A liquid-filled forest fire extinguishing bomb for a transonic rifled gun

A transonic, fire-extinguishing bomb technology, used in warheads, ammunition, fire rescue, etc., can solve the problems of dry powder being easy to harden, and achieve the effects of low production cost, guaranteed drop point accuracy, and reduced safety radius.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

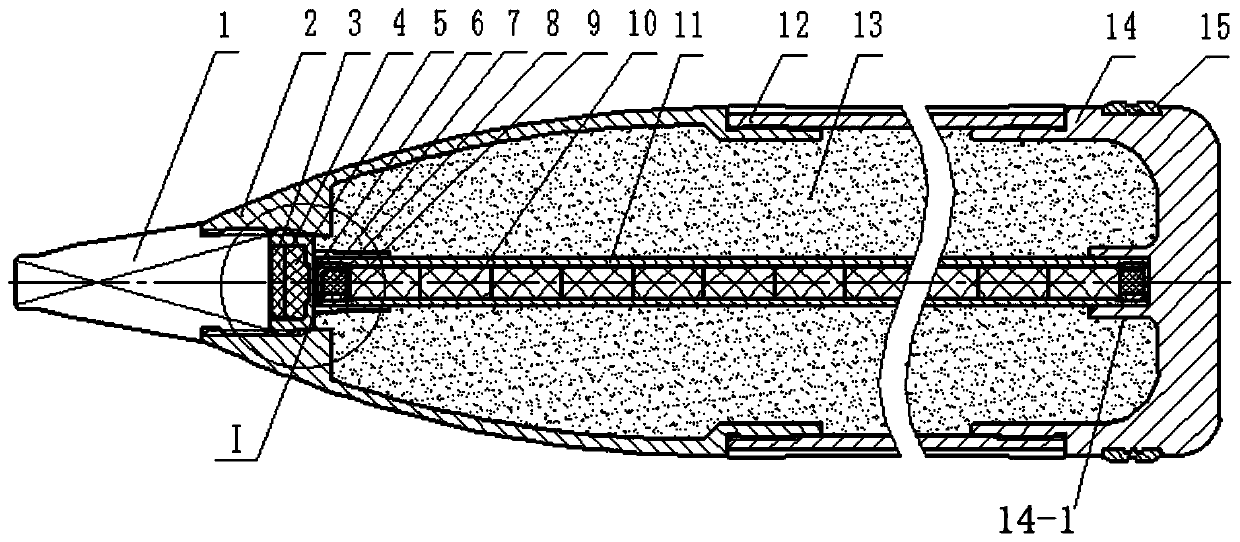

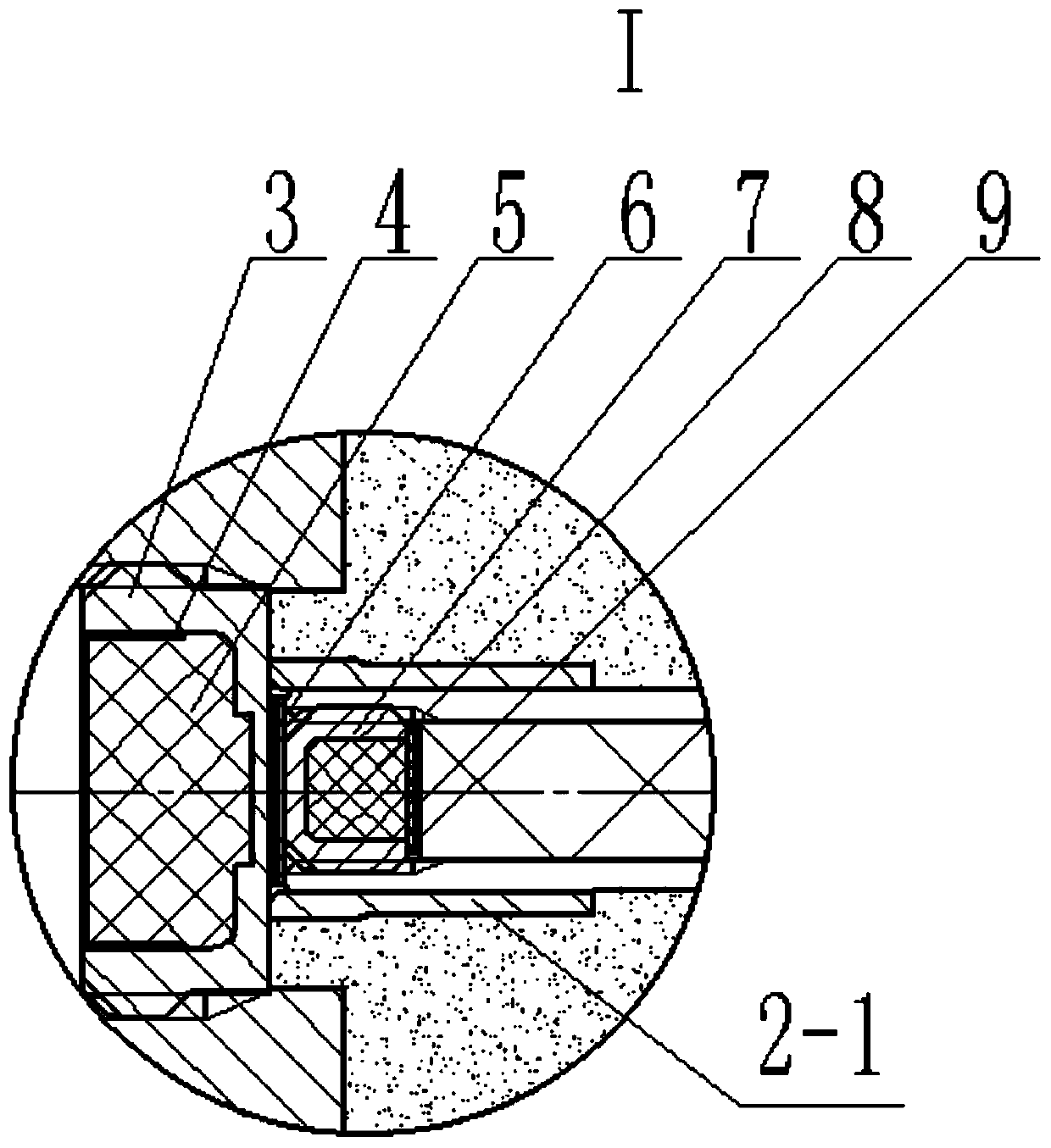

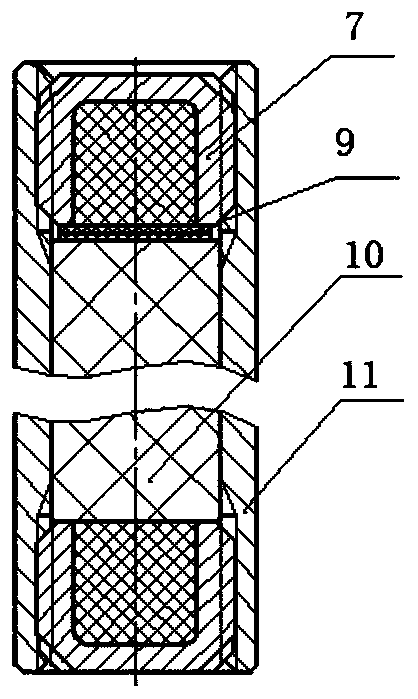

[0022] combine Figure 1-Figure 3 , a liquid-filled forest fire extinguishing bomb for a transonic rifled gun of the present invention, comprising a fuze 1, a head screw 2, a pressure screw 3, a reinforcing cap 4, an explosive expansion charge 5, a plastic gasket 6, a screw plug 7, a charge 8, a pad Sheet 9, powder column 10, drug tube 11, projectile body 12, liquid fire extinguishing agent 13, projectile bottom 14 and bullet belt 15 arranged outside the projectile bottom 14;

[0023] The fuze 1 is located at the front end of the whole fire extinguishing bomb, and is arranged on the front end of the head screw 2; the rear end of the head screw 2 is connected with the body 12; the rear end of the body 12 is connected with the bottom 14 of the bomb, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com