A preparation method of phosphorus-containing triazole compound and its application in flame-retardant polylactic acid

A technology for triazoles and compounds, which is applied in the field of preparation of phosphorus-containing triazole compounds, can solve the problems of high addition amount, influence on material properties, etc., and achieves the effects of short cycle, easy post-processing and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

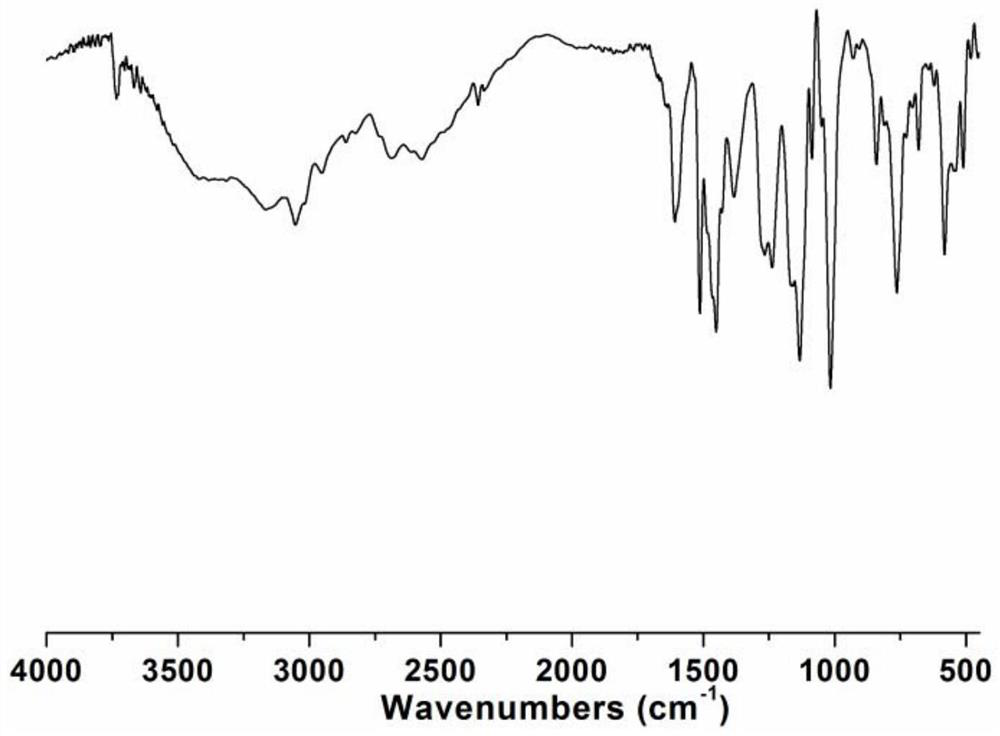

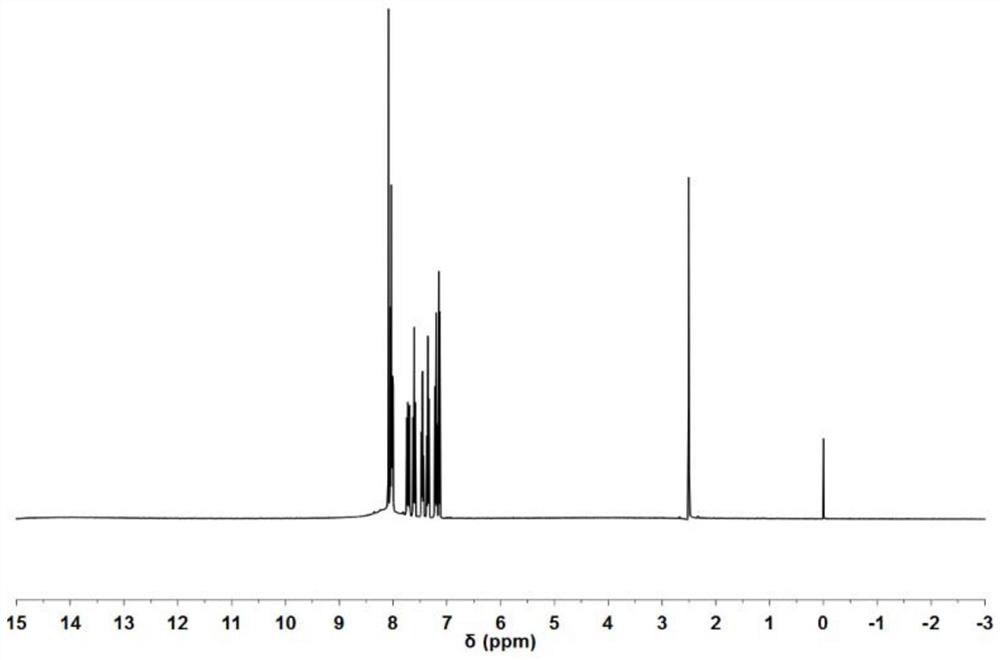

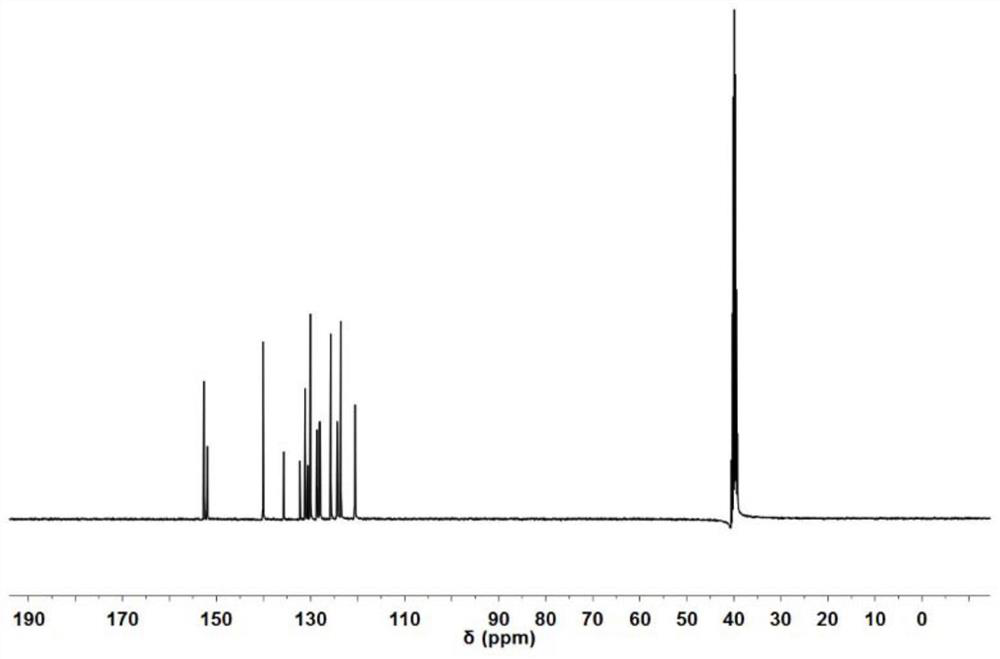

[0026] 0.1mol DOPO, 96ml (1.5mol) CH 2 Cl 2 Add it into a three-necked flask equipped with a thermometer and a mechanical stirrer. After the raw materials are evenly mixed, add 13.9ml (0.1mol) of triethylamine. After the raw materials are completely dissolved, add 3-amino-1,2,4-triazol azole 0.1mol, then add 9.6ml (0.1mol) CCl dropwise 4 , the temperature of the solution was controlled at about 5±1°C during the dropwise addition. After the dropwise addition was completed, it was reacted at room temperature for 20 hours. Finally, the resulting solution was filtered with suction, and the filter cake was taken and washed with CH 2 Cl 2 Wash once, dry at 45°C, wash twice with deionized water, and dry at 50°C to obtain a phosphorus-containing triazole compound with a yield of 69%.

Embodiment 2

[0028] 0.1mol DOPO, 96m (1.5mol) CH 2 Cl 2 Add it into a three-necked flask equipped with a thermometer and a mechanical stirrer. After the raw materials are evenly mixed, add 13.9ml (0.1mol) of triethylamine. After the raw materials are completely dissolved, add 3-amino-1,2,4-triazol azole 0.1mol, then add 9.6ml (0.1mol) CCl dropwise 4 , the temperature of the solution was controlled at 10±1°C during the dropwise addition. After the dropwise addition was completed, it was reacted at room temperature for 20 hours. Finally, the resulting solution was filtered with suction, and the filter cake was taken and washed with CH 2 Cl 2 Wash once, dry at 45°C, wash twice with deionized water, and dry at 50°C to obtain a phosphorus-containing triazole compound with a yield of 68%.

Embodiment 3

[0030] 0.1mol DOPO, 96ml (1.5mol) CH 2 Cl 2 Add it into a three-necked flask equipped with a thermometer and a mechanical stirrer. After the raw materials are evenly mixed, add 13.9ml (0.1mol) of triethylamine. After the raw materials are completely dissolved, add 3-amino-1,2,4-triazol azole 0.1mol, then add 9.6ml (0.1mol) CCl dropwise 4 , the temperature of the solution was controlled at 14±1°C during the dropwise addition. After the dropwise addition was completed, it was reacted at room temperature for 20 hours. Finally, the resulting solution was suction-filtered, and the filter cake was taken and washed with CH 2 Cl 2 Wash once, dry at 45°C, wash twice with deionized water, and dry at 50°C to obtain a phosphorus-containing triazole compound with a yield of 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com