Water-based flame-retardant coating adhesive and preparation method thereof

A flame-retardant coating and water-based technology, which is applied in the field of water-based flame-retardant coating adhesive for textiles and its preparation, can solve the problems of difficulty in passing, unable to form an expanded carbon layer, and the carbon layer is not continuous enough, and achieves broad market prospects , excellent flame retardant properties, improve the effect of hydrostatic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

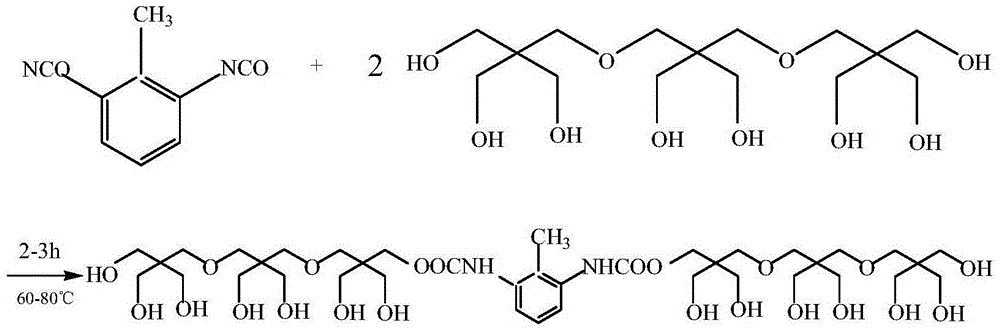

[0024] Example 1-3: Synthesis of polyols

Embodiment 1

[0026] Toluene diisocyanate: 174g (1mol)

[0027] Tripentaerythritol: 559g (1.5mol)

[0028] Butanone: 200-300g

[0029] Add 559g of tripentaerythritol into a four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, start stirring, add an appropriate amount of butanone, and stir evenly, then add 174g of toluene diisocyanate into the four-necked flask, and slowly heat up to 70°C The reaction was carried out for 2-3 hours until the NCO content reached the theoretical value (detected by di-n-butylamine titration method), the butanone was removed and dried to obtain a polyhydroxy compound.

Embodiment 2

[0031] Isophorone diisocyanate: 222g (1mol)

[0032] Tripentaerythritol: 596g (1.6mol)

[0033] Butanone: 200-300g

[0034] Add 596g of tripentaerythritol into a four-necked flask equipped with a stirrer, a reflux condenser, and a thermometer, start stirring, add an appropriate amount of butanone, and after stirring evenly, add 222g of isophorone diisocyanate into the four-necked flask, and slowly heat up React at 75°C for 2-3h, until the NCO content reaches the theoretical value (detect it with di-n-butylamine titration method), remove methyl ethyl ketone, and dry to obtain a polyhydroxy compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com