Flame retardant polypropylene composite material and its preparation method

A composite material and polypropylene technology, applied in the field of flame retardant polypropylene composite material and its preparation, can solve the problems of carcinogenicity and limited application of composite materials, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] In addition, the present invention also provides a method for preparing a flame-retardant polypropylene composite material, comprising the following steps:

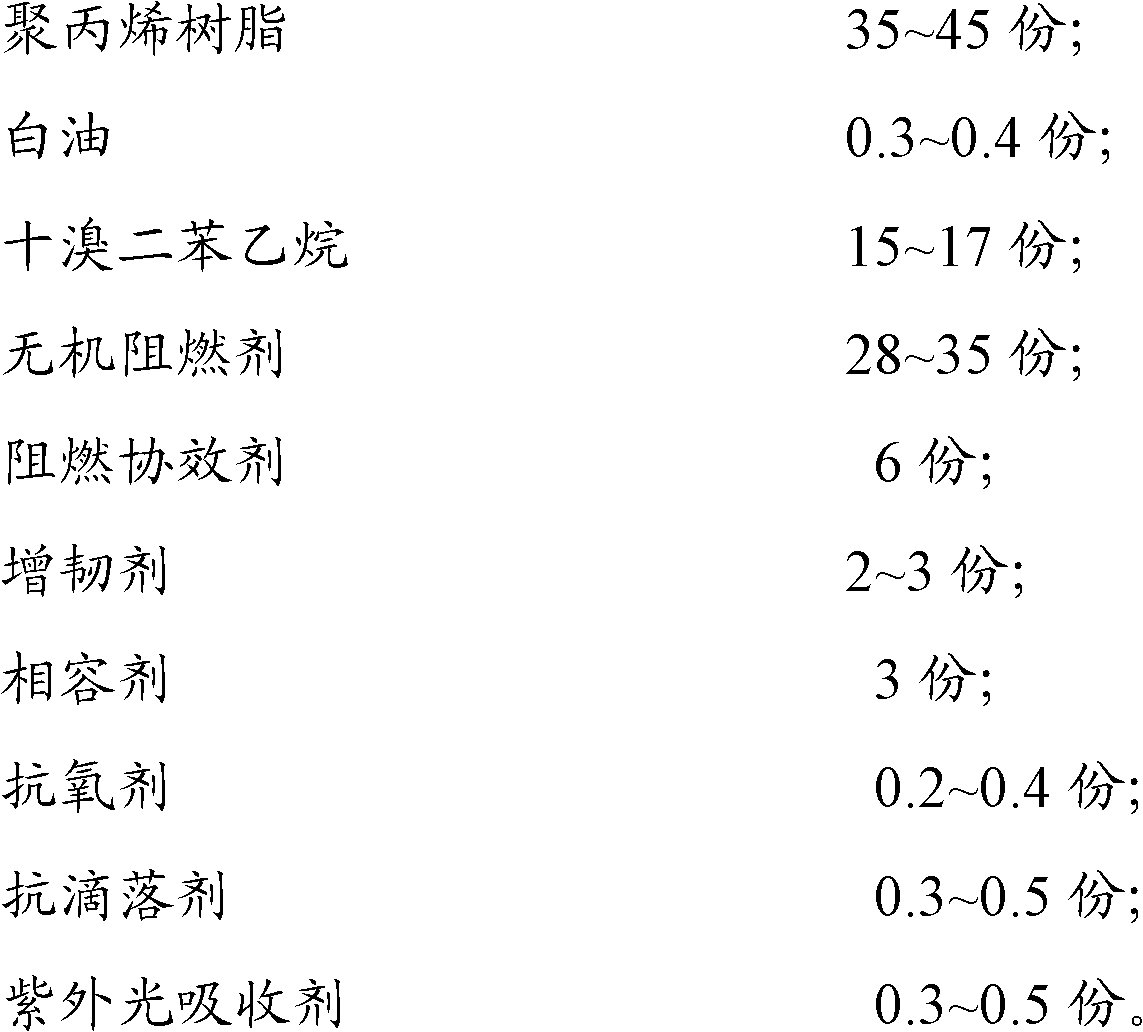

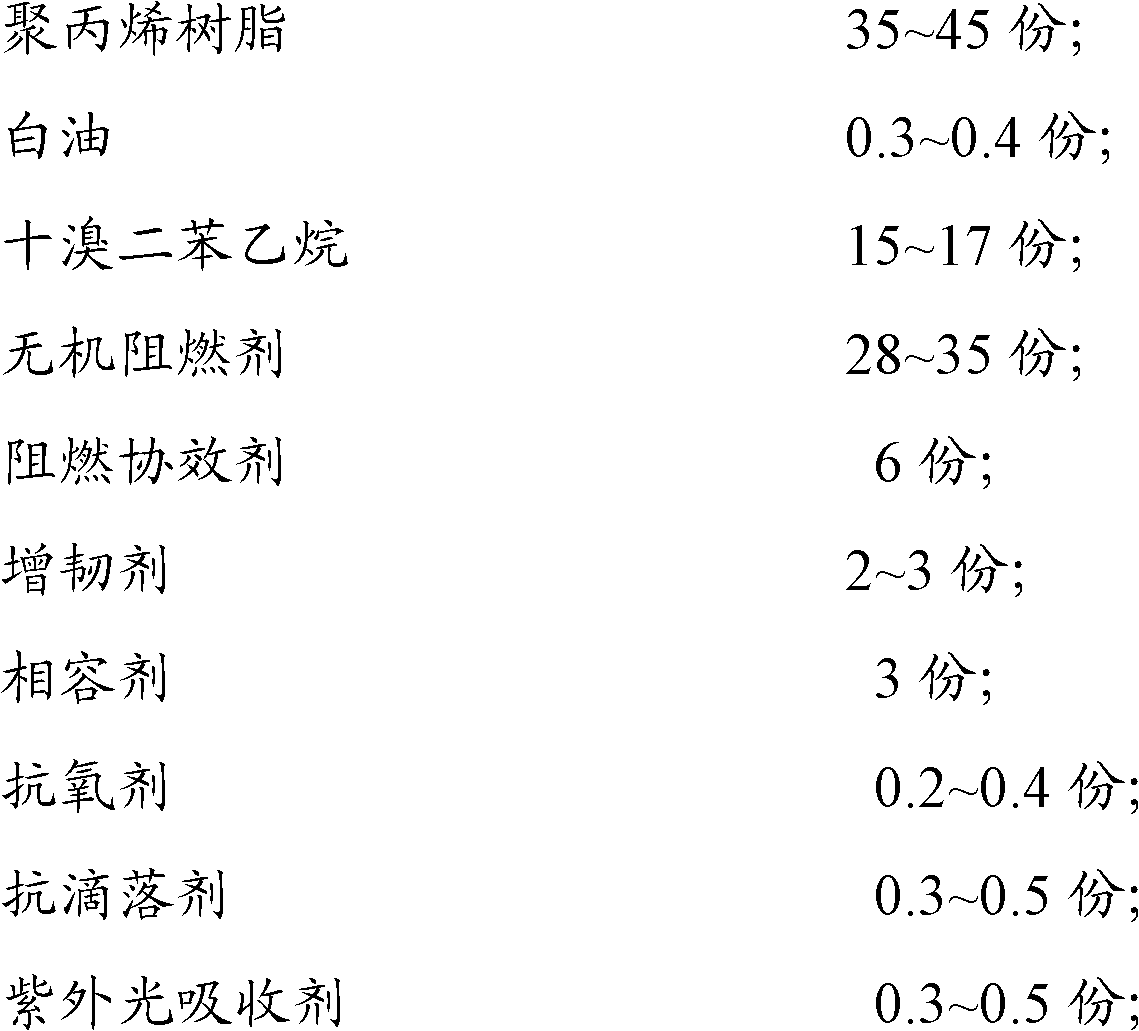

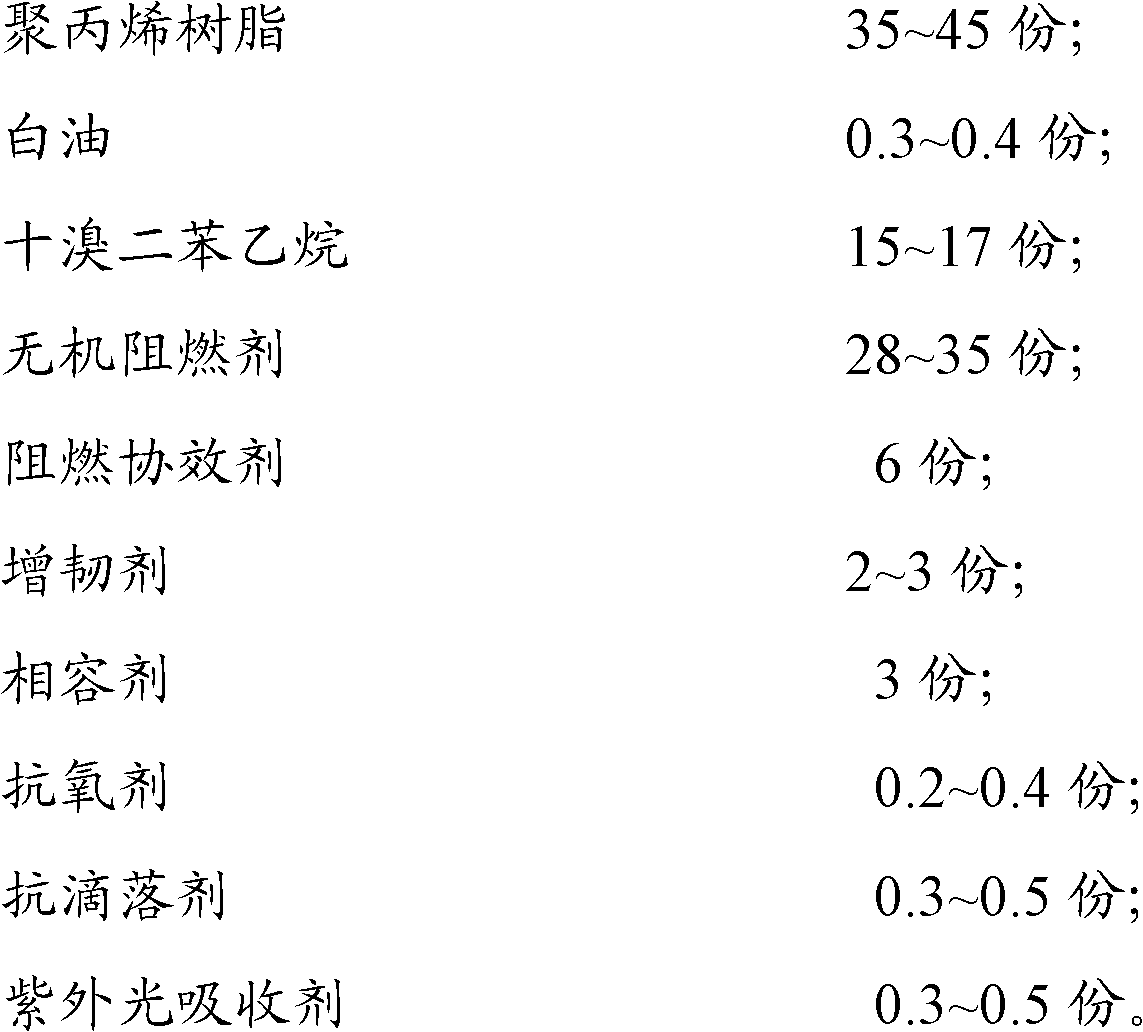

[0031] Take each raw material component by weight parts as follows:

[0032]

[0033] First, fully mix polypropylene resin, white oil, toughener and compatibilizer, then add decabromodiphenylethane, inorganic flame retardant, flame retardant synergist, antioxidant, anti-dripping agent and UV The light absorbing agent is uniformly mixed, extruded by a screw extruder, drawn into strands, cooled and granulated to obtain a polypropylene composite material, wherein the temperature range of the extruder is between 175°C and 210°C.

[0034] The polypropylene composite material is produced by mixing polypropylene resin, toughener, compatibilizer, decabromodiphenylethane, inorganic flame retardant and flame retardant synergist with corresponding additives through a screw extruder under high temperature and high shear. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com