Micron-nano-sized porous composite material and preparation method thereof

A porous composite material, micro-nano technology, applied in the field of micro-nano porous composite material and its preparation, can solve the problems of time-consuming and immature, and achieve the effect of low thermal conductivity and high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, the preparation of micro-nano porous composite material

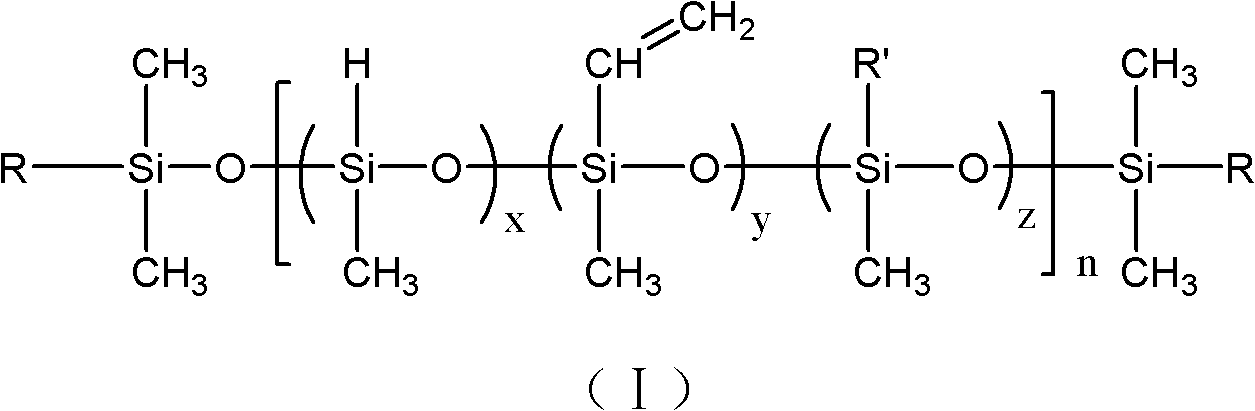

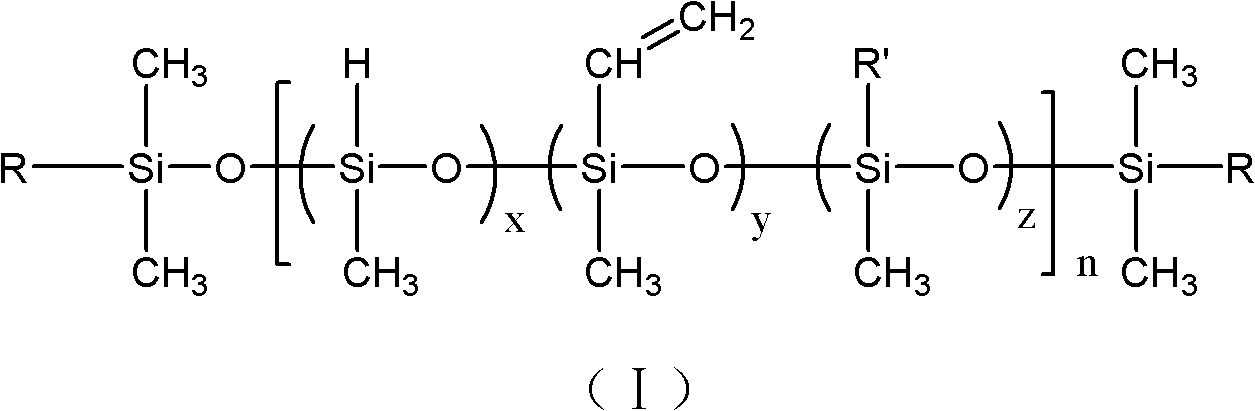

[0024] 10g of methyl vinyl silicone resin and 10g of polymer (R=-OH, R'=Ph, x=0.4, y=0.4, z=0.2, n=20) shown in 10g formula (I) and 380g viscosity is 50 Add the Karstedt platinum catalyst of 0.5 mg after the ball milling of centipoise hydroxyl-terminated methyl silicone oil for 4 h (the amount added is 0.0025% of the total mass of the polymer represented by methyl vinyl silicone resin and formula (I), 0.4 g titanic acid Tetrabutyl (for 2% of the total mass of polymer shown in methyl vinyl silicone resin and formula (I), 0.1g dibutyltin dilaurate (for methyl vinyl silicone resin and formula (I) 0.5% of the total mass of the polymer) mixed evenly, impregnated in 150×150×20mm, density 160Kg / m 3 The mullite fiber needle felt (the quality of the mullite fiber needle felt is 72g, and its mass fraction ratio with the total mass of the polymer shown in methyl vinyl silicone resin and formula (I) is 3.6:1 ...

Embodiment 2

[0025] Embodiment 2, the preparation of micro-nano porous composite material

[0026] Add 3g of chopped glass fiber with a length of 3mm (diameter 9-13μm) (the mass fraction ratio to methylphenyl silicone resin is 0.3:1), add 10g of methylphenyl silicone resin, 3g of particle size 5 Micron mica powder (the ratio of volume and fraction to methylphenylvinyl silicone resin is 0.1:1), 200g of simethicone oil with a viscosity of 10cS, methyltrimethoxysilane, 10mL of xylene, and 0.05g Dibutyltin dilaurate (0.5% of the mass of methylphenyl silicone resin) was stirred and mixed evenly, poured into a mold, vacuumed to remove solvent and air bubbles, and placed in a blast oven at 80°C for 24 hours. Then put it in a high-temperature bell jar furnace protected by argon flow, raise the temperature to 250°C at a rate of 1°C / min and keep it for 1h, and raise the temperature to 400°C at a rate of 0.5°C / min and keep it for 6h to obtain chopped glass fibers The reinforced highly hydrophobic si...

Embodiment 3

[0027] Embodiment 3, the preparation of micro-nano porous composite material

[0028] Mix 1g of vermiculite powder (about 5 μm in particle size, its total volume fraction ratio with methyl silicone resin and polymer represented by formula (I) is 0.5:1) with 10 g of methyl silicone resin, 10 g of formula (I) Polymer (R=-OH, R'=CH 2 CH 2 Si(OMe) 3 , x=0.6, y=0.3, z=0.1, n=200) and 250g viscosity is the simethicone oil of 20cS, 0.4g cobalt naphthenate (for methyl silicone resin and polymer shown in formula (I) 2% of the total mass) mixed by ball milling, stirring and mixing, pouring to a density of 0.1g / cm 3 On about 26g of non-alkali glass fiber mat (the ratio by mass and number of its total mass to the total mass of methyl silicone resin and the polymer represented by formula (I) is 1.3:1), vacuumize and remove air bubbles, place it in 130°C for blasting Keep warm in the oven for 4h. Then place it in a high-temperature bell jar furnace protected by argon flow, raise the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com