Anti-raise specialistic floor and production method thereof

A production method and flooring technology, applied to layered products, floors, buildings, etc., can solve the problems of floor moisture content changes, solid wood floor warping, deformation, etc., to achieve clear texture, prevent moisture from entering and discharging, and visually good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

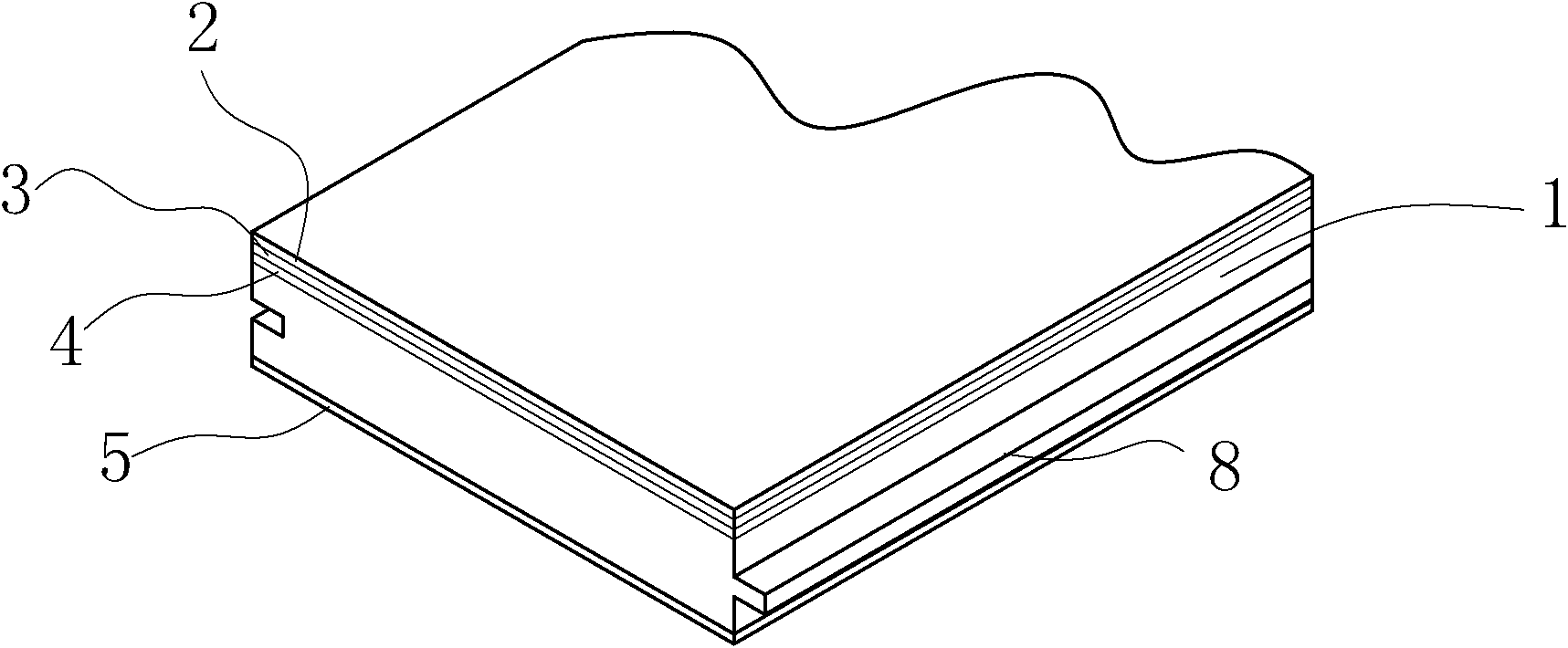

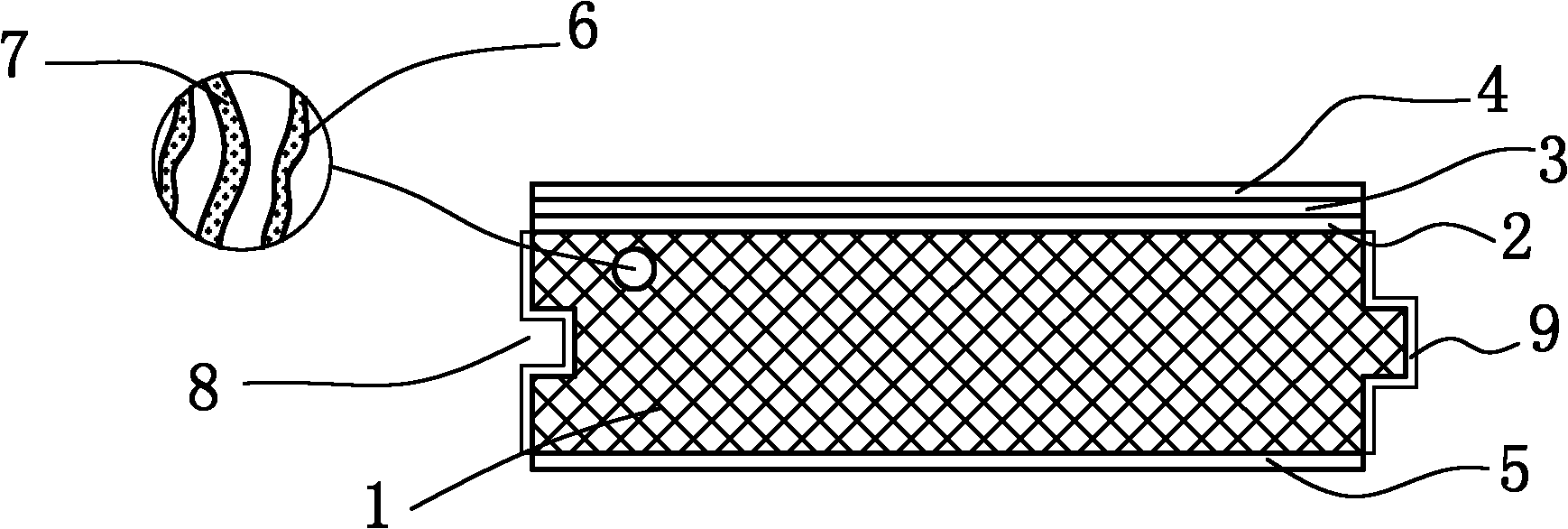

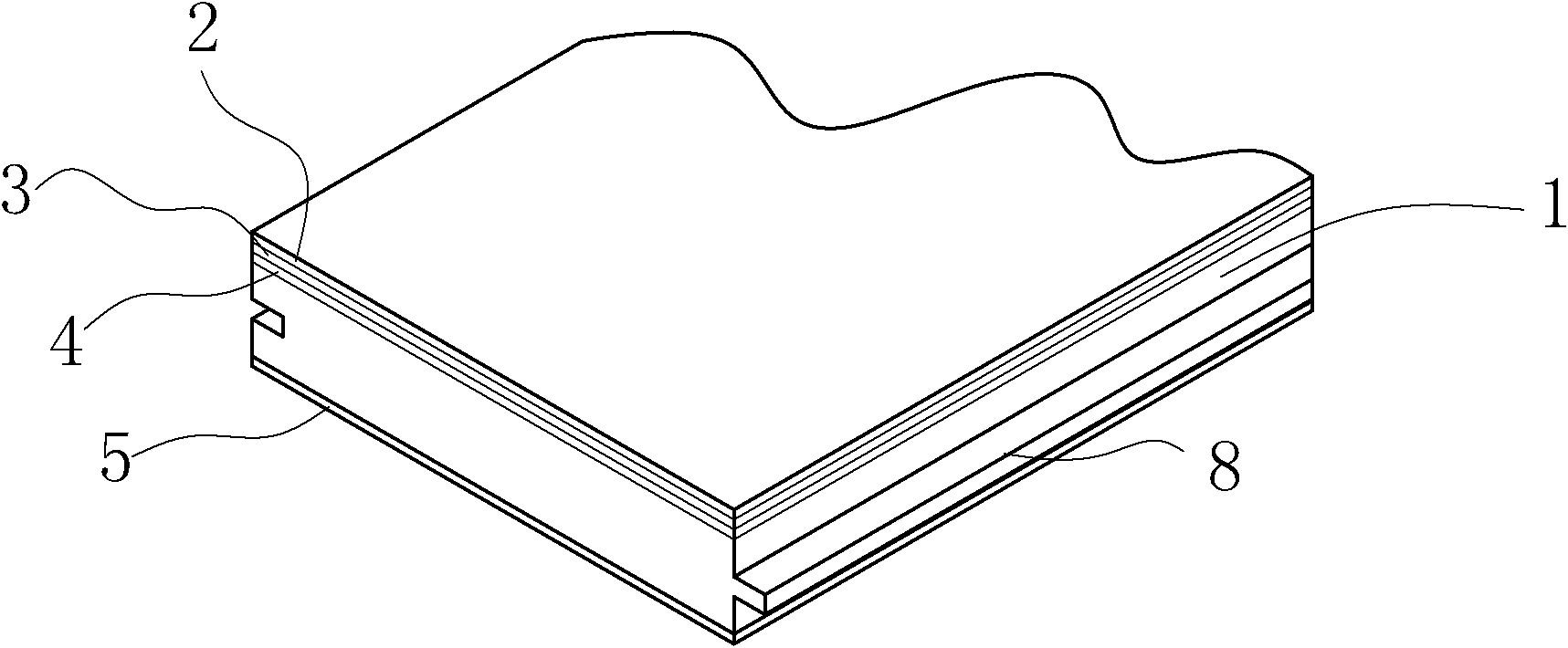

[0035] Example. An anti-warping expert flooring such as figure 1 , 2 As shown, including a substrate 1, a surface paint layer 2, a resin layer 3 and a primer layer 4 are sequentially laid on the top of the substrate 1 from top to bottom, and a back paint layer 5 is laid on the bottom of the substrate 1; the wood fiber conduit 6 of the substrate 1 Resin 7 is filled in the middle; a tongue and groove 8 is opened on the substrate 1, and a wax layer 9 is laid on the surface of the groove 8; the thickness of the surface paint layer 3 is the same as that of the resin 7 filled in the wood fiber conduit 6 of the substrate 2.

[0036] The production method of the above-mentioned anti-warping expert floor, the method comprises the following production steps;

[0037] a. Slicing and sanding; drying the wood, the drying time is 600 hours; after the drying is completed, carry out health preservation, the time of health preservation is 30 days; after the curing, carry out conventional cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com