Elastomeric silicone emulsion for coating applications

A technology of elastomers and coatings, applied in polyether coatings, coatings, etc., can solve the problems of poor anti-graffiti materials and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

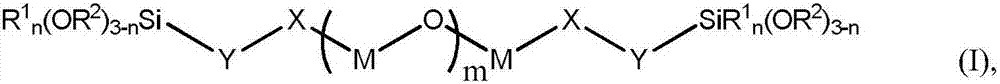

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

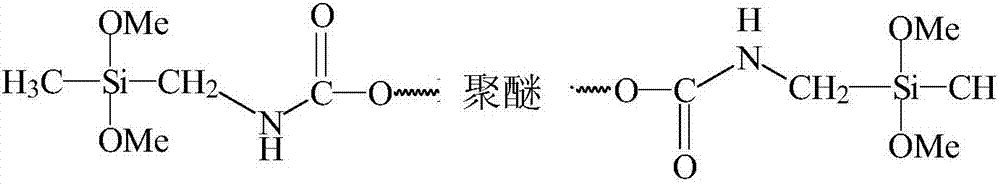

[0109] Embodiment 1: the preparation of the polyether emulsion of dimethoxy (methyl) silyl methyl carbamate termination

[0110] Emulsions were prepared according to the following method using the following compositions and weight percentages.

[0111]

[0112] The emulsion in Example 1 was prepared by the following steps:

[0113] Emulsifier ethoxylated isotridecyl alcohol and premixed water in Mix on mixer until foamy egg icing forms. The dimethoxymethylsilylmethylcarbamate terminated polyether was added to the egg icing and mixed for 4 minutes at 10000 rpm. Add deionized water and stir for 1 min at 5000 rpm. Additional deionized water was added and stirred at 5000 rpm for 1 minute, followed by additional deionized water at 5000 rpm for 1 minute.

[0114] The tensile strength and elongation of the emulsion of Example 1 were measured according to the ASTM D 2370 standard reference method using a 75mm x 13mm specimen shape; the crosshead spacing was set at 2.54cm (1.0 ...

Embodiment 2

[0115] Example 2: Preparation of an emulsion from a mixture of a dimethoxymethylsilylmethylcarbamate terminated polyether and a methoxyfunctional methylphenylpolysiloxane

[0116] Emulsions were prepared according to the method described in Example 1 using the combinations and weight percentages in the table below. Preparation of pre-blend polymers of dimethoxymethylsilylmethylcarbamate-terminated polyether and methoxy-functional methylphenylpolysiloxane in place of dimethoxymethylsilyl alone Methyl carbamate terminated polyether.

[0117]

[0118] The tensile strength and elongation of the emulsion of Example 2 are measured with a 75mm x 13mm sample shape according to the method referenced in the ASTM D 2370 standard; the chuck spacing is set to 2.54cm (1.0inch), and the crosshead speed is set to 0.042 cm / s (1 inch / min). The tensile strength of the emulsion of Example 2 is 186.158kPa (27psi), and the elongation is 172%.

[0119] Using another emulsifier such as ethoxyla...

Embodiment 3-7

[0150] Examples 3-7: Preparation of Other Useful Exemplary Emulsions

[0151] Other useful exemplary emulsions of Examples 3-7 were prepared according to the method described above, using the following components and weight percentages:

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com