Efficient flame retardant polyolefin composition

A polyolefin and composition technology, which is applied in the field of high-efficiency flame-retardant polyolefin compositions, can solve the problems of high cost, flame-retardant failure, low thermal decomposition temperature, etc., and achieves high flame-retardant synergy and efficient flame-retardant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

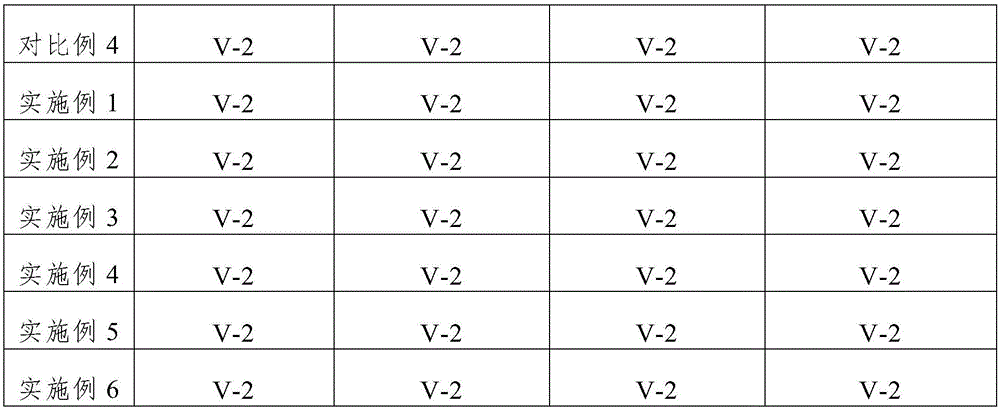

Embodiment 1

[0026] The flame-retardant polyolefin composition of this embodiment is made of the following mass percentages of raw materials: polypropylene 97.5%, hypophosphite 1%, melamine hydrobromide 0.5%, flame retardant synergist 0.5%, lubricant EBS0. 2%, 0.1% of main antioxidant, 1680.2% of auxiliary antioxidant. The hypophosphite is aluminum hypophosphite, the main antioxidant is antioxidant 1010, the auxiliary antioxidant is antioxidant 168, and the flame retardant synergist is cumene and p-diiso The polymerization mixture generated by the polymerization reaction of propylbenzene, the preparation method of the polymerization mixture includes the following steps:

[0027] Step 1. Put cumene and p-diisopropylbenzene into a three-necked flask, stir under the protection of a nitrogen atmosphere and raise the temperature to 130°C, and then drop di-tert-butyl peroxide at a rate of 0.75mL / min The polymerization reaction is carried out in the heated mixture of cumene and p-diisopropylbenzene...

Embodiment 2

[0044] The flame-retardant polyolefin composition of this embodiment is made of the following mass percentages of raw materials: polypropylene 98.4%, hypophosphite 0.4%, melamine hydrobromide 0.4%, flame retardant synergist 0.5%, lubricant EBS0. 1%, 0.1% of main antioxidant, 0.1% of auxiliary antioxidant. The hypophosphite is magnesium hypophosphite, the main antioxidant is antioxidant 1010, the auxiliary antioxidant is antioxidant 168, and the flame retardant synergist is 4-methyl cumene The polymerization mixture produced by the polymerization reaction with p-diisopropylbenzene, the preparation method of the polymerization mixture includes the following steps:

[0045] Step 1. Add 4-methylisopropylbenzene and p-diisopropylbenzene into a three-necked flask, stir under the protection of a nitrogen atmosphere and raise the temperature to 90°C, and then peroxidize tert-butyl at a rate of 1.5mL / min Hydrogen was dropped into the heated mixture of 4-methylisopropylbenzene and p-diiso...

Embodiment 3

[0049] The flame-retardant polyolefin composition of this embodiment is made of the following mass percentages of raw materials: 95.6% of polypropylene, 1.2% of hypophosphite, 0.8% of melamine hydrobromide, 1.5% of flame retardant synergist, and lubricant EBS0. 3%, main antioxidant 0.3%, auxiliary antioxidant 0.3%. The hypophosphite is calcium hypophosphite. The main antioxidant is antioxidant 1010, the auxiliary antioxidant is antioxidant 168, and the flame-retardant synergist is the polymerization reaction of 3-methyl cumene and p-diisopropyl benzene. The resulting polymerization mixture, the preparation method of the polymerization mixture includes the following steps:

[0050] Step 1. Add 3-methylisopropylbenzene and p-diisopropylbenzene into a three-necked flask, stir under the protection of a nitrogen atmosphere and raise the temperature to 120℃, and then oxidize the di-tert-butylperoxide at a rate of 1mL / min The substance was dropped into the heated mixture of 3-methylis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com