Flame-retardant highly impact resistant polystyrene complex containing decabromodiphenylethane and preparation thereof

A technology of flame-retardant high-impact polystyrene and decabromodiphenylethane, which is applied in the field of flame-retardant high-impact polystyrene composites and its preparation, can solve problems such as restrictions on popularization and use, and achieve good mechanical properties, Easy to process and shape, optimize the effect of processing aid system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

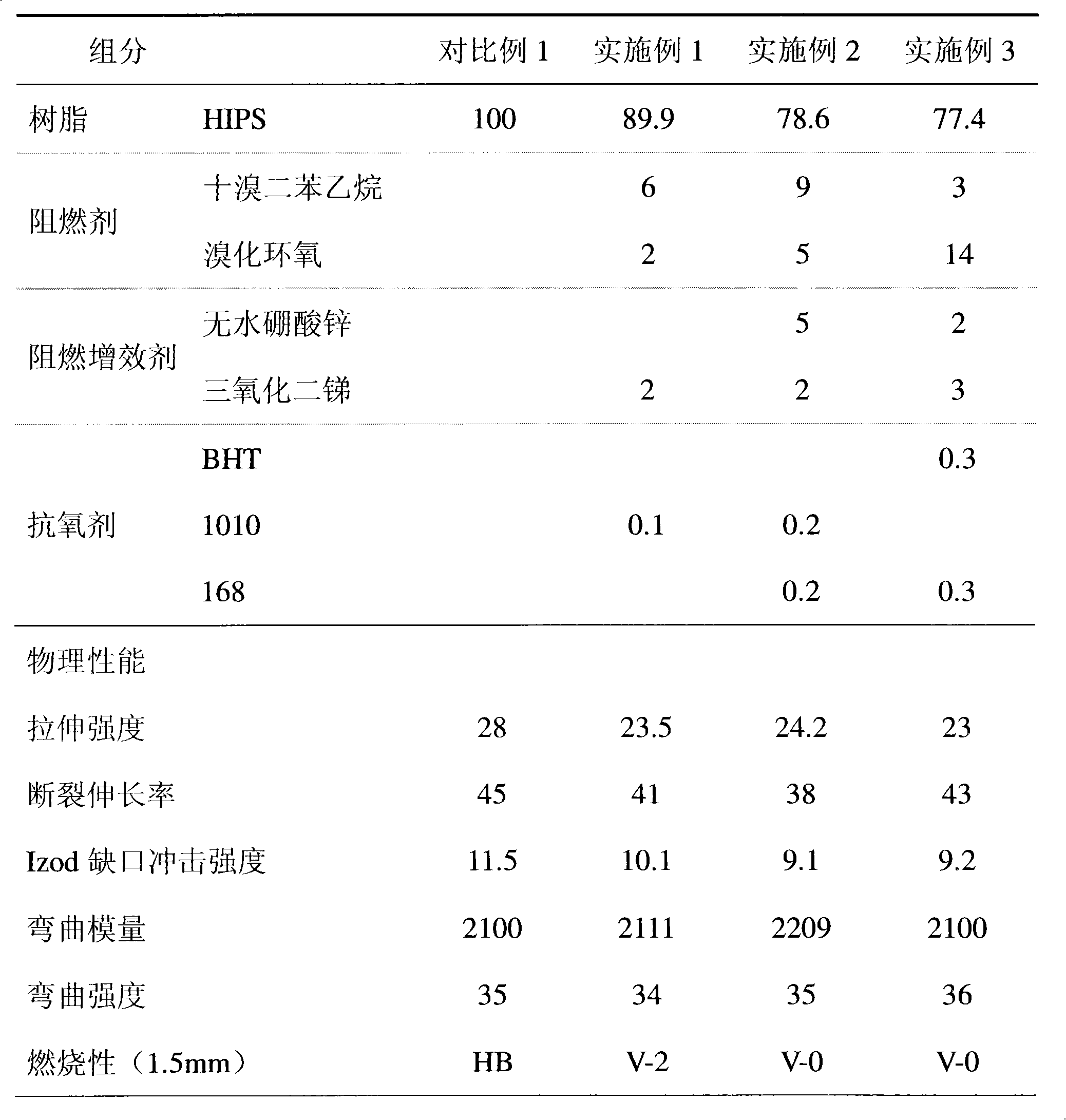

[0013] Preparation method: After fully mixing the components under high-speed stirring, melt, knead, extrude, cool, dry, pelletize and pack through a twin-screw extruder. The temperature of each partition of the screw barrel should be kept between 180 and 240 °C. The length-to-diameter ratio of the twin-screw extruder is 32-40, and the screw speed is 300-500 rpm.

[0014] This experiment uses HIPS with a butadiene rubber content of 3-10%, a mixture of decabromodiphenylethane and brominated epoxy or tetrabromobisphenol A as a flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com