Stainless steel cleaner and stainless steel cleaning method

A cleaning agent, stainless steel technology, applied in the cleaning agent group and the field of cleaning stainless steel with this cleaning agent, can solve the problems of discontinuity, incompleteness, incomplete cleaning of stainless steel cleaning agent, etc., achieve high cleanliness requirements and good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

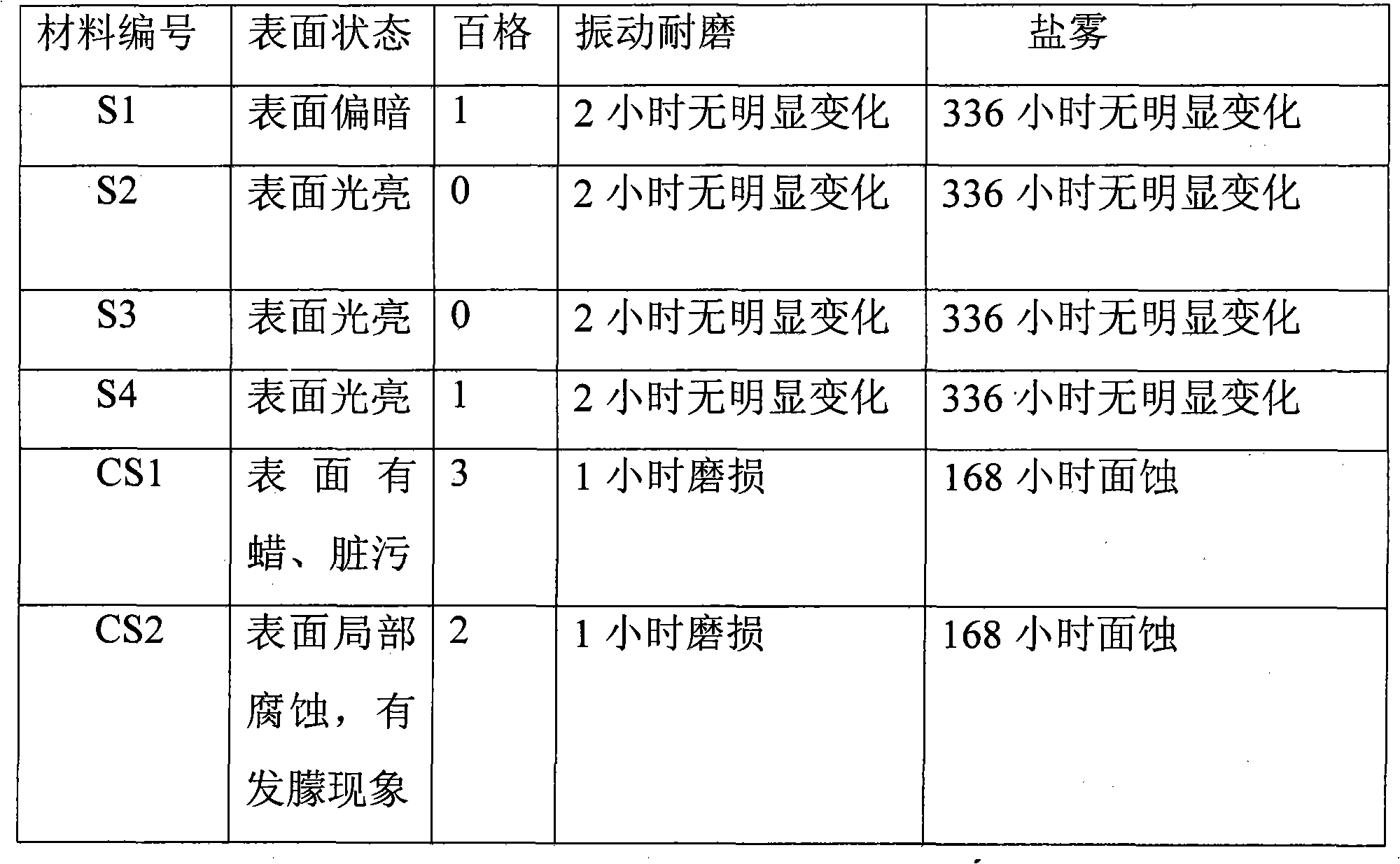

Examples

preparation example Construction

[0017] The preparation method of the cleaning agent of the present invention is as follows: after dissolving the cleaning agent in deionized water, the cleaning agent is continuously stirred for 1-2 hours under 50-1200 rpm magnetic or mechanical stirring. In order to avoid defects such as white spots or white spots that may be caused by uneven mixing of the cleaning agent, it is preferable to dissolve the components of the cleaning agent in deionized water and then mix them with each other.

[0018] The present invention also provides a stainless steel cleaning method, the method is ultrasonically cleaning the stainless steel workpiece in a cleaning agent, and the cleaning agent is the cleaning agent described in the present invention.

[0019] According to the stainless steel cleaning method provided by the present invention, preferably, the temperature of the ultrasonic cleaning is 70-90° C., and the ultrasonic time is 5-10 minutes. Ultrasonic vibration is used to remove oil...

Embodiment 1

[0028] This example illustrates the cleaning composition and cleaning method provided by the present invention.

[0029] (1) Detergent composition

[0030] In a flask with a stirring device, at a stirring speed of 1200 rpm, at room temperature, 5 grams of nonylphenol polyoxyethylene ether (Triton-100) (Shenzhen Chemical Test Technology Co., Ltd.), 5 grams of coconut acid diethanolamide (Shenzhen Chemical Test Technology Co., Ltd.), 5 grams of sodium dodecylbenzenesulfonate (Guangdong Dajinhua Chemical Factory Co., Ltd.), 10 grams of N, N-dimethylformamide, 20 grams of diethanolamine (Shenzhen Huashi Technology Co., Ltd.), 5 grams of disodium edetate, and finally 960 grams of deionized water were added and stirred continuously for 1.5 hours to obtain the cleaning agent A1 of the embodiment of the present invention.

[0031] (2) Cleaning method

[0032] A brushed stainless steel substrate (Wenzhou Jifeng Stainless Steel Co., Ltd.) with a size of 7.5 mm × 4.5 mm × 0.5 mm was co...

Embodiment 2

[0034] This example illustrates the cleaning composition and cleaning method provided by the present invention.

[0035] (1) Detergent composition

[0036] In a flask with a stirring device, at a stirring speed of 1000 rpm, at room temperature, 10 grams of sodium carbonate, 5 grams of trisodium citrate (Guangdong Guanghua Chemical Factory Co., Ltd.), 5 grams of nonylphenol polymer Oxyethylene ether (triton-100) (Shenzhen Chemical Test Technology Co., Ltd.), 5 grams of coconut acid diethanolamide (Shenzhen Chemical Test Technology Co., Ltd.), 5 grams of sodium dodecylbenzene sulfonate (Guangdong Dajinhua Chemical Factory Co., Ltd.), 10 grams of N, N-dimethylacetamide, 10 grams of triethanolamine (Shenzhen Chemical Test Technology Co., Ltd.), 950 grams of deionized water continued to stir for 1.5 hours to obtain the embodiment of the invention cleaning agent A2.

[0037] (2) Cleaning method

[0038] A brushed stainless steel substrate (Wenzhou Jifeng Stainless Steel Co., Ltd....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com