Anti-pollution flashover coating and preparation method thereof

An anti-pollution flashover coating and catalyst technology, applied in anti-fouling/underwater coatings, fire-retardant coatings, coatings, etc., can solve the problems of unsatisfactory anti-fouling effect of coatings, and achieve the weakening of electrostatic influence, strong electron absorption and performance. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

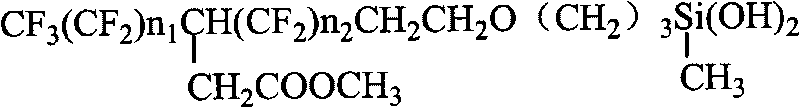

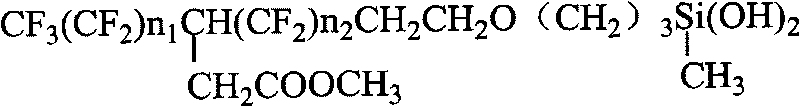

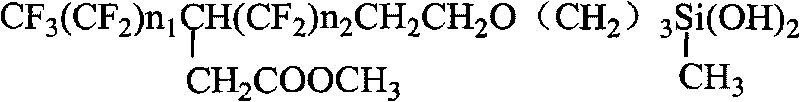

Method used

Image

Examples

Embodiment 1

[0046] Hydroxy-terminated polysiloxane (6000mm 2 / s) 25 parts (parts by weight), silicon-containing modified fluororesin 4 parts (parts by weight), trimethylsilyl-terminated polydimethylsiloxane (500mm 2 / s) 1 part (parts by weight), nano silicon dioxide (specific surface area is 175m 2 / g) 3 parts (parts by weight), 1 part (parts by weight) of decabromodiphenylethane, 1 part (parts by weight) of wollastonite, 5 parts (parts by weight) of aluminum hydroxide, 1 part (parts by weight) of pigment Add to the batching tank respectively, heat to 140°C (not less than 600mmHg) under stirring to remove water for 2 hours, after cooling, grind with three rolls, then add xylene: butyl acetate = 4: 1 (weight ratio) mixed solvent 57 Parts (parts by weight), 1 part (parts by weight) of cross-linking agent methyl tributyl ketoxime base silane, 0.2 part (parts by weight) of catalyst dibutyltin dilaurate, after the mixture is uniform, filter and pack under nitrogen protection air container. ...

Embodiment 2

[0049] The hydroxyl-terminated polysiloxane (viscosity is 8000mm 2 / s) 30 parts (parts by weight), 5 parts of silicon-modified fluororesin, trimethylsilyl-terminated polydimethylsiloxane (600mm 2 / s) 2 parts (parts by weight), nano silicon dioxide (specific surface area is 175m 2 / g) 4 parts (parts by weight), 1 part (parts by weight) of decabromodiphenylethane, 2 parts (parts by weight) of wollastonite, 4 parts (parts by weight) of aluminum hydroxide, 1 part (parts by weight) of pigment Add to the batching tank respectively, heat to 140°C (not less than 600mmHg) under stirring to remove water for 2 hours, after cooling, grind with three rolls, then add xylene: butyl acetate = 4: 1 (weight ratio) mixed solvent 49 Parts (parts by weight), 1.5 parts (parts by weight) of crosslinking agent methyltriacetonyl silane, 0.2 part (parts by weight) of catalyzer dibutyltin dilaurate, after the mixture is uniform, it is filtered and packed in an air-tight container in the container.

...

Embodiment 3

[0052] The hydroxyl-terminated polysiloxane (viscosity is 8000mm 2 / s) 30 parts (parts by weight), 5 parts of silicon-containing modified fluororesin, trimethylsilyl-terminated polydimethylsiloxane (800mm 2 / s) 2 parts (parts by weight), nano silicon dioxide (specific surface area is 175m 2 / g) 4 parts (parts by weight), 1 part (parts by weight) of decabromodiphenylethane, 2 parts (parts by weight) of wollastonite, 4 parts (parts by weight) of aluminum hydroxide, 1 part (parts by weight) of pigment Add to the batching tank respectively, heat to 140°C (not less than 600mmHg) under stirring to remove water for 2 hours, after cooling, grind with three rolls, then add xylene: butyl acetate = 4: 1 (weight ratio) mixed solvent 50 Parts (parts by weight), 1 part (parts by weight) of cross-linking agent methyl tributyl ketoxime base silane, 0.2 part (parts by weight) of catalyst dibutyltin dilaurate, after the mixture is uniform, filter and pack under nitrogen protection air contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com