Sleeve ring used for protecting chopping board from cracking

A collar and chopping board technology, which is applied in the field of collars for protecting chopping boards from cracking, can solve the problems of insufficient pulling force, poor strength of chopping boards, cracked collars, etc., and achieves the effects of convenient application, cracking protection of chopping boards, and scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with accompanying drawing, the present invention is described in detail:

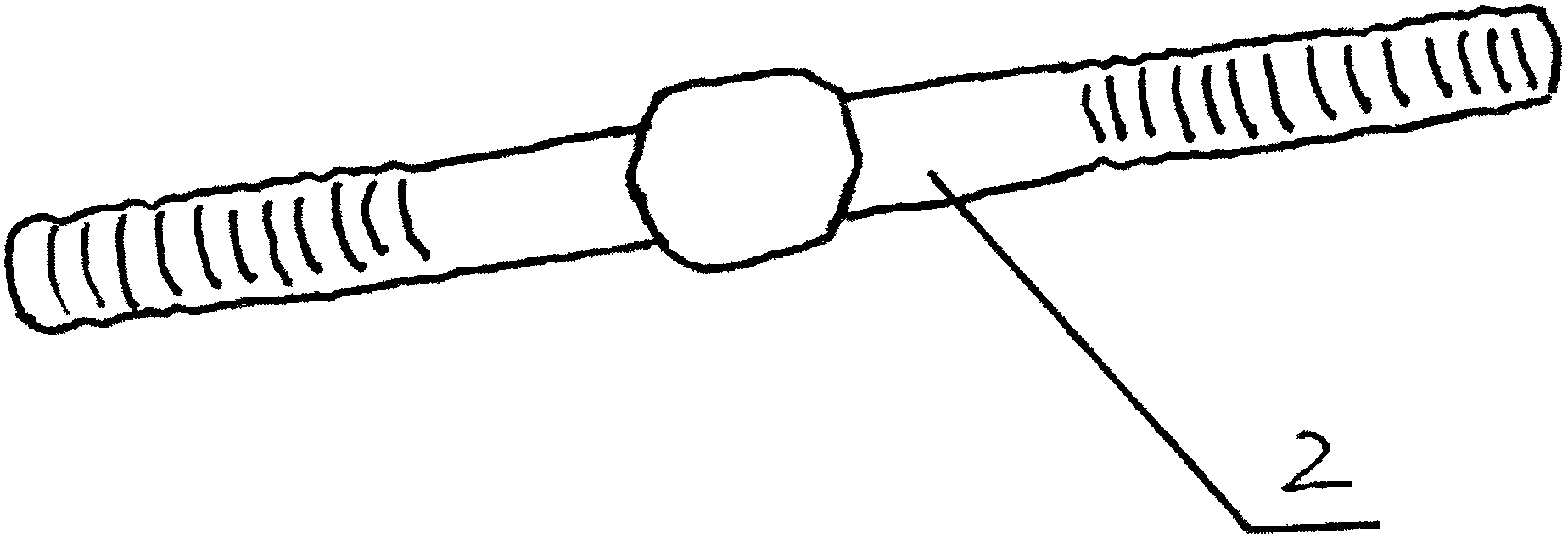

[0020] The present invention is composed of a collar (1) and positive and negative tension screw rods (2); wherein, the two ends of the positive and negative tension screw rods (2) are respectively twisted into the nuts arranged at both ends of the collar (1).

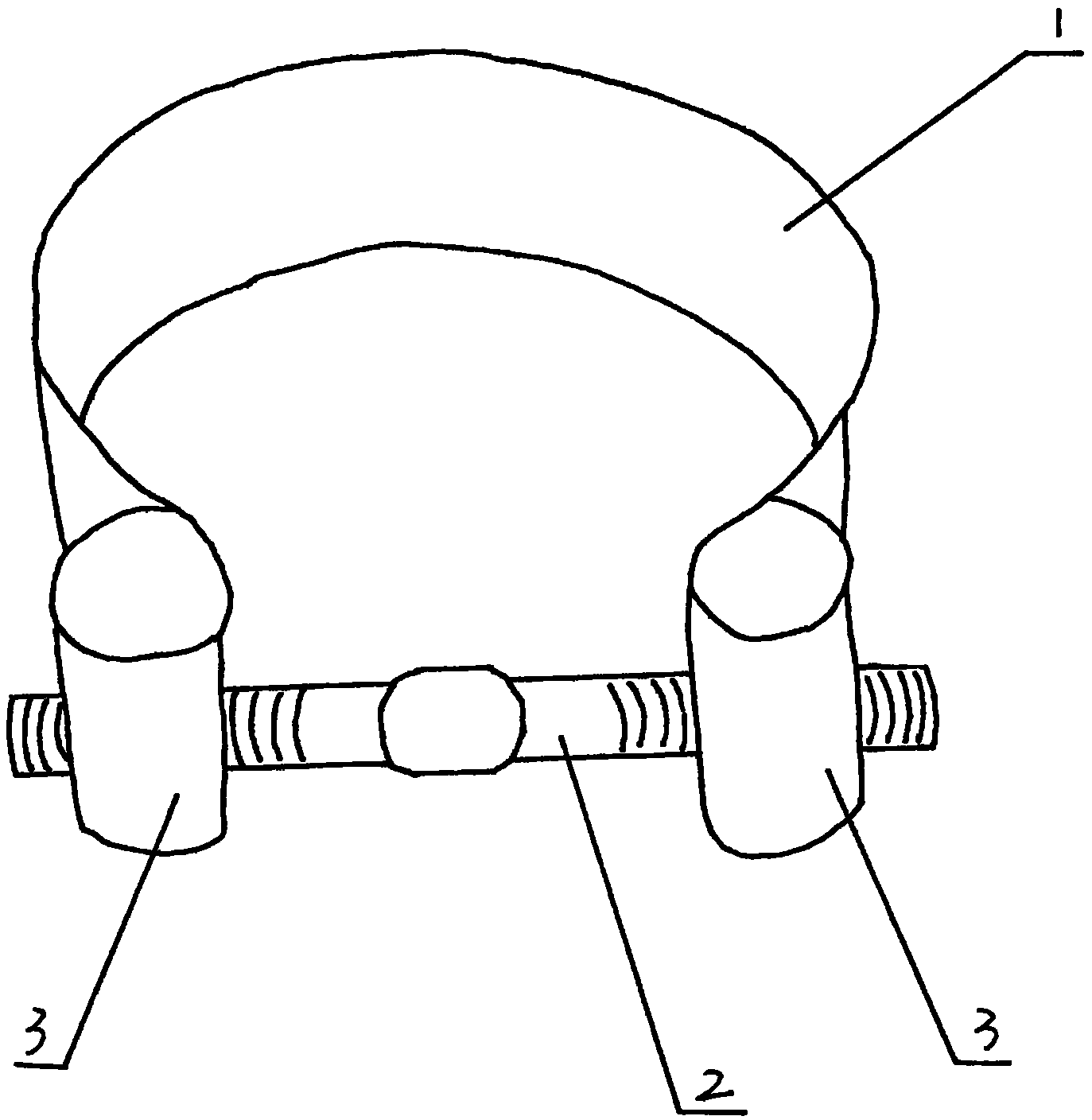

[0021] figure 1 shown. 1 is a collar (1), 2 is a tension screw rod (2) with positive and negative teeth, and 3 is a nut frame (3) that is respectively provided with at both ends of the collar.

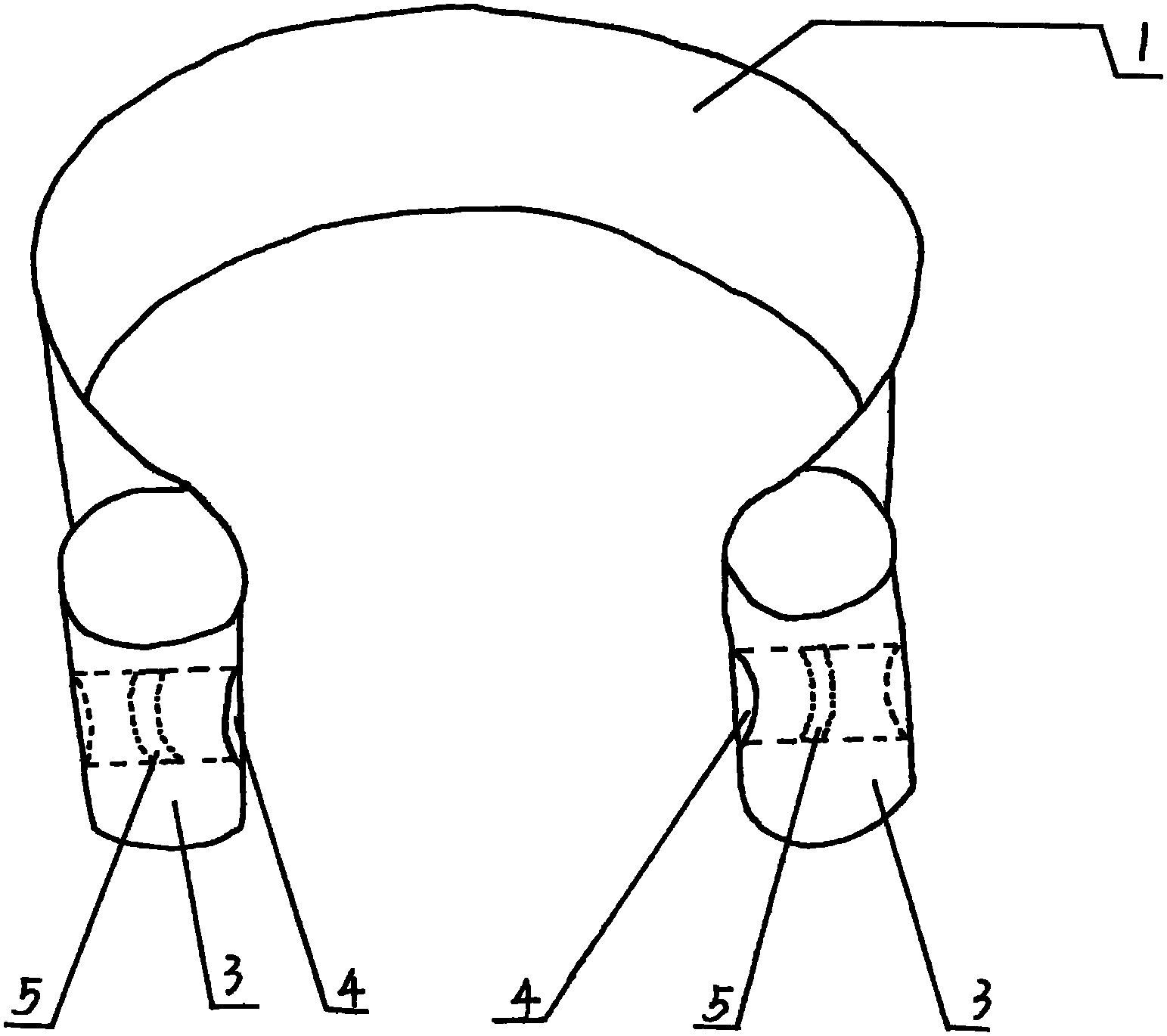

[0022] figure 2 shown. The structure of the collar (1) is a circular buckle, nut holders (3) are respectively arranged at the head and tail of both sides of the collar (1), and screw rods are respectively arranged in the middle of the nut holders (3) on both sides Holes (4), and nuts (5) are respectively arranged in the screw rod holes (4) on both sides.

[0023] image 3 shown. The positive and negative teeth tension sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com