Quantum dot-sensitized graphene base mesoporous coating CdSe @ MT/GR visible light-catalyzing composite nanometer material and preparation method thereof

A composite nanomaterial, quantum dot sensitization technology, applied in the direction of luminescent materials, physical/chemical process catalysts, nanotechnology, etc., to achieve the effects of reduced processing cost, low production cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

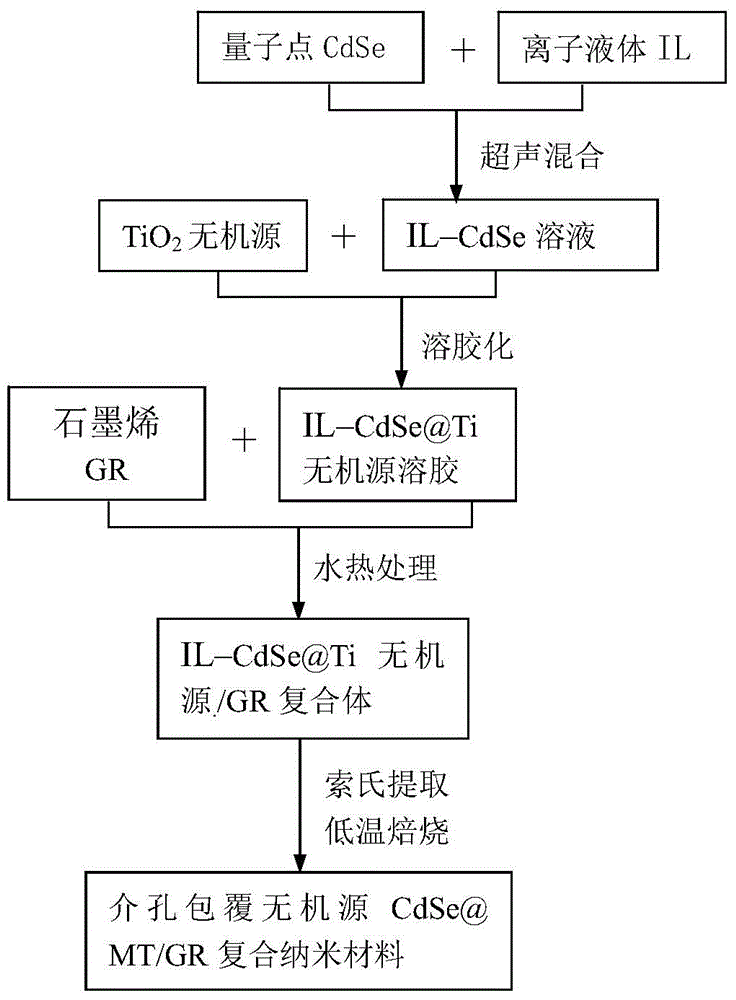

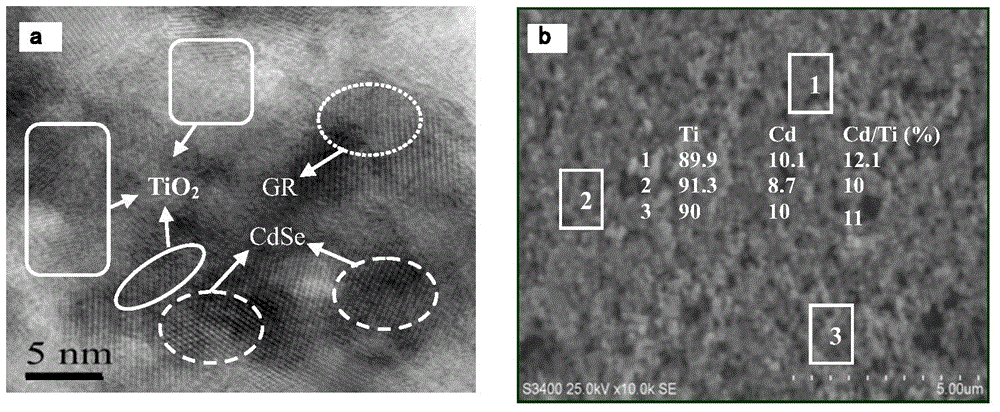

[0042] Embodiment 1: first take octadecene, oleic acid, chloroform, CdO, Se powder as raw material, according to weight ratio octadecene: oleic acid: chloroform: CdO: Se powder=3:5:1:1, by solvothermal CdSe quantum dots were synthesized by stirring for 30 min in oleic acid solvent at a temperature of 70 °C. Using ultrasonic mixing (mixing conditions: time 30min, ultrasonic power 70W), the N-alkylpyridine cation (N-butylpyridine tetrafluoroborate aqueous solution, 20ml, 17mg L -1 ) and the CdSe quantum dots prepared above (30ml, 3umol L -1 ) to form functionalized IL–CdSe. Secondly, introduce the functionalized IL–CdSe into the three-necked flask, and use the dissolution self-assembly process to mix 60 g of butyl titanate with a purity of 99.0% and 2 ml of concentrated hydrochloric acid (37 mass %), and then add it dropwise to the above-mentioned three-necked flask In the process, ultrasonic stirring was continued at 40 °C to form IL–CdSeTi inorganic source sol. Add the IL–C...

Embodiment 2

[0044] Embodiment 2: first take octadecene, oleic acid, chloroform, CdO, Se powder as raw material, according to weight ratio octadecene: oleic acid: chloroform: CdO: Se powder=3:6:1:1.2, by solvothermal CdSe quantum dots were synthesized by stirring for 30 min in oleic acid solvent at a temperature of 70 °C. Using ultrasonic mixing (mixing conditions: time 30min, ultrasonic power 70W), the N-alkylpyridinium cation (N-butylpyridine chloride salt, 20ml, 17mg L -1 ) and the CdSe quantum dots prepared above (30ml, 3umol L -1 ) to form functionalized IL–CdSe. Secondly, the functionalized IL–CdSe was introduced into a three-necked flask, and 60 g of butyl titanate with a purity of 99.0% and 2 ml of concentrated hydrochloric acid (37 mass %) were mixed, and then added dropwise to the three-necked flask In , continue ultrasonic stirring to form IL–CdSeTi inorganic source. Add the IL–CdSeTi inorganic source sol into the hydrothermal reactor, then put 50g graphene into the hydrother...

Embodiment 3

[0046] Embodiment 3: first take octadecene, oleic acid, chloroform, CdO, Se powder as raw material, according to weight ratio octadecene: oleic acid: chloroform: CdO: Se powder=3:5:1:1, by solvothermal CdSe quantum dots were synthesized by stirring for 30 min in oleic acid solvent at a temperature of 70 °C. Using ultrasonic mixing (mixing conditions: time 30min, ultrasonic power 70W), the N-alkylpyridinium cation (N-hexylpyridine chloride salt, 20ml, 17mg L -1 ) and the CdSe quantum dots prepared above (30ml, 3umol L -1 ) to form functionalized IL–CdSe. Secondly, introduce the functionalized IL–CdSe into the three-necked flask, and use the dissolution self-assembly process to mix 60 g of butyl titanate with a purity of 99.0% and 2 ml of concentrated hydrochloric acid, then drop them into the three-necked flask, and continue to stir ultrasonically , forming IL–CdSeTi inorganic source. Add the IL–CdSeTi inorganic source sol into the hydrothermal reactor, then put 50g graphene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com