Silicon resin coated expandable graphite flame-retardant ultrahigh molecular weight polyethylene preparation method

A technology of ultra-high molecular weight and expanded graphite, which is applied in the field of preparation of flame-retardant materials, can solve the problems of large amount of addition, loose and easy to fall off carbon layer, deterioration of mechanical properties of ultra-high molecular weight polyethylene matrix, etc., and achieve good compatibility, Good density and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

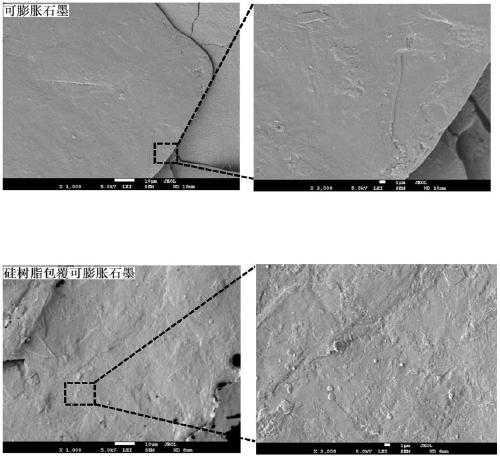

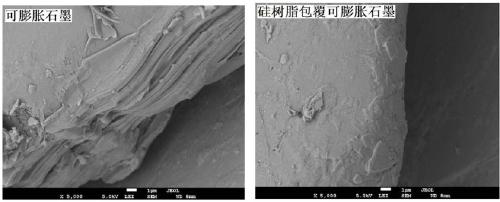

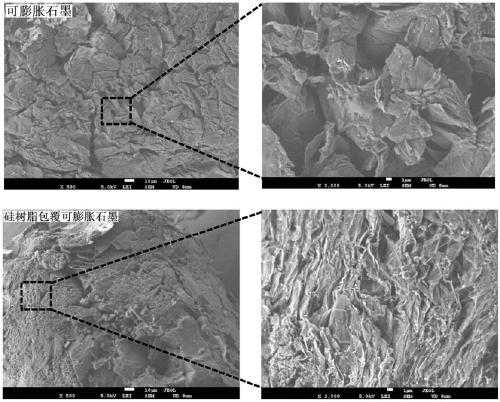

Image

Examples

Embodiment 1

[0025] A preparation method of expandable graphite flame-retardant ultra-high molecular weight polyethylene coated with silicone resin, comprising the following steps:

[0026] A. Add tetraethyl orthosilicate (TEOS), absolute ethanol and distilled water into a three-necked flask and mix, adjust the pH to 4.5, heat to 68°C, and stir for 30 minutes to obtain a mixed solution S1; among them, tetraethyl orthosilicate, The molar ratio of absolute ethanol and distilled water is 3:2:2;

[0027] B. Add 3-aminopropyltriethoxysilane (KH-570) and expandable graphite to the mixed liquid S1 prepared in step A, heat the temperature to 68°C, and keep stirring for 3 hours until the reaction is complete; The mass ratio of ethyl orthosilicate, 3-aminopropyltriethoxysilane (KH-570) and expandable graphite is 1:1:1.1;

[0028] C. filter out the product in step B, wash until the filtrate is neutral, dry the filtrate, and obtain expandable graphite coated with silicone resin;

[0029] D. Blending...

Embodiment 2

[0031] A preparation method of expandable graphite flame-retardant ultra-high molecular weight polyethylene coated with silicone resin, comprising the following steps:

[0032] A. Add tetraethyl orthosilicate (TEOS), absolute ethanol and distilled water into a three-necked flask and mix, adjust the pH to 4.8, heat to 66°C, and stir for 30 minutes to obtain a mixed solution S1; among them, tetraethyl orthosilicate, The molar ratio of absolute ethanol and distilled water is 3:2:2;

[0033] B. Add γ-glycidyl etheroxypropyltrimethoxysilane (KH-570) and expandable graphite to the mixed solution S1 prepared in step A, heat to 66°C, and keep stirring for 3 hours until the reaction is complete ; Wherein the mass ratio of ethyl orthosilicate, γ-glycidyl etheroxypropyl trimethoxysilane (KH-570) and expandable graphite is 1:1:1;

[0034] C. filter out the product in step B, wash until the filtrate is neutral, dry the filtrate, and obtain expandable graphite coated with silicone resin; ...

Embodiment 3

[0037] A preparation method of expandable graphite flame-retardant ultra-high molecular weight polyethylene coated with silicone resin, comprising the following steps:

[0038] A. Add tetraethyl orthosilicate (TEOS), absolute ethanol and distilled water into a three-necked flask and mix, adjust the pH to 4.3, heat to 69°C, and stir for 30 minutes to obtain a mixed solution S1; among them, tetraethyl orthosilicate, The molar ratio of absolute ethanol and distilled water is 3:2:2;

[0039] B. Add γ-methacryloxypropyltrimethoxysilane (KH-570) and expandable graphite to the mixed liquid S1 prepared in step A, heat the temperature to 69°C, and keep stirring for 3 hours until The reaction is complete; the mass ratio of ethyl orthosilicate, γ-methacryloxypropyltrimethoxysilane (KH-570) and expandable graphite is 1:1:1.2;

[0040] C. filter out the product in step B, wash until the filtrate is neutral, dry the filtrate, and obtain expandable graphite coated with silicone resin;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com