Carbon nitride supported catalyst and preparation method and application thereof

A supported catalyst and carbon nitride technology, applied in the field of photocatalytic materials, can solve the problems of high cost and complicated preparation process, and achieve the effects of low cost, simple preparation process and efficient degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

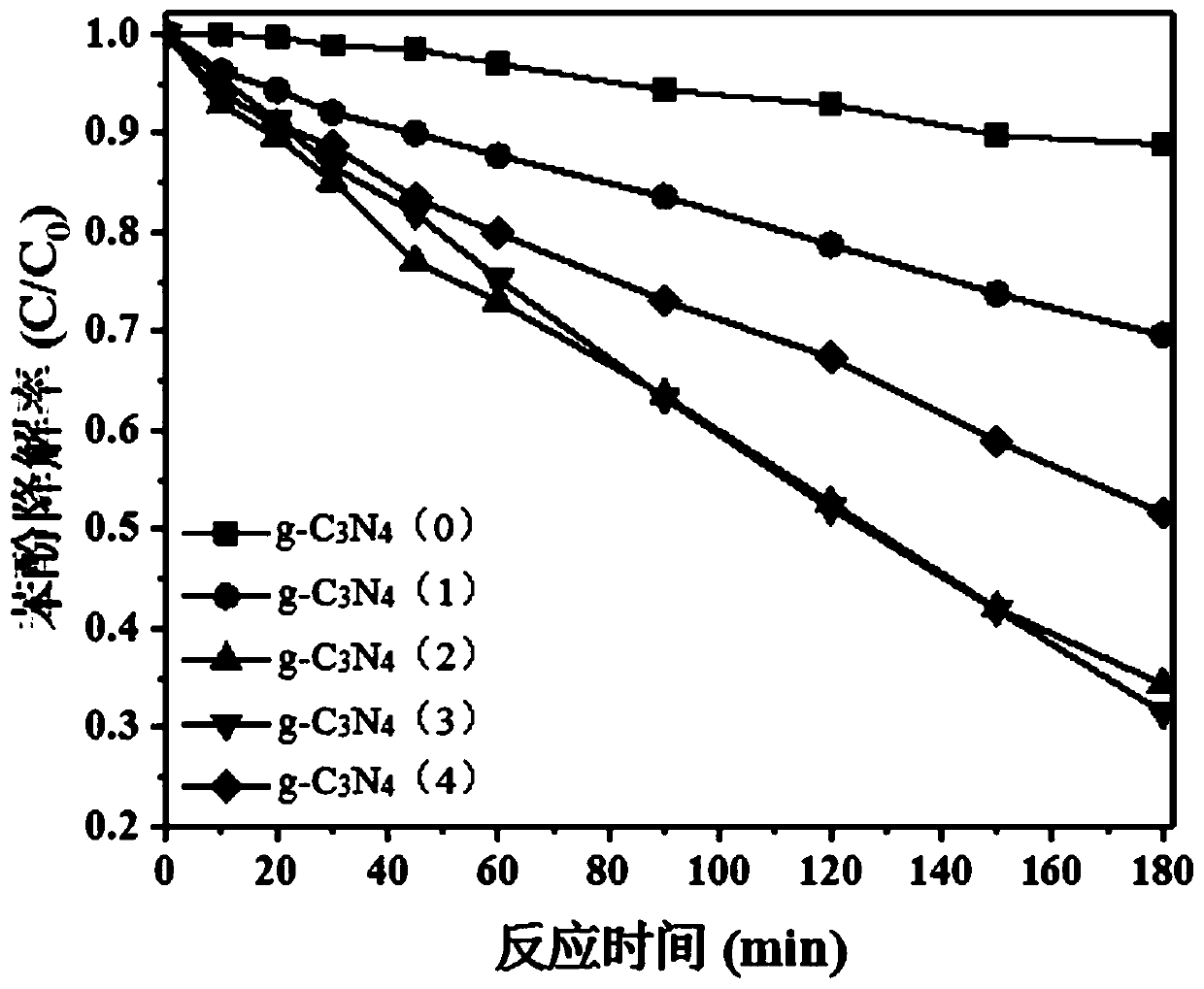

[0056] Embodiment one, g-C 3 N 4 Preparation and degradation test

[0057] 1. Preparation of g-C 3 N 4

[0058] Add 80mL of methanol to the beaker, then add 4g of urea, ultrasonically dissolve the urea, then add 2g of melamine, and ultrasonically disperse it evenly (about 30min) to obtain a mixed solution; stir the mixed solution on a magnetic stirrer at 80°C until Dry, grind the obtained solid product and place it in a muffle furnace for calcination (heat the solid product to 80°C for 1h, then raise the temperature to 550°C for 3h; the heating rate is 2°C / min) to obtain g-C 3 N 4 (about 1.4g), denoted as g-C 3 N 4 (2).

[0059] Change the proportioning of melamine and urea (specifically as shown in table 1), prepare g-C respectively according to the above-mentioned preparation conditions 3 N 4 (0), g-C 3 N 4 (1), g-C 3 N 4 (3), g-C 3 N 4 (4)(g-C 3 N 4 (1), g-C 3 N 4 (3), g-C 3 N 4 (4) with g-C 3 N 4 (2) The morphology and structure are similar):

[00...

Embodiment 2

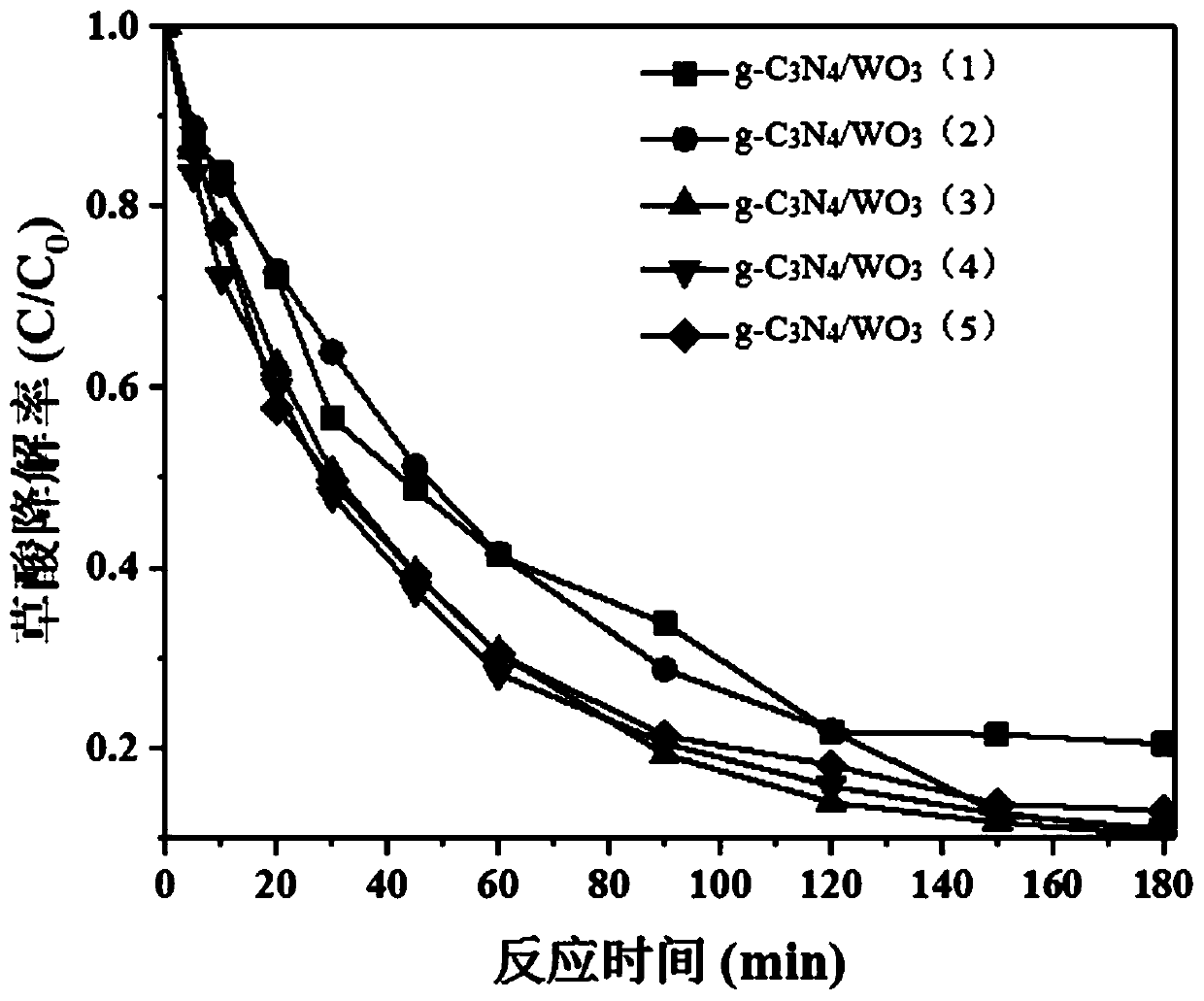

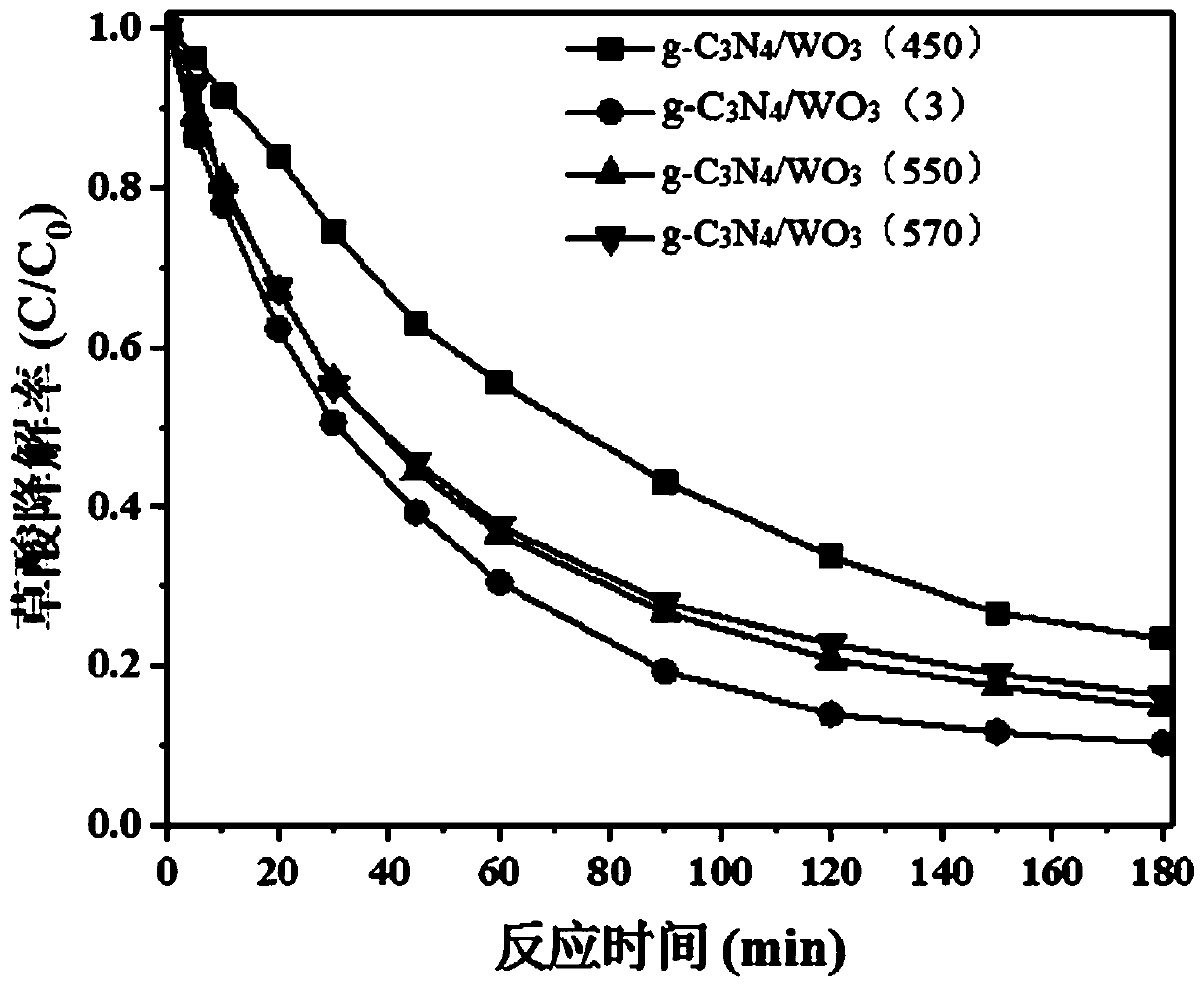

[0067] Embodiment 2, preparation and degradation test of carbon nitride supported catalyst

[0068] 1. Carbon nitride catalyst (g-C 3 N 4 / WO 3 ) preparation

[0069] (1) Preparation of tungstic acid raw material: take 1g sodium tungstate dihydrate (Na 2 WO 4 2H 2 0) Dissolve in 50mL ultrapure water, stir vigorously for 15min, then add 1mL lactic acid, the colorless solution gradually turns light yellow, then vigorously stir for 15min, adjust pH with 3mol / L hydrochloric acid until the solution becomes yellow gel, At this time, the pH meter shows 0.6; continue to stir for 12 hours to obtain tungstic acid raw material.

[0070] (2) Preparation of g-C 3 N 4 / WO 3 :

[0071] Take 3mL tungstic acid and add it to a beaker filled with 50mL ultrapure water, stir evenly on a magnetic stirrer, then add about 1.4g of the above g-C 3 N 4 (2), then place the beaker on a magnetic stirrer and stir at 120°C for 1h (that is, stir until uniform under boiling conditions); then filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com