Process and equipment for preparing chinlon delustering agent

A matting agent, nylon technology, used in rayon manufacturing, single-component polyamide rayon, fiber chemical characteristics, etc., can solve the problems of different particle sizes, uneven dispersion of titanium dioxide, etc., to achieve uniform dispersion and prevent sedimentation. and agglomeration, reducing the effect of preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

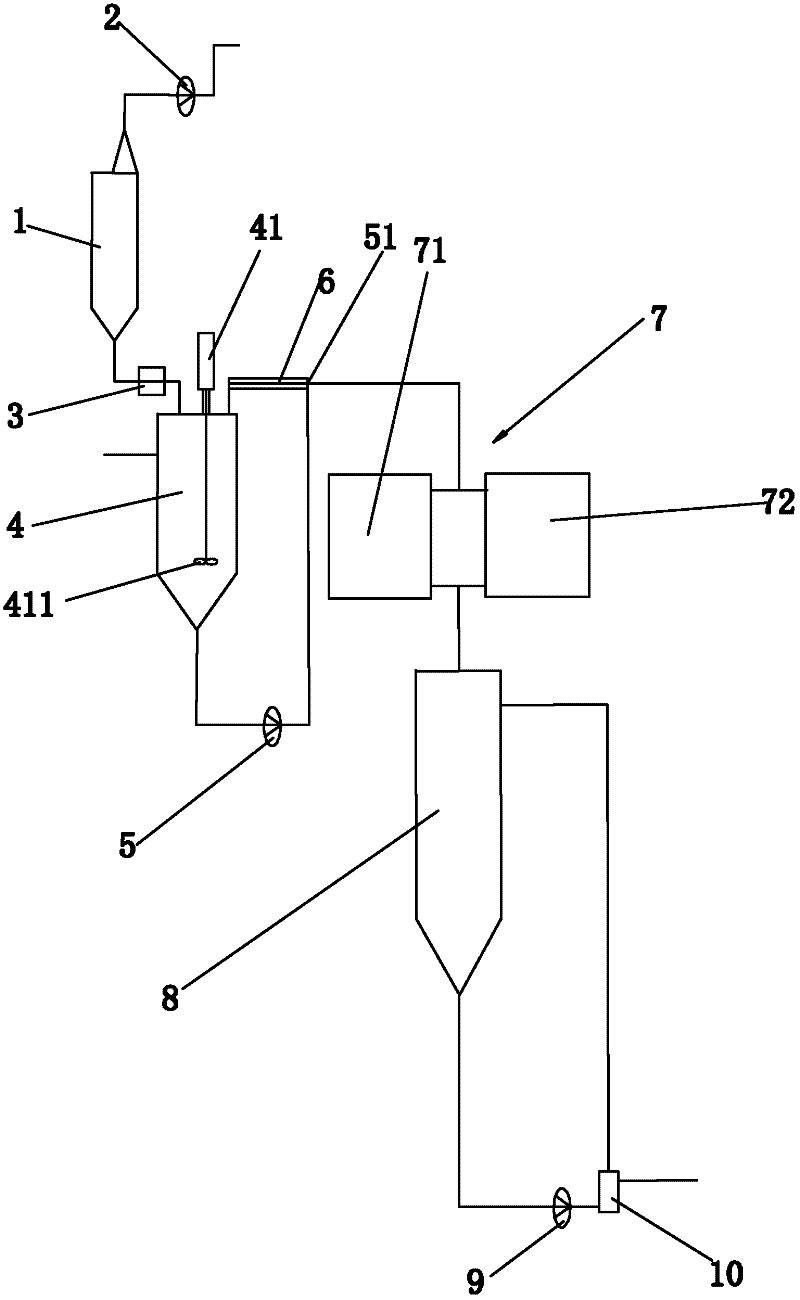

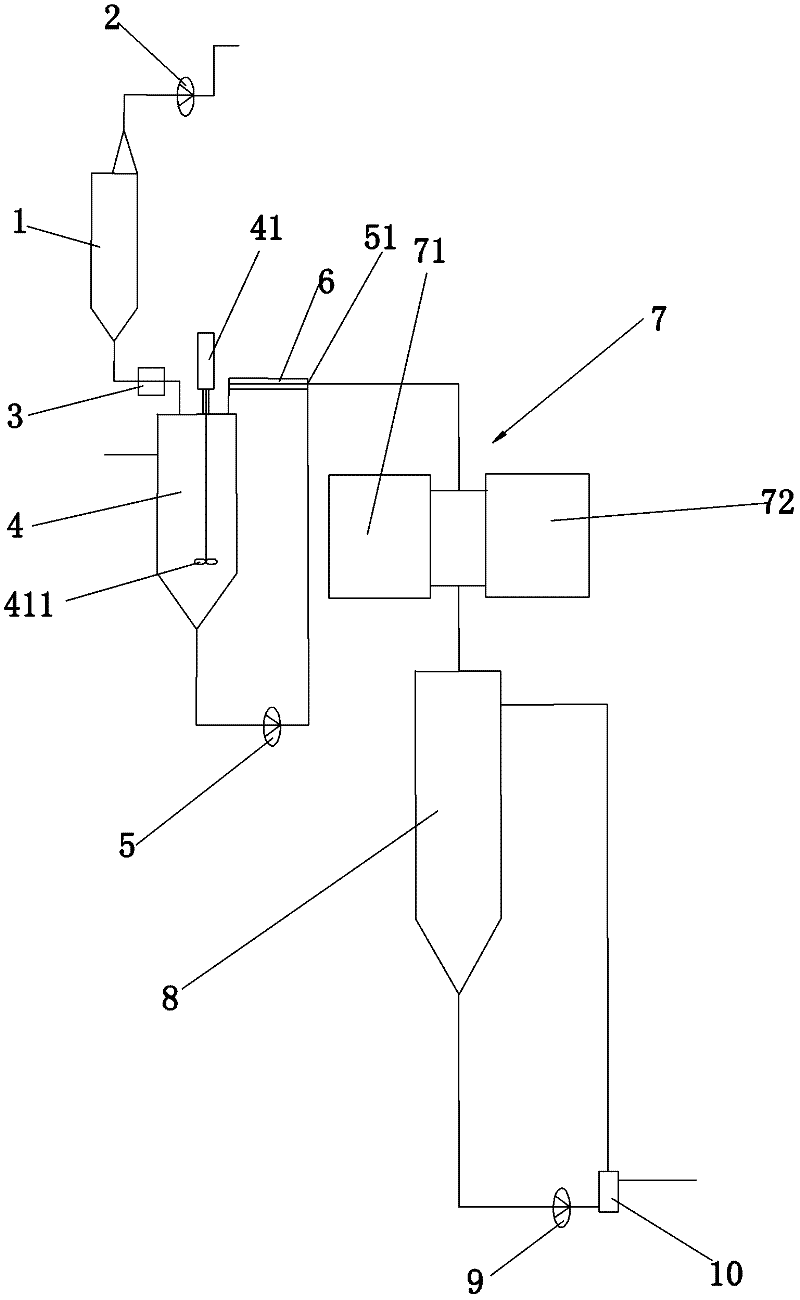

[0029] Deionized water is added in the preparation tank 4 by flowmeter, stops after the accumulative addition amount of deionized water is 1375Kg, and deionized water among the present invention is desalinated water, and in this process, the bottom valve of preparation tank 4 is closed, when deionized water When the deionized water is added to the stirring liquid level, the agitator 41 is started at a low speed, and the rotating speed of the agitator is 120rpm at this time, and a 10% sodium phosphate solution is configured at the same time, and 450 g of the prepared 10% sodium metaphosphate solution is poured into the preparation tank 4 , and then take 15 bags of titanium dioxide, each bag of titanium dioxide weighs 25 kilograms. The present invention adopts Konnos titanium dioxide 1073, slowly pours it into the feeding hopper, and evenly adds it into the preparation tank after being pre-dispersed by the vibrator 3 . After all the titanium dioxide has been added to the prepara...

Embodiment 2

[0031]Deionized water is added in the preparation tank 4 by flowmeter, stops after the accumulative addition amount of deionized water is 1375Kg, and deionized water in the present invention is desalinated water, and in this process, the bottom valve of preparation tank 4 is closed, when deionized water When the deionized water is added to the stirring liquid level, the agitator 41 is started at a low speed, and the rotational speed of the agitator is 120 rpm. Configure 10% sodium phosphate solution simultaneously, get 450g and prepare 10% sodium metaphosphate solution and pour in the preparation tank 4, then get 15 bags of titanium dioxide, and the weight of every bag of titanium dioxide is 25 kilograms. The present invention uses Konnos titanium dioxide 1073, slowly pours it into the hopper, and evenly adds it to the preparation tank 4 after being pre-dispersed by the vibrator 5 . After all the titanium dioxide has been added to the preparation tank 4, the agitator 41 is ope...

Embodiment 3

[0033] Deionized water is added in the preparation tank 4 through the flow meter, and stops after the cumulative addition of deionized water is 1000Kg. The deionized water in the present invention is desalinated water. In this process, the bottom valve of the preparation tank 4 is closed. When the deionized water is added to the stirring liquid level, the agitator 41 is started at a low speed, and the rotational speed of the agitator is 120 rpm. Configure 8% sodium phosphate solution simultaneously, get 450g and prepare 8% sodium metaphosphate solution and pour in the preparation tank 4, then get 12 bags of titanium dioxide, and the weight of every bag of titanium dioxide is 25 kilograms. The present invention uses Konnos titanium dioxide 1073, slowly pours it into the hopper, and evenly adds it to the preparation tank 4 after being pre-dispersed by the vibrator 5 . After all the titanium dioxide has been added to the preparation tank 4, the agitator 41 is operated at a high s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com