High antibacterial flame-retardant acrylonitrile-butadiene-styrene (ABS) material and preparation method thereof

A technology of ABS material and ABS resin, which is applied in the field of high antibacterial flame retardant ABS material and its preparation, can solve the problems of few antibacterial research reports on flame retardant ABS materials and reduce the antibacterial efficiency of materials, so as to avoid polymerization, prevent agglomeration, and prepare The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

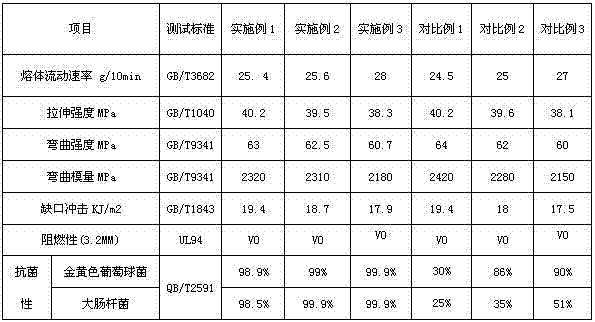

Examples

Embodiment 1

[0038] (1) Pre-disperse 3 parts of monoglyceride stearate and 0.1 part of zinc ion antibacterial agent in a high-speed mixer at 300 rpm for 3 minutes to obtain a diluted antibacterial agent premix with good dispersibility ;

[0039] (2) 50 parts of ABS resin, 10 parts of acrylic toughener, 15 parts of bromotriazine, 4 parts of antimony trioxide, 0.2 parts of polytetrafluoroethylene, 0.5 parts of zinc stearate, 0.3 parts of antioxidant 1010. Add 0.5 parts of lubricant silicone oil to the mixer in turn, and mix in the mixer at 200 rpm for 5 minutes; then add the dispersed antibacterial agent premix in (1) and stir at a low speed of 200 rpm for 10 minutes, to obtain a homogeneous mixture;

[0040] (3) Put the mixture of (2) into a twin-screw extruder, melt, extrude, water-cool, air-dry, and cut to obtain a high antibacterial and flame-retardant ABS material.

[0041]

Embodiment 2

[0043] (1) Pre-disperse 4 parts of monoglyceride stearate and 0.5 part of zinc ion antibacterial agent in a high-speed mixer at 400 rpm for 2 minutes to obtain a diluted antibacterial agent premix with good dispersibility ;

[0044] (2) 60 parts of ABS resin, 7 parts of toughening agent styrene-butadiene thermoplastic elastomer, 18 parts of tetrabromobisphenol A, 5 parts of antimony pentoxide, 0.2 parts of polytetrafluoroethylene, 1 part of stearin Calcium acid calcium, 0.2 parts of antioxidant 1010, 0.3 parts of antioxidant 1076 antioxidant, 0.5 parts of pentaerythritol stearate were added to the mixer in sequence, and mixed in the mixer at 300 rpm for 4 minutes; then added to (1) The dispersed antibacterial agent premix was stirred at a low speed of 150 rpm for 5 minutes to obtain a homogeneous mixture;

[0045] (3) Put the mixture of (2) into a twin-screw extruder, melt, extrude, water-cool, air-dry, and cut to obtain a high antibacterial and flame-retardant ABS material. ...

Embodiment 3

[0048] (1) Pre-disperse 5 parts of monoglyceride stearate and 1.5 parts of zinc ion antibacterial agent in a high-speed mixer at 500 rpm for 1 minute to obtain a diluted antibacterial agent premix with good dispersibility ;

[0049] (2) 80 parts of ABS resin, 10 parts of acrylonitrile-butadiene-styrene copolymer (ABS), 10 parts of brominated epoxy, 10 parts of brominated triazine, 1 part of zinc borate, 0.5 parts of polytetrafluoroethylene Ethylene, 0.5 parts of calcium stearate, 0.5 parts of magnesium stearate, 0.5 parts of antioxidant 245, and 1.2 parts of ethylene bis stearic acid amide are added to the mixer in turn, and mixed for 3 minutes in a mixer at 400 rpm; then Add the antimicrobial agent premix dispersed in (1) and stir at a low speed of 100 rpm for 10 minutes to obtain a well-mixed mixture;

[0050] (3) Put the mixture of (2) into a twin-screw extruder, melt, extrude, water-cool, air-dry, and cut to obtain a high antibacterial and flame-retardant ABS material.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com