Preparation method of ceramic membrane with different surface roughness

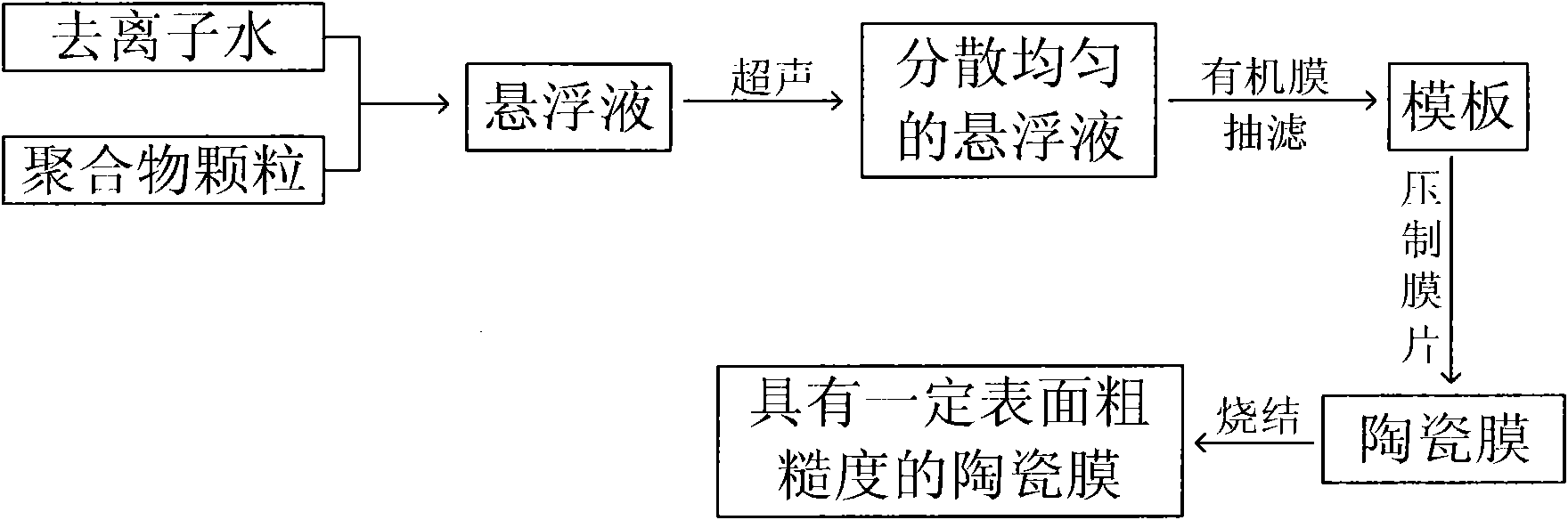

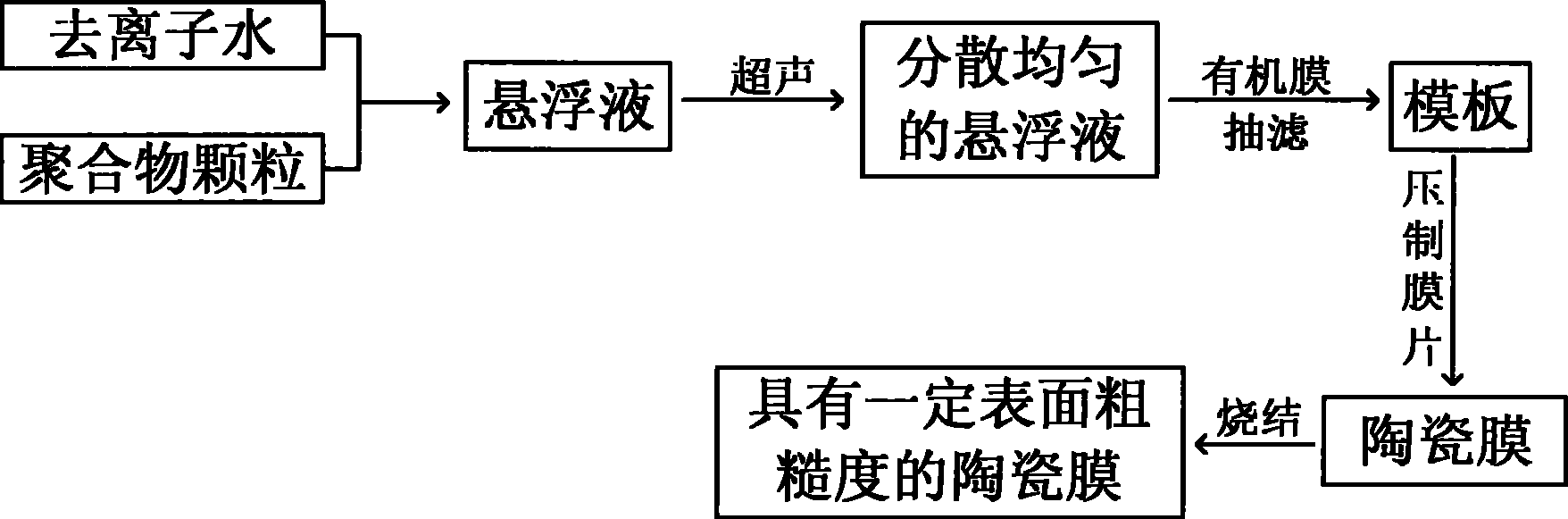

A technology of surface roughness and ceramic membrane, applied in the field of new material preparation, can solve the problems of uneven surface and unsuitable template method, and achieve the effect of simple procedure, rapid preparation and uniform membrane surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

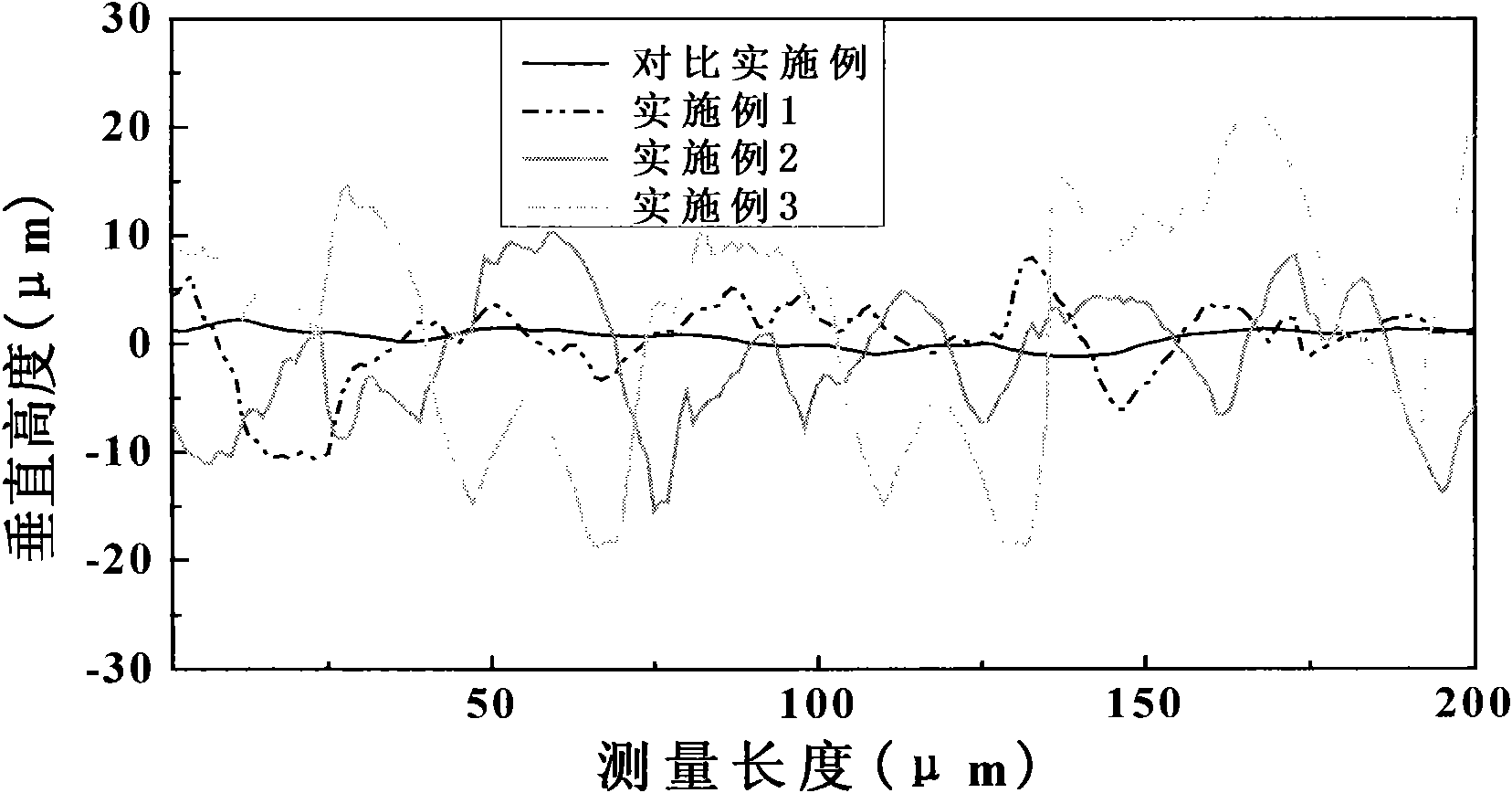

Embodiment 1

[0028] Use 500mL of deionized water and 0.5g of polymethacrylate (PMMA) particles with an average particle size of 0.556μm to prepare a suspension with a concentration of 1g / L, and place the suspension in an ultrasonic instrument with an ultrasonic power of 500W and an ultrasonic frequency of 40KHz. Ultrasound for 35 minutes, and then the average pore size is 0.22μm, the membrane area is 7.1cm 2 The cellulose acetate membrane is the filter membrane, and the circulating water vacuum pump is used to filter 50mL polymethacrylate (PMMA) suspension under the vacuum degree of 0.09MPa, and the suction time is 20 minutes. The cellulose acetate film of the base acrylate (PMMA) layer is placed on the bottom of the mold, and the polymer layer is made upward, and the average particle diameter is 0.5 μm of alumina powder, adding binder PVA accounting for 4% of the powder mass, and then Pour the alumina powder containing PVA on the cellulose acetate film, the amount of alumina powder contai...

Embodiment 2

[0030] Use 500mL of deionized water and 1g of polystyrene (PS) particles with an average particle size of 0.638μm to configure a 2g / L suspension, and ultrasonicate the suspension for 40 minutes in an ultrasonic instrument with an ultrasonic power of 400W and an ultrasonic frequency of 80KHz. Then with an average pore size of 0.35 μm and a membrane area of 7.1 cm 2 The aromatic polyamide membrane is a filter membrane, and a circulating water vacuum pump is used to suction filter 25mL polystyrene (PS) suspension under a vacuum of 0.08MPa. The suction filtration time is 15 minutes, and then the surface with polystyrene (PS) The aromatic polyamide film of PS) layer is placed on the bottom of the mold, and the polymer layer is made upward, adding MC accounting for 6% of the quality of the zirconia powder in the zirconia powder with an average particle size of 0.5 μm, and then adding the MC containing The zirconia powder is poured on the aromatic polyamide film, and the amount of ...

Embodiment 3

[0032] Use 500mL of deionized water and 2g of polypropylene (PP) powder with an average particle size of 0.862 μm to configure a 4g / L suspension, and ultrasonicate the suspension in an ultrasonic instrument with an ultrasonic power of 300W and an ultrasonic frequency of 100KHz for 45 minutes. Then with an average pore size of 0.55 μm and a membrane area of 7.1 cm 2The polyvinyl chloride membrane is the filter membrane, and the circulating water vacuum pump is used to filter 10mL polypropylene (PP) suspension under the vacuum degree of 0.07MPa. The polyvinyl chloride film of the first layer is placed on the bottom of the mold, and the polymer layer is upward, and 8% PEG is added to the zirconia powder with an average particle size of 0.5 μm, and then the powder is poured on the polyvinyl chloride On the membrane, the amount of zirconia powder added with PEG is 0.7g / cm 2 (Based on the bottom area of the mold), use a tablet press to press into a green body under the conditio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com