Flame-retardant polymer modified asphalt waterproof roll and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the direction of asphalt layered products, chemical instruments and methods, synthetic resin layered products, etc., can solve the harm of flame retardants to human body and environment, and has not formulated a unified flame retardant asphalt material test Standards and other issues, to achieve the effect of good construction performance, excellent high and low temperature resistance performance, and large elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

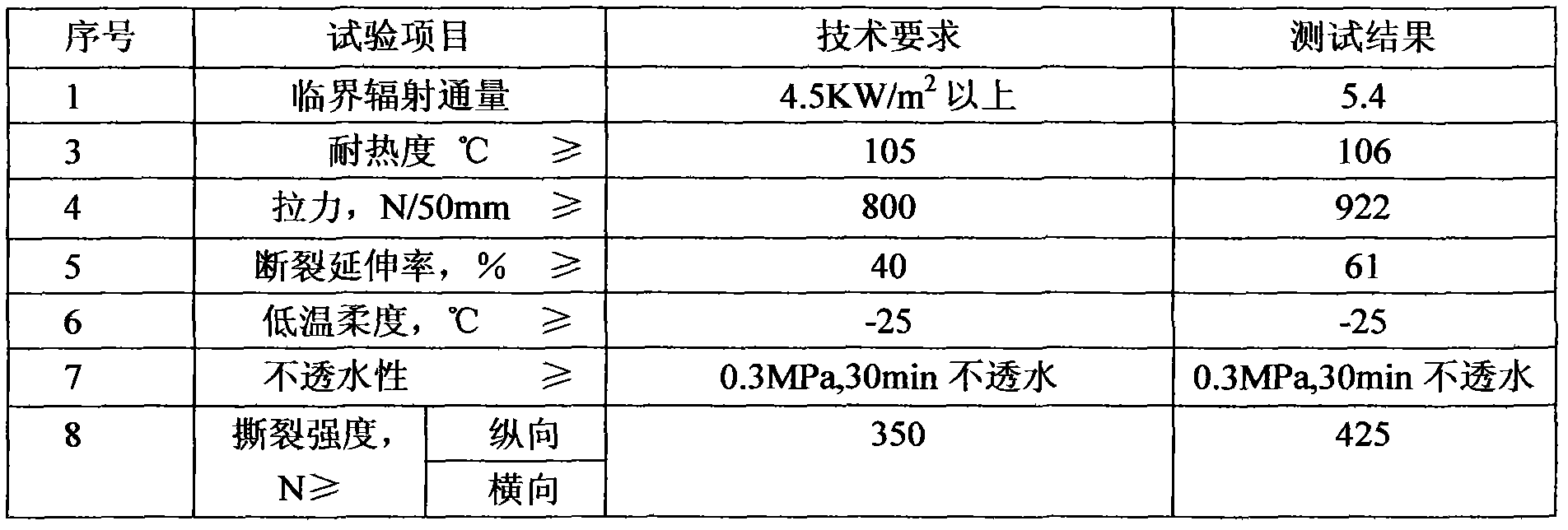

Embodiment 1

[0038] The proportioning by weight is as follows: 100 parts of heavy traffic road petroleum asphalt, 3 parts of decabromodiphenylethane, 7 parts of antimony trioxide, 3 parts of magnesium hydroxide, 4 parts of aluminum hydroxide, 3 parts of zinc borate, butyl 15 parts of diene-styrene-butadiene copolymer, 2 parts of styrene-butadiene rubber, 3 parts of atactic polypropylene, and accurately weighed asphalt, polymer modifier, and composite flame-retardant The agent is stirred to achieve macroscopic uniformity, and the flame-retardant polymer-modified asphalt waterproof membrane is obtained through the membrane forming process. The performance test was carried out according to the national standard GB18242-2008 "Elastomer Modified Bituminous Waterproof Membrane". The flame retardant performance was tested according to GB / T 11785-2005 "Determination of Combustion Performance of Flooring Materials". The test results are shown in Table 1.

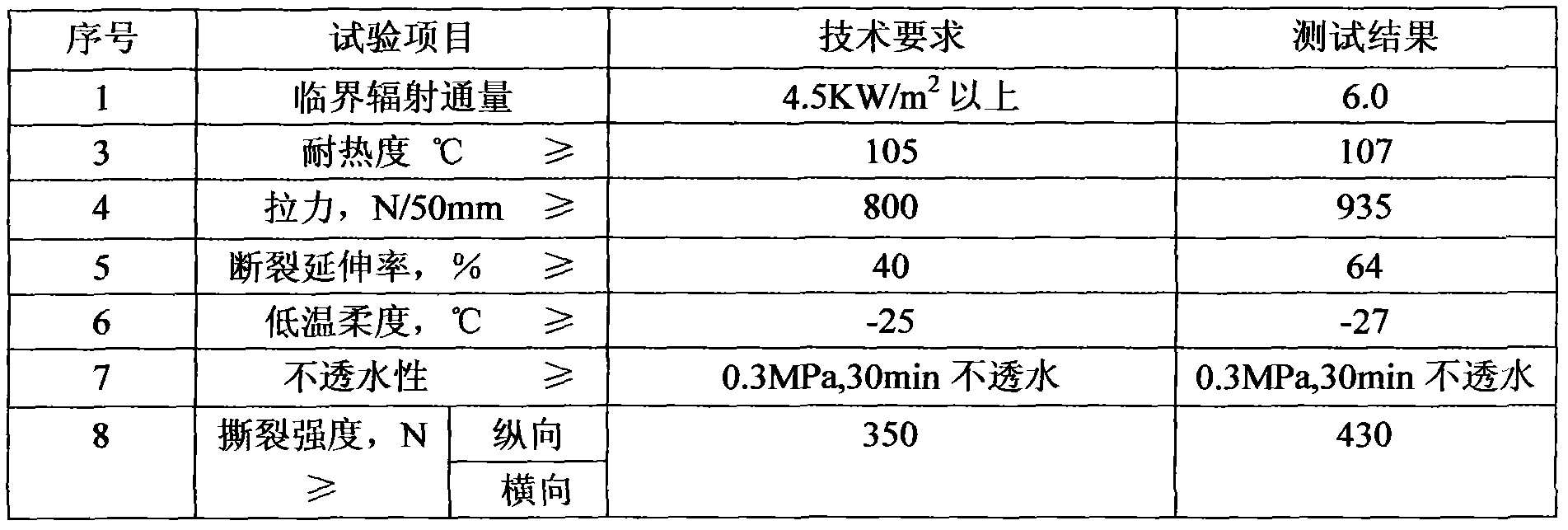

Embodiment 2

[0040] The ratio by weight percentage is as follows: 100 parts of heavy traffic road petroleum asphalt, 7 parts of decabromodiphenylethane, 10 parts of antimony trioxide, 3 parts of magnesium hydroxide, 3 parts of aluminum hydroxide, 2 parts of zinc borate, butane 18 parts of ethylene-styrene-butadiene copolymer, 3 parts of styrene-butadiene rubber, and 4 parts of random polypropylene, and the accurately weighed asphalt, composite flame retardant, and polymer modifier are added in sequence to the mixing equipment. Stir to achieve macroscopic uniformity, and obtain a flame-retardant polymer-modified asphalt waterproof membrane through a membrane forming process. The performance test was carried out according to the national standard GB18242-2008 "Elastomer Modified Bituminous Waterproof Membrane". The flame retardant performance was tested according to GB / T11785-2005 "Determination of Combustion Performance of Flooring Materials". The test results are shown in Table 2.

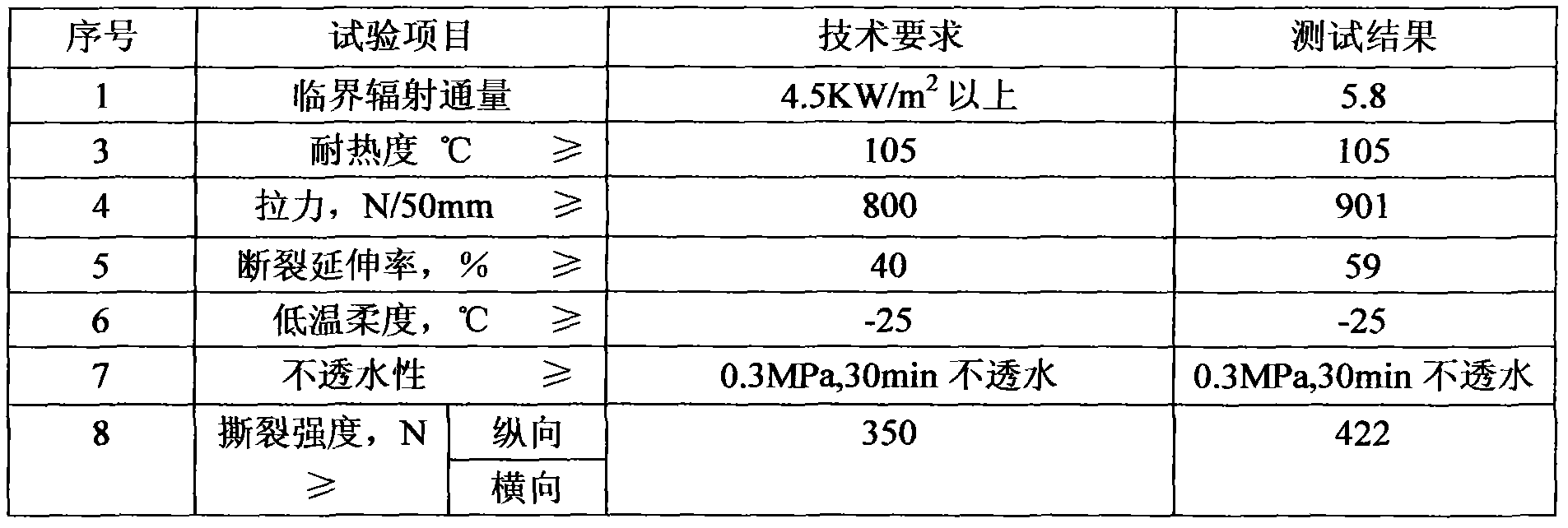

Embodiment 3

[0042] The ratio by weight percentage is as follows: 100 parts of heavy traffic road petroleum asphalt, 7 parts of decabromodiphenylethane, 10 parts of antimony trioxide, 5 parts of magnesium hydroxide, 4 parts of aluminum hydroxide, 1 part of zinc borate, polymer Modifier 27 20 parts of butadiene-styrene-butadiene copolymer, 4 parts of styrene-butadiene rubber, 3 parts of atactic polypropylene, and add accurately weighed asphalt and composite flame retardant in the mixing equipment in sequence , The polymer modifier is stirred to achieve macroscopic uniformity, and the flame-retardant polymer-modified bitumen waterproof membrane is obtained through the coil forming process. The performance test was carried out according to the national standard GB18242-2008 "Elastomer Modified Bitumen Waterproof Membrane". The flame retardant performance was tested according to GB / T 11785-2005 "Determination of Combustion Performance of Flooring Materials". The test results are shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com