Preparation method of catalyst for synthesizing hexamethylenediamine intermediate 6-aminocapronitrile and synthesis method of 6-aminocapronitrile

An aminocapronitrile and intermediate technology, which is applied in the synthesis field of 6-aminocapronitrile, can solve the problems of low catalyst activity and selectivity, and achieve the effects of low cost, simple preparation method and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

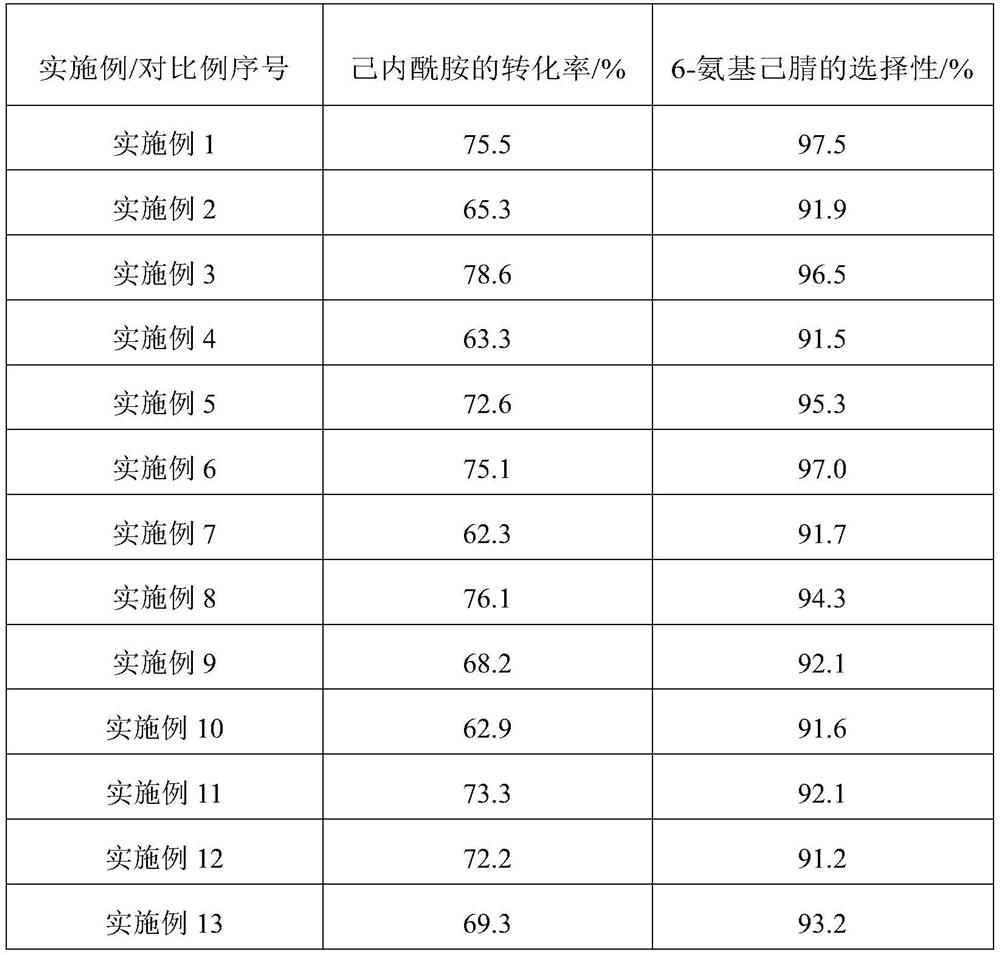

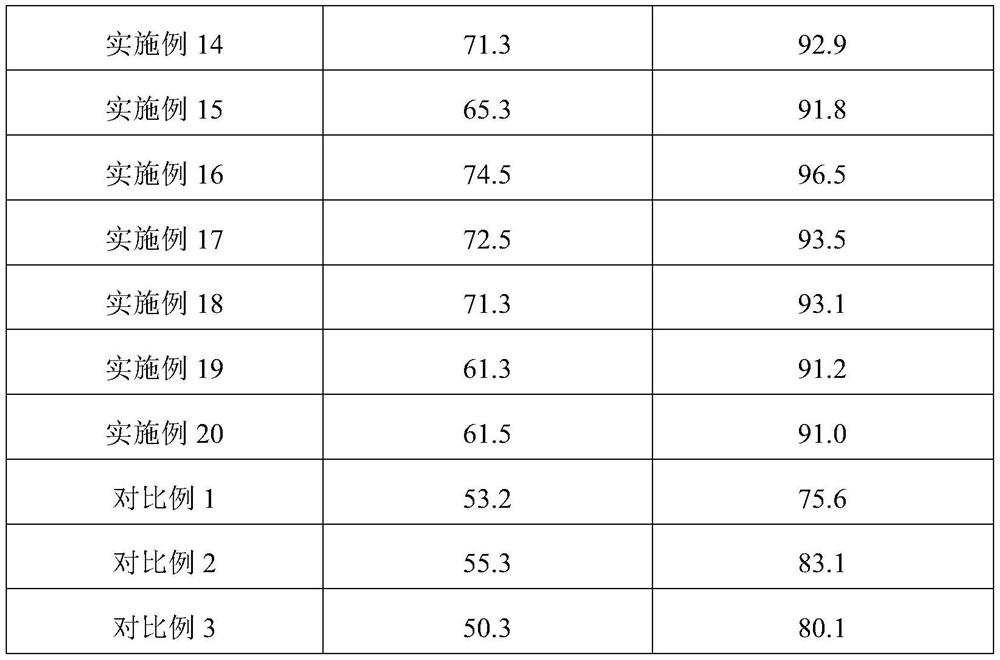

Examples

Embodiment 1

[0039] Put 150g of silicon dioxide powder into the kneader, add 30g of pseudoboehmite and 120g of water, and add 10g of nitric acid aqueous solution with a mass concentration of 65% and knead for 80min, after extrusion molding for 3 times, dry at 40°C for 20h; The dried sample was calcined at 800° C. for 4 hours to obtain a molded support with a diameter of 3 mm and a support strength of 60 N / cm.

[0040] Dissolve 20g of calcium phosphate in 80g of sulfuric acid solution with a mass concentration of 25% to form an acidic solution of modifier, then slowly add 100g of molded carrier to it, soak the solution for 60min at room temperature and put the solution in an oven at 70°C, absolute pressure Dry at 0.01 MPa for 5 hours; take out the catalyst and put it in a muffle furnace at 650°C for 5 hours to obtain a catalyst for the synthesis of hexamethylenediamine intermediate 6-aminocapronitrile, with a strength of 200 N / cm.

Embodiment 2

[0042] The difference between embodiment 2 and embodiment 1 is that

[0043] Add 1.5g of pseudo-boehmite to prepare a shaped support with a support strength of 20N / cm, and finally obtain a catalyst for the synthesis of hexamethylenediamine intermediate 6-aminocapronitrile with a strength of 75N / cm.

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is that

[0046] Add 150g of pseudo-boehmite to prepare a shaped support with a support strength of 70N / cm, and finally obtain a catalyst for the synthesis of hexamethylenediamine intermediate 6-aminocapronitrile with a strength of 230N / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com