Cement base permeating crystallizing waterproof paint formed by reinforcing straw fibers

A technology of infiltrating crystal waterproofing and straw fiber is applied in the field of building materials, which can solve the problems of high price, unsatisfactory secondary impermeability and crack repairing ability of permeable crystalline waterproofing materials, hindering the application of waterproof engineering, etc. Good resistance to tensile deformation, good water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The weight percent of each component of the present embodiment is:

[0039] Portland cement 50%

[0040] Modified magnesite cement 15%

[0041] Filler 21%

[0042] Quartz sand 9%

[0043] Expanded vermiculite powder 0.1%

[0045] Chelating agent 1.3%

[0046] Crystal Precipitant 0.5%

[0047] Calcium ion balancer 2%

[0048] Defoamer 0.1%

[0049] Redispersible latex powder 0.6%

[0050] Water reducing agent 0.3%.

[0051] Among them, the filler is iron tailings slag powder, the calcium ion balancer is calcium hydroxide, the chelating agent is hydroxyethylenediamine tetraacetic acid, the crystallization precipitant is powdery instant sodium fluorosilicate, and the redispersible latex powder is vinyl acetate homopolymer The rubber powder and the superplasticizer are powdered sulfamate superplasticizers.

Embodiment 2

[0053] The weight percent of each component of the present embodiment is:

[0054] Portland cement 60%

[0055] Modified magnesite cement 11%

[0056] Filler 16%

[0057] Quartz sand 7%

[0058] Expanded vermiculite powder 0.2%

[0060] Chelating agent 1.1%

[0061] Crystal Precipitant 0.7%

[0062] Calcium ion balancer 3%

[0063] Defoamer 0.2%

[0064] Redispersible latex powder 0.2%

[0065] Water reducer 0.4%.

[0066] The filler is lead-zinc tailings slag powder, the calcium ion balancer is calcium oxide, the chelating agent is tartaric acid, the crystallization precipitant is powdery instant sodium silicate, and the redispersible latex powder is styrene and butadiene copolymerized rubber powder. The water agent is a powdered sulfamate water reducer.

Embodiment 3

[0068] The weight percent of each component of the present embodiment is:

[0069] Portland cement 40%

[0070] Modified magnesite cement 22%

[0071] Filler 19%

[0072] Quartz sand 10%

[0073] Expanded vermiculite powder 0.3%

[0075] Chelating agent 1.5%

[0076] Crystal Precipitant 1.5%

[0077] Calcium ion balancer 3.8%

[0078] Defoamer 0.3%

[0079] Redispersible latex powder 0.8%

[0080] Water reducing agent 0.6%.

[0081]The filler is blast furnace slag powder, the calcium ion balancer is dihydrate gypsum, the chelating agent is hydroxyethylenediamine tetraacetic acid, the crystallization precipitant is powdery instant sodium fluorosilicate, and the redispersible latex powder is vinyl acetate homopolymer. powder, the superplasticizer is naphthalenesulfonate formaldehyde superplasticizer.

[0082]

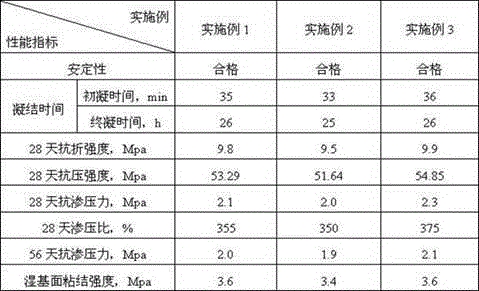

[0083] It can be seen from the above table that the waterproof coating prepared according to the present invention can significant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com