Waterborne flame-retardant polyurethane resin and preparation method thereof

A technology of polyurethane resin and polyurethane, which is applied in the field of water-based polyurethane resin and its preparation, can solve the problems that polyurethane resin has no flame retardancy, affects product performance, and reduces flame retardancy, and achieves good flame retardancy, excellent flame retardancy, and good The effect of binding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

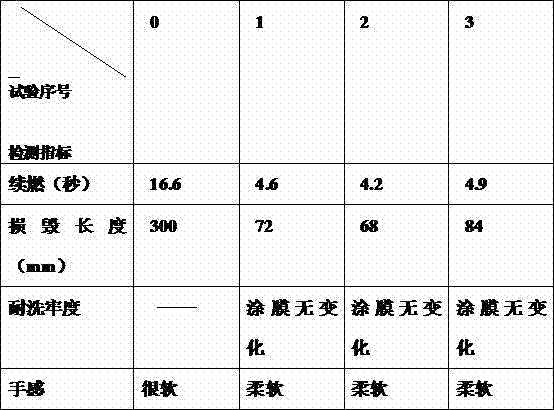

Examples

Embodiment 1

[0029] Preparation of polyurethane prepolymer A containing bromine flame-retardant polyether:

[0030] Flame retardant polyether polyol (IXOLB125), hydroxyl value 239mgKOH / g, bromine content 32%, 110g

[0031] Polyoxypropylene ether glycol, molecular weight 2000, 60g

[0032] Dimethylolpropionic acid 6g

[0033] 1.6-Hexane diisocyanate (HDI) 70g

[0034] N-methylpyrrolidone 60g

[0035] Dibutyltin dilaurate 0.05g

[0036] Add a four-necked flask equipped with a reflux condenser, a thermometer, and a stirrer in sequence. The reaction temperature is 80° C., and the reaction time is 5 hours to prepare polyurethane prepolymer A;

[0037] Preparation of blocked isocyanate polyurethane B containing bromine flame-retardant polyether:

[0038] Flame retardant polyether polyol (IXOLB125), hydroxyl value 239mgKOH / g, bromine content 32%, 160g

[0039] Polyoxyethylene ether glycol, molecular weight 2000, 80g

[0040] Isophorone diisocyanate (IPDI) 115g

[0041] N-methylpyrrolidone 60g

[0042] Dibutyltin d...

Embodiment 2

[0047] Preparation of polyurethane prepolymer A containing bromine flame-retardant polyether:

[0048] Flame retardant polyether polyol (IXOLB125), hydroxyl value 239mgKOH / g, bromine content 32%, 100g

[0049] Polyoxypropylene ether glycol, molecular weight 2000, 60g

[0050] Dimethylolpropionic acid 8g

[0051] Toluene diisocyanate (TDI) 73.6g

[0053] Catalyst dibutyl tin dilaurate 0.05g

[0054] A four-necked flask equipped with a reflux condenser, a thermometer, and a stirrer was sequentially added, the reaction temperature was 80° C., and the reaction time was 5 hours, to obtain a polyurethane prepolymer A.

[0055] Preparation of blocked isocyanate polyurethane B containing bromine flame-retardant polyether:

[0056] Flame retardant polyether polyol (IXOLB125) hydroxyl value 239mgKOH / g, bromine content 32%, 180g

[0057] Polyoxyethylene ether glycol, molecular weight 2500, 80g

[0058] Toluene diisocyanate (TDI) 108g

[0059] Acetone 60g

[0060] Catalyst dibu...

Embodiment 3

[0065] Preparation of polyurethane prepolymer A containing bromine flame-retardant polyether:

[0066] Flame-retardant polyether polyol (IXOLB125), hydroxyl value 239mgKOH / g, bromine content 32%, 80g

[0067] Polyoxypropylene ether glycol, molecular weight 3000, 56g

[0068] Dihydroxymethyl butyric acid 5.6g

[0069] Dicyclohexylmethane diisocyanate (H 12 MDI) 89g

[0070] Solvent dioxane 60g

[0071] Catalyst dibutyl tin acetate 0.05g

[0072] A four-necked flask equipped with a reflux condenser, a thermometer, and a stirrer was sequentially added, the reaction temperature was 80° C., and the reaction time was 5 hours, to obtain a polyurethane prepolymer A.

[0073] Preparation of blocked isocyanate polyurethane B containing bromine flame-retardant polyether:

[0074] Flame retardant polyether polyol (IXOLB125), hydroxyl value 239mgKOH / g, bromine content 32%, 150g

[0075] Polyoxyethylene ether glycol, molecular weight 2500, 66g

[0076] 1.6-Hexane diisocyanate (HDI) 87g

[0077] Solvent diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com