High-fluidity high-fire resistance polyvinyl chloride composite material and method for preparing same

A technology of polyvinyl chloride and composite materials, applied in the field of soft polyvinyl chloride composite materials and their preparation, polyvinyl chloride composite materials and their preparation, can solve the problems of poor flame retardancy, reduced flame retardancy, instability, etc. Achieve the effects of good fluidity and flame retardancy, easy processing, and increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Raw material formula component and parts by weight thereof are as follows:

[0040] PVC: 100 parts

[0041] Stabilizer: 3 parts

[0042] Lubricant: 2 parts

[0043] Plasticizer: 40 parts

[0044] Antioxidant: 0.3 parts

[0045] Anti-ultraviolet agent: 0.3 parts

[0046] Brominated flame retardant: 6 parts

[0047] Antimony trioxide: 4 parts

[0048] Zinc borate: 6 parts

[0049] Vinyl chloride copolymer resin: 15 parts

[0050] Above-mentioned polyvinyl chloride composite material raw material is prepared by following method:

[0051] Ingredients: Weigh polyvinyl chloride, stabilizer, lubricant and plasticizer respectively according to parts by weight.

[0052] Mixing: Stir the above ingredients in a high-speed mixer to about 115 degrees, and the mixing process is suspended.

[0053] Adding and high mixing: add the remaining ingredients in the formula, mix at high speed for 1 to 5 minutes, enter the cold mixer to cool to about 45 degrees, then discharge, and c...

Embodiment 2

[0057] Raw material formula component and parts by weight thereof are as follows:

[0058] PVC: 100 parts

[0059] Stabilizer: 4 parts

[0060] Lubricant: 3 parts

[0061] Plasticizer: 45 parts

[0062] Antioxidant: 0.4 parts

[0063] Anti-ultraviolet agent: 0.4 parts

[0064] Brominated flame retardant: 8 parts

[0065] Antimony trioxide: 6 parts

[0066] Zinc borate: 8 parts

[0067] Vinyl chloride copolymer resin: 18 parts

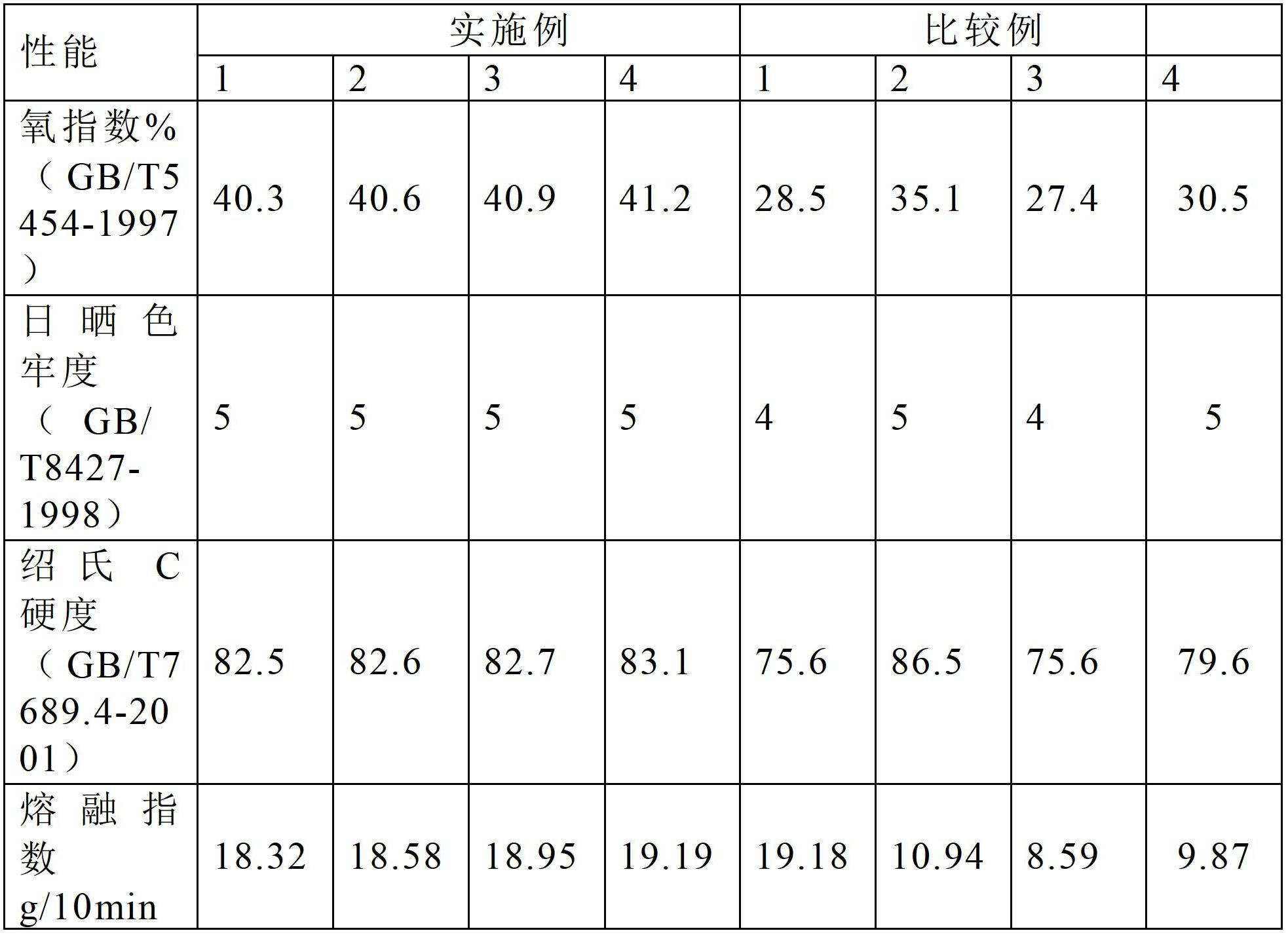

[0068] The preparation method of the raw material of the polyvinyl chloride composite material is the same as that of Example 1, and the main physical properties of the prepared polyvinyl chloride composite material are shown in Table 1.

Embodiment 3

[0070] Raw material formula component and parts by weight thereof are as follows:

[0071] PVC: 100 parts

[0072] Stabilizer: 5 parts

[0073] Lubricant: 5 parts

[0074] Plasticizer: 48 parts

[0075] Antioxidant: 0.5 parts

[0076] Anti-ultraviolet agent: 0.4 parts

[0077] Brominated flame retardant: 10 parts

[0078] Antimony trioxide: 6 parts

[0079] Zinc borate: 10 parts

[0080] Vinyl chloride copolymer resin: 22 parts

[0081] The preparation method of the raw material of the polyvinyl chloride composite material is the same as that of Example 1, and the main physical properties of the prepared polyvinyl chloride composite material are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com