Water- and oil-repellent composition

A technology of polymer and oil agent, which is applied in the direction of water-repellent addition, textiles and papermaking, and liquid-repellent fibers, etc. It can solve the problems of polymers that cannot meet the performance and low crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0156] The present invention is now explained in detail by way of Examples, Comparative Examples and Test Examples. However, the present invention is not limited to these.

[0157] In the following Examples, Comparative Examples and Test Examples, parts and percentages are by weight unless otherwise specified.

[0158] The test procedure was carried out as follows.

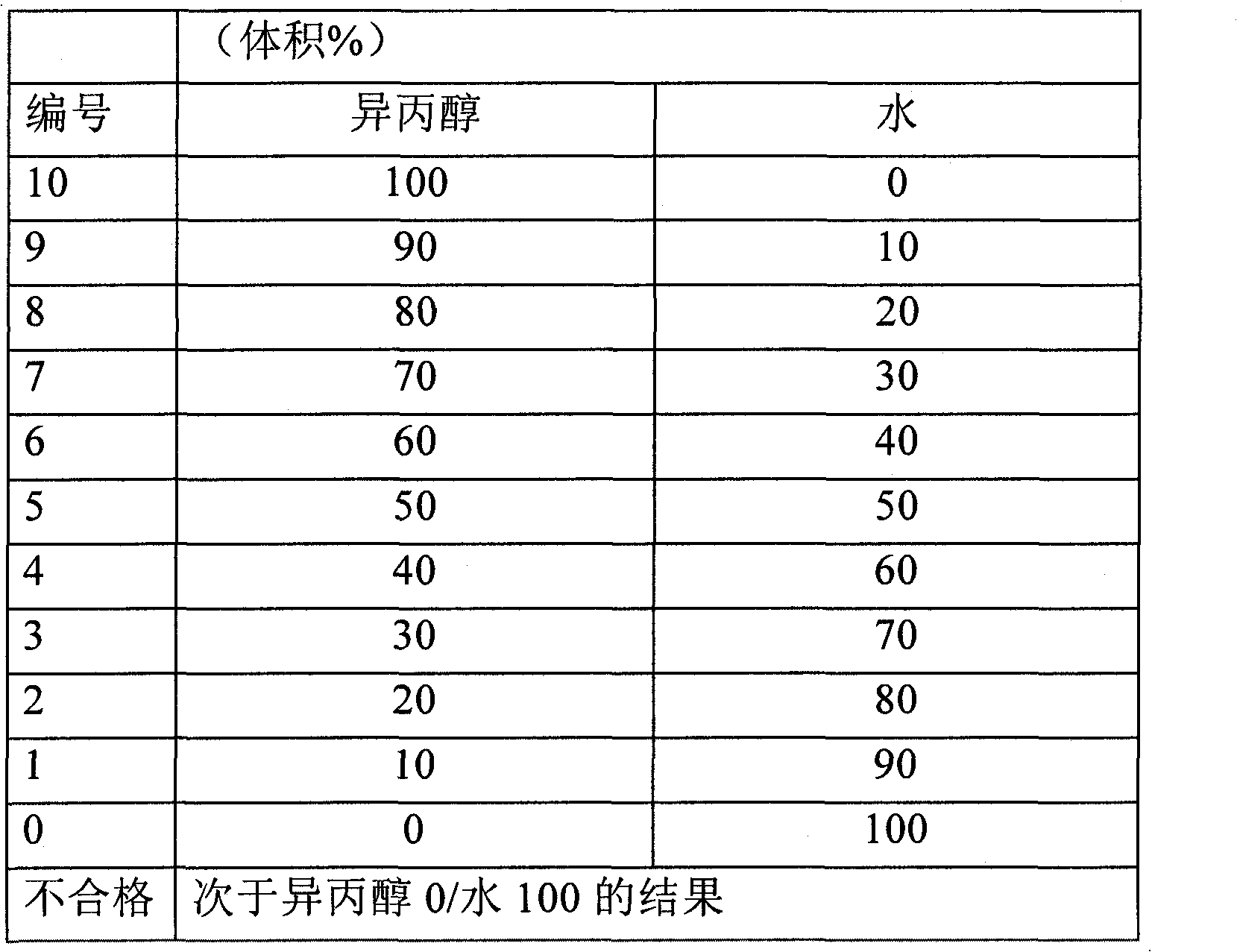

[0159] Water repellency test

[0160] The treated fabrics were kept in a thermo-hygrostat at a temperature of 21°C and a humidity of 65% for at least 4 hours. Test liquids (isopropanol (IPA), water, and mixtures thereof, as indicated in Table 2) that had been stored at 21°C were used. The test was carried out in an air-conditioned room with a temperature of 21°C and a humidity of 65%. A drop of 0.05 mL of the test liquid is gently dripped onto the fabric through a micropipette. The test liquid passed the test if droplets remained on the fabric after standing for 30 seconds. Water repellency is expressed as...

preparation example 1

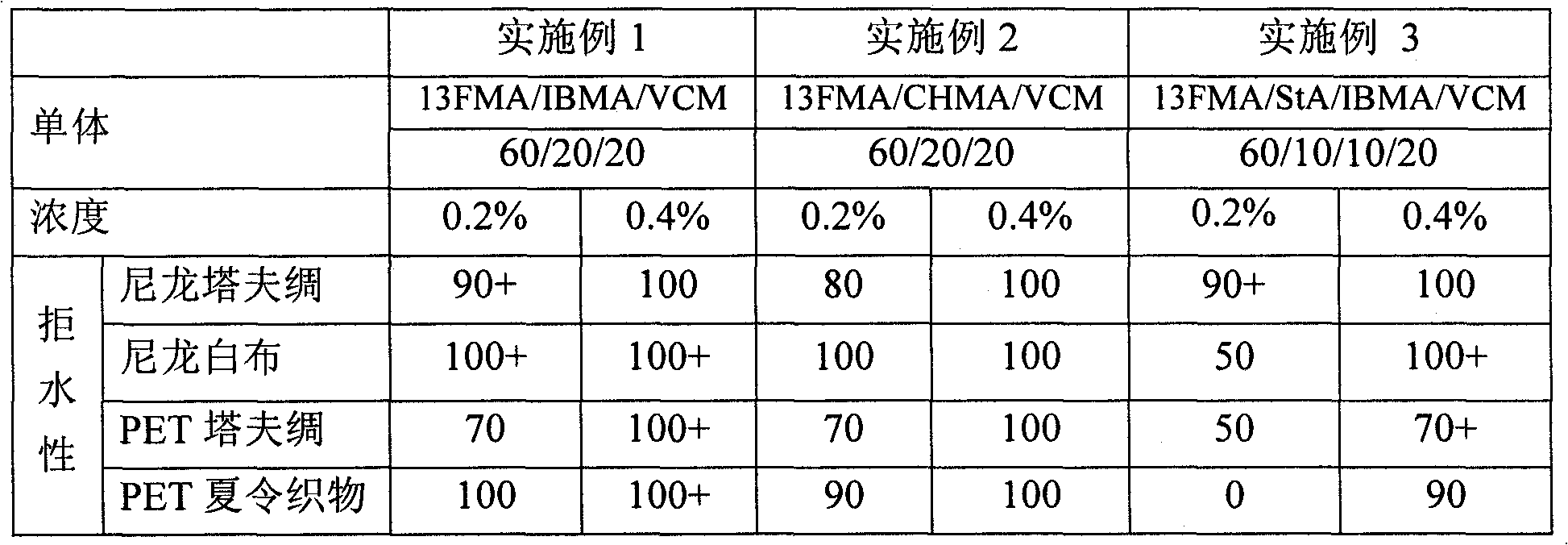

[0166] In a 1 liter autoclave, charge CF 3 CF 2 -(CF 2 CF 2 ) n -CH 2 CH 2 OCOC (CH 3 )=CH 2 (n=2.0) (13FMA) (78.4g), isobornyl methacrylate (IBMA) (26.0g), pure water (250g), tripropylene glycol (35.1g), polyoxyethylene oleyl ether (5.4g) and polyoxyethylene isotridecyl ether (5.4 g) and stirred at a temperature of 60° C. for 15 minutes, and then ultrasonically emulsified and dispersed. After replacing the atmosphere in the autoclave with nitrogen, vinyl chloride (VCM) (30 g) was charged by injection. Furthermore, 2,2-azobis-(2-amidinopropane) dihydrochloride (0.91 g) was added to conduct a reaction at 60° C. for 5 hours, and an aqueous dispersion of a polymer was obtained. The composition (weight ratio) of monomers in the obtained polymer was 13FMA / IBMA / VCM=60 / 20 / 20.

preparation example 2

[0168] In a 1 liter autoclave, charge CF 3 CF 2 -(CF 2 CF 2 ) n -CH 2 CH 2 OCOC (CH 3 )=CH 2 (n=2.0) (13FMA) (78.4g), cyclohexyl methacrylate (CHMA) (26.0g), pure water (250g), tripropylene glycol (35.1g), polyoxyethylene oleyl ether (5.4g) and polyoxyethylene isotridecyl ether (5.4 g) and stirred at a temperature of 60° C. for 15 minutes, and then ultrasonically emulsified and dispersed. After replacing the atmosphere in the autoclave with nitrogen, vinyl chloride (VCM) (30 g) was charged by injection. Furthermore, 2,2-azobis-(2-amidinopropane) dihydrochloride (0.91 g) was added to conduct a reaction at 60° C. for 5 hours, and an aqueous dispersion of a polymer was obtained. The composition (weight ratio) of monomers in the obtained polymer was 13FMA / CHMA / VCM=60 / 20 / 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com