Preparation and application of perfluoro-short-carbon-chain-containing water-repellent oil-repellent finishing agent

A perfluorinated short carbon chain, water-repellent and oil-repellent technology, which is applied in fiber processing, textiles, papermaking, plant fibers, etc., can solve the problems of short carbon chains and lack of oil repellency, and achieve good stability, good air permeability, The effect of simple finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

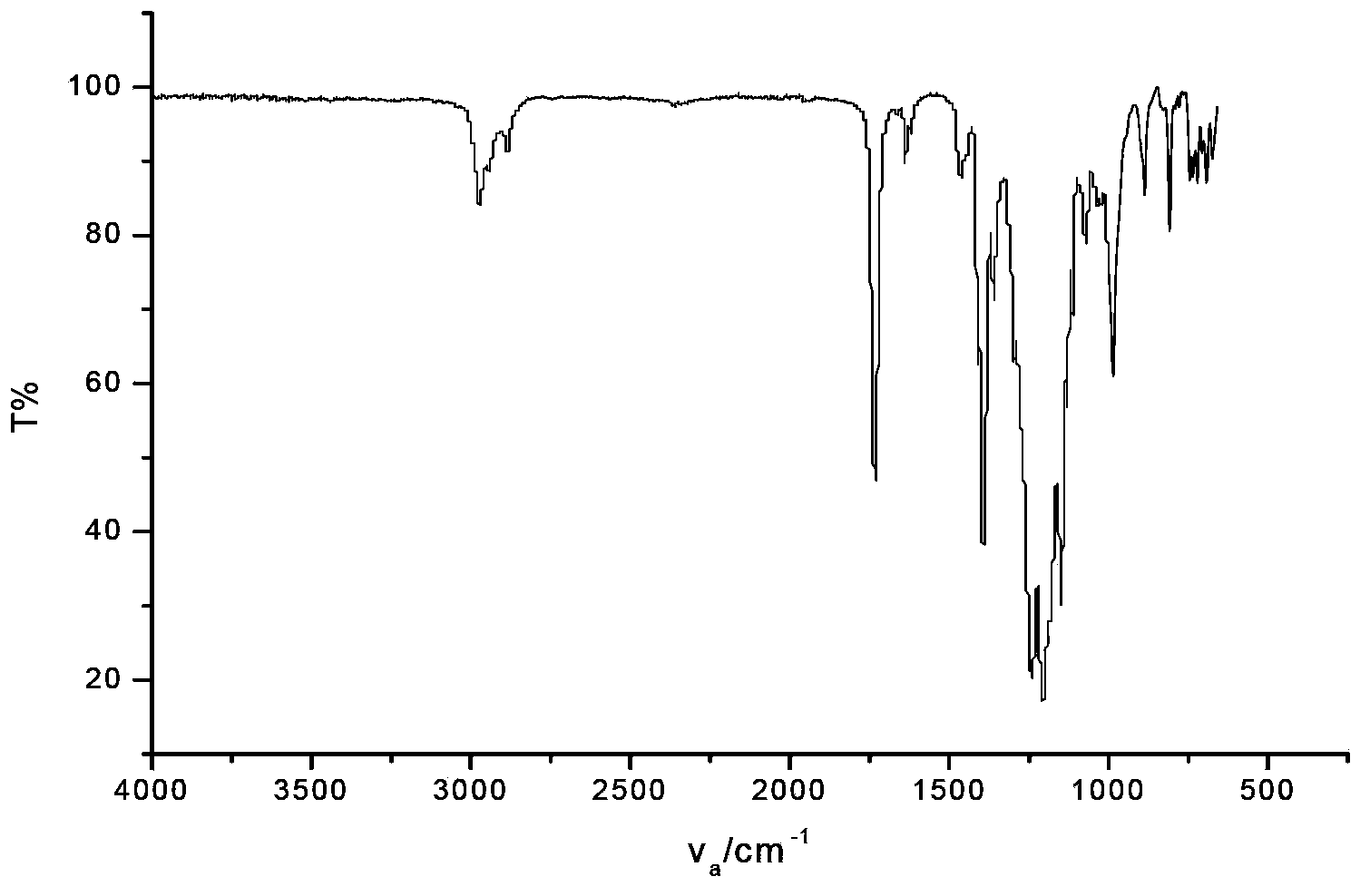

Image

Examples

Embodiment 1

[0032] Preparation of perfluorinated short carbon chain acrylic monomers:

[0033] Dissolve the crude cuprous chloride solid in concentrated hydrochloric acid, then dilute it with distilled water to obtain a white precipitate, filter it, wash it with water three times, wash it several times with absolute ethanol and absolute ether, and dry it for later use.

[0034] Add 4.85g (0.01mol) of dry N-propyl-N-hydroxyethylperfluorohexylsulfonamide to a 100mL three-necked flask, then add 0.05g of newly prepared cuprous chloride and 2.26g (0.025mol) of triethylamine , and then add half the amount of chloroform 15mL to make the three miscible, and the system is a green opaque mixture. The remaining 15 mL of chloroform was mixed with 2.53 g (0.025 mol) of acryloyl chloride, and slowly added to the three-necked flask under ice-bath conditions. During the addition of acryloyl chloride, the temperature in the three-necked flask was kept at 0-5°C.

[0035] After all the acryloyl chloride so...

Embodiment 2

[0038] Preparation of fluorine-containing finishing agent:

[0039] Dissolve 6.14g (11.4mmol) of fluorine-containing acrylic acid monomer, 1.176g (3.6mmol) of stearyl acrylate and 0.056g (0.479mmol) of propylene-2-hydroxyethyl ester in 5mL of acetone with semi-emulsifier (OP-100.132 g; SDS0.074g) were added together into a single-necked flask, heated to 50°C, pre-emulsified for 30 minutes, and used as a pre-emulsified monomer for later use.

[0040]Then add 40mL of water and the remaining half of the emulsifier (OP-100.132g; SDS0.074g) into the three-necked flask, raise the temperature to 50°C, pre-emulsify for 30min, then raise the temperature to 70°C, add half of the initiator APS0.0183g, 4~5min Finally, add 1 / 2 of the spare pre-emulsified monomer in the single-necked flask, and after 0.5h of reaction, add the remaining 1 / 2 pre-emulsified monomer in the single-necked flask. And at the same time slowly add the remaining initiator APS0.0183g. After the dropwise addition, con...

Embodiment 3

[0042] Take an appropriate amount of the emulsion-like finishing agent prepared in Example 2, immerse the pure cotton fabric in the emulsion for 30 minutes, after two dipping and two padding (liquid retention rate 80%), pre-dry at 100°C for 2 minutes, and then dry at 160°C Bake for 2 minutes and cool to room temperature. The water resistance test is carried out according to 3M-II-1988, and the oil resistance test is carried out according to AATCC118-2002. The waterproof level of the fabric is 6, and the oil resistance level of the fabric is 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com