Polyurethane modified organic silicone water-repellency and antibiotic finishing agent, preparation method and application

A technology of polyurethane modification and antibacterial finishing agent, which is applied in fiber treatment, biochemical fiber treatment, and liquid repellent fibers, etc., can solve problems such as delaying spoilage time, increase self-emulsifying ability, improve water repellency effect, and improve high efficiency. The effect of antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

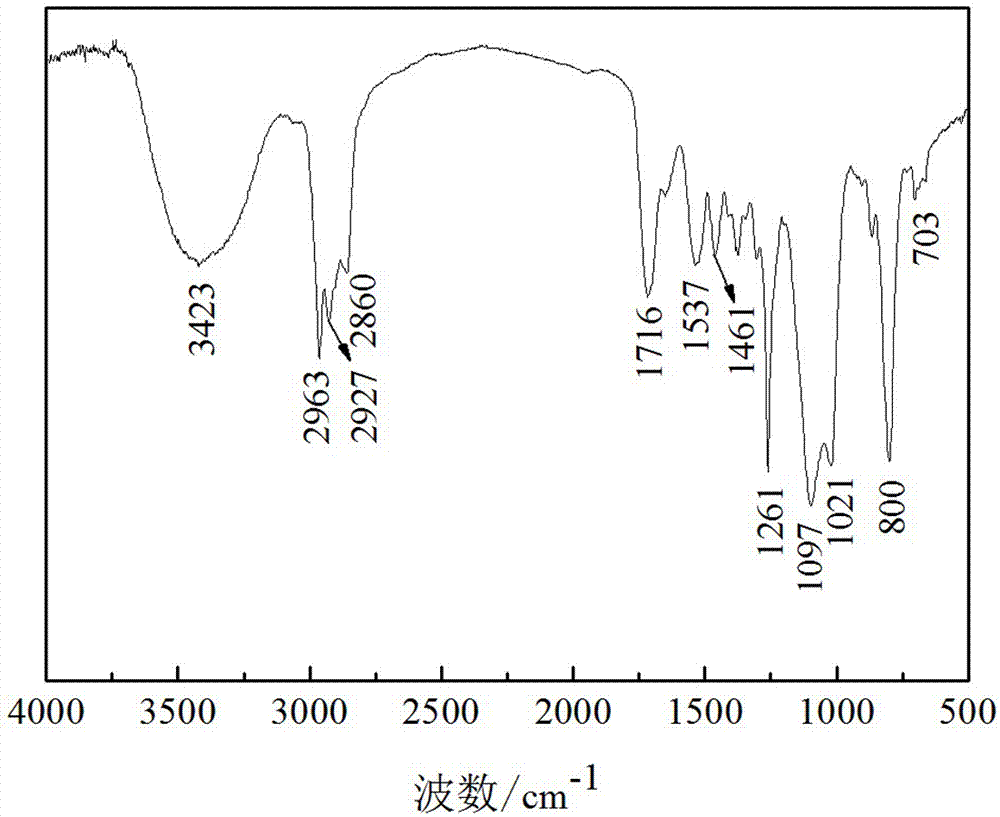

Embodiment 1

[0023] (1) Add 100g of polypropylene glycol 2000, 18g of glyceryl monostearate and 38g of tetrahydrofuran solution containing 0.043g of dibutyltin dilaurate that have been dehydrated and dried into a reaction vessel equipped with a thermometer and a condensation reflux device, and turn on Stir, heat to 55°C under nitrogen atmosphere, slowly add 72g of isophorone diisocyanate dropwise within 2 to 3 hours, raise the temperature to 85°C for 3 hours after the dropwise addition, then cool down to 50°C, add 28g of isophorone diisocyanate dropwise 24g N-methyl-N-benzyl-N,N-dihydroxyethylammonium chloride and 3.7g hydroxyethylhexahydro-s-triazine solution dissolved in tetrahydrofuran, chain extension and crosslinking reaction for 3 hours, to obtain isocyanate group-terminated Polyurethane prepolymer, the -NCO content of the prepolymer measured by the di-n-butylamine method is 0.88%.

[0024] (2) In the reaction vessel, add 180g of double-ended hydroxypropyl polysiloxane 6000 dissolved...

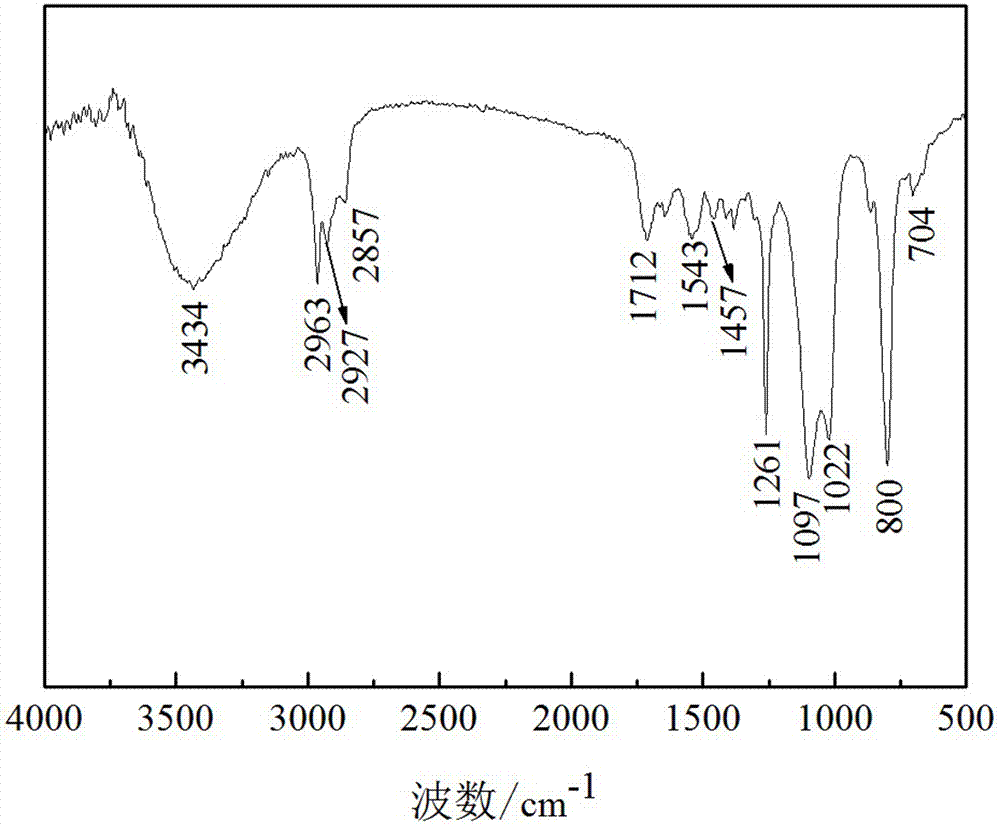

Embodiment 2

[0027] (1) Add 75g of polypropylene glycol 1500, 13.5g of glyceryl monostearate and 27g of tetrahydrofuran solution containing 0.019g of dibutyltin dilaurate after dehydration and drying into a reaction vessel equipped with a thermometer and a condensing reflux device, Start stirring, heat to 60°C under nitrogen atmosphere, slowly add 62g of isophorone diisocyanate dropwise within 2~3 hours, after the dropwise addition, raise the temperature to 85°C and keep it warm for 3 hours, then cool down to 55°C, dropwise 27g of N-methyl-N-benzyl-N,N-dihydroxyethylammonium chloride and 3.7g of hydroxyethylhexahydro-s-triazine solution dissolved in 27g of tetrahydrofuran, chain extension and cross-linking reaction for 3 hours, to obtain isocyanate group-capped The terminal polyurethane prepolymer, the -NCO content of the prepolymer measured by the di-n-butylamine method is 1.09%.

[0028] (2) In the reaction vessel, add 190g of double-ended hydroxypropyl polysiloxane 6000 dissolved in 70g...

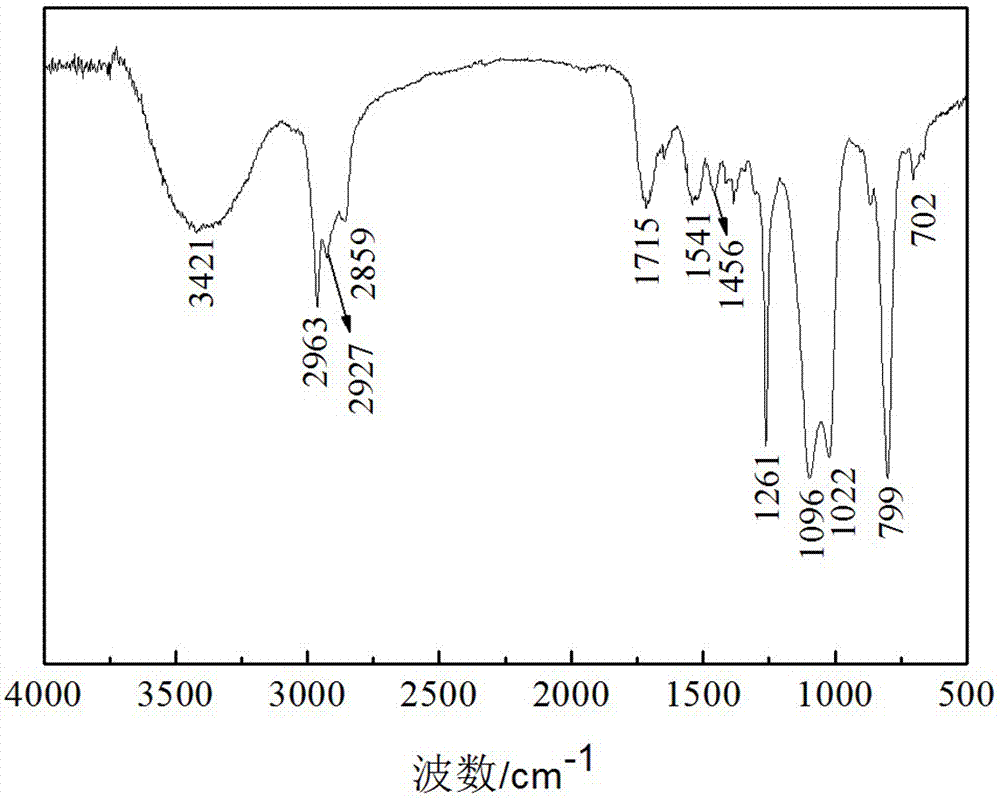

Embodiment 3

[0031] (1) Add 100g of polypropylene glycol 2000, 9g of glyceryl monostearate and 42g of tetrahydrofuran solution containing 0.032g of dibutyltin dilaurate that have been dehydrated and dried into a reaction vessel equipped with a thermometer and a condensation reflux device, and turn on Stir, heat to 58°C under nitrogen atmosphere, slowly add 67g of isophorone diisocyanate dropwise within 2~3 hours, raise the temperature to 80°C for 4 hours, then cool down to 55°C, dropwise add 21g of isophorone diisocyanate 30g of N-methyl-N-benzyl-N,N-dihydroxyethylammonium chloride and 3.7g of hydroxyethylhexahydro-s-triazine solution dissolved in tetrahydrofuran, chain extension and cross-linking reaction for 2 hours, to obtain isocyanate group-terminated Polyurethane prepolymer, the -NCO content of the prepolymer measured by the di-n-butylamine method is 0.97%.

[0032] (2) In the reaction vessel, add 173g of double-ended hydroxypropylpolysiloxane 5000 dissolved in 80g of tetrahydrofuran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com