epitaxial graphene wafer; the growth temperature is 1650 ℃, the growth time is 60min;

[0040] Heat the electric soldering iron to 120°C and place it on the indium grain to melt the metal indium; place one end of a 15cm-long metal nickel wire in the molten metal indium and let it stand for 0.5min to fix the metal wire on the metal indium grain , as a wire connecting the epitaxial graphene wafer on the 4H / 6H-SiC substrate;

[0041] Weigh 1.000g KOH solid, dissolve in 50mL deionized water, stir evenly with a glass rod, let stand for 4min, and prepare 2wt% KOH etching solution;

[0042] The obtained 4H / 6H-SiC substrate epitaxial gr...

Embodiment 2

[0048] A photoelectrochemical etching method for removing an epitaxial graphene buffer layer on a SiC substrate, comprising steps as follows:

[0049] According to the same graphene growth method as in Example 1, the difference is that a certain amount of KOH is weighed, fully stirred and dissolved in 50 mL of deionized water, and a 3wt% KOH etching solution is prepared.

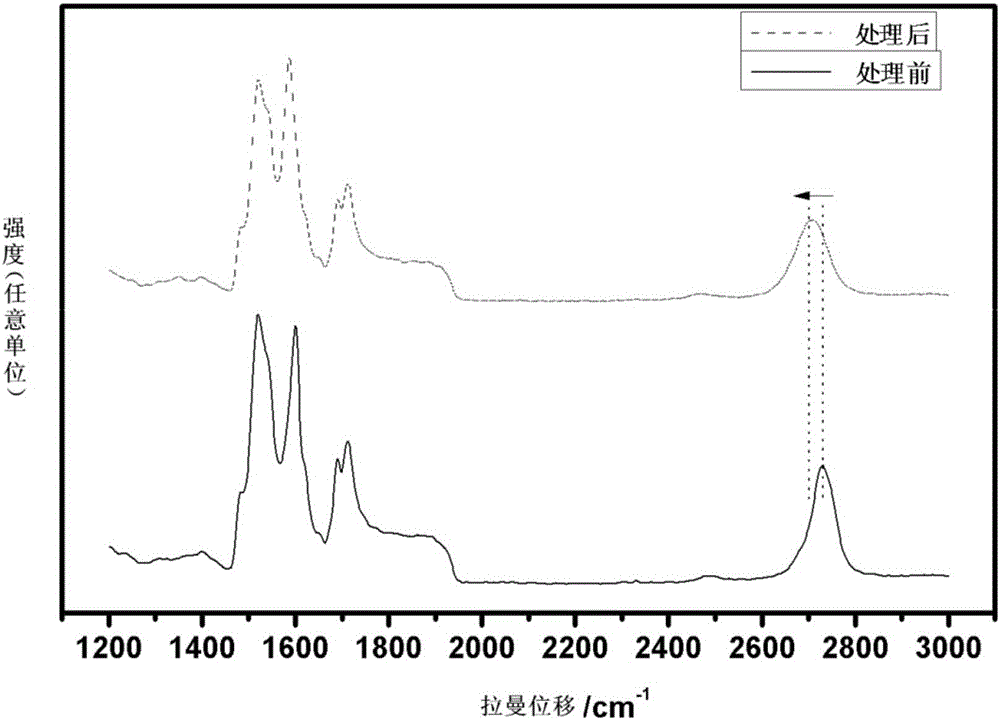

[0050] Graphene material obtained by Raman spectrum and AFM characterization, the 2D peak position is 2672cm -1 , width at half peak is 65.1cm -1 .

Embodiment 3

[0052] A photoelectrochemical etching method for removing an epitaxial graphene buffer layer on a SiC substrate, comprising steps as follows:

[0053] According to the same graphene growth method as in Example 1, the difference is that the three-electrode system is irradiated with ultraviolet light, and the electrolysis time is controlled for 2 hours.

[0054] Graphene material obtained by Raman spectrum and AFM characterization, the 2D peak position is 2682cm ‐1 , width at half peak is 58.3cm ‐1 .

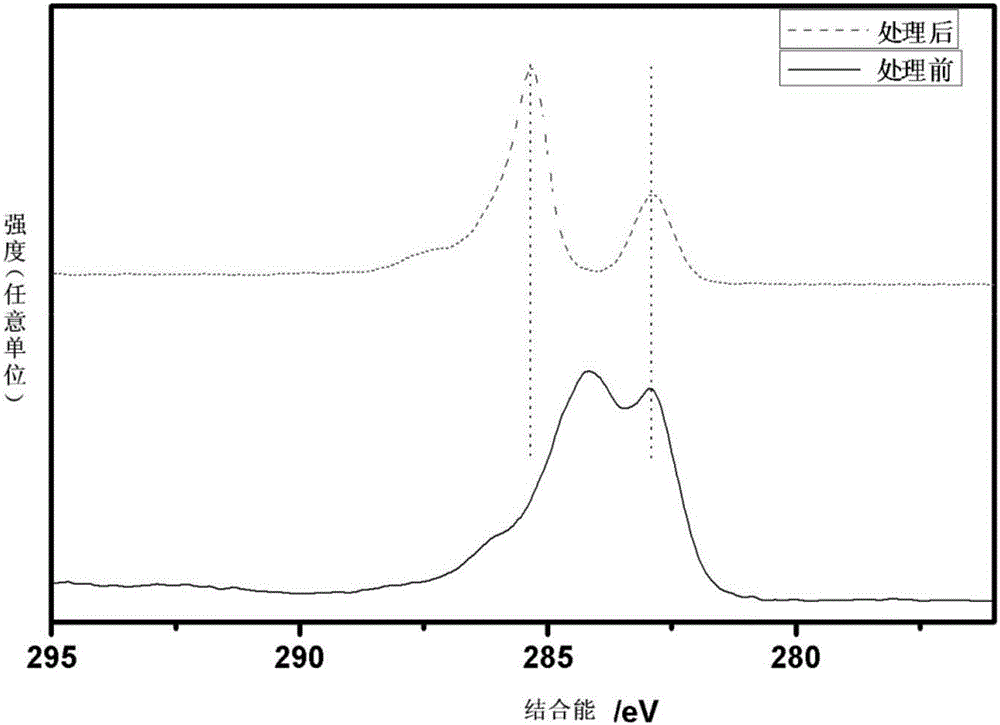

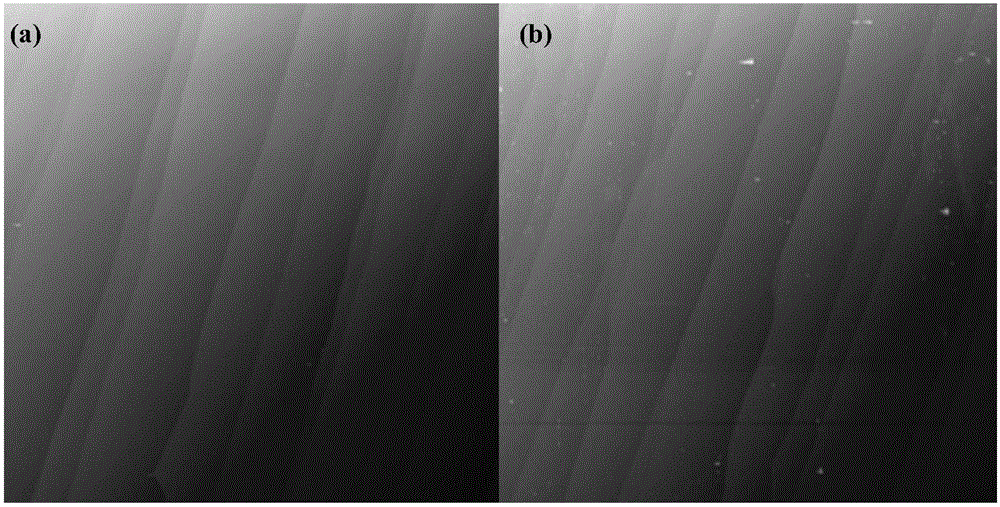

[0055] Through the description of Examples 1-3, in conjunction with the characterization results of graphene materials under the three embodiments, it can be seen that the application of the method of the present invention can eliminate the friction between graphene and the underlying SiC substrate without destroying the surface graphene. Interaction and uniform surface morphology are conducive to improving the performance of graphene materials in the field of electrical devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com