Preparation method for cobalt-nickel bimetal metaphosphate nanometer array loaded on carbon cloth substrate

A metaphosphate and nano-array technology, applied in chemical instruments and methods, electrodes, electrolysis processes, etc., can solve the problems of anode catalyst stability and low catalytic activity, high cost of noble metals and their oxides, and achieve excellent catalytic stability , Facilitate rapid release and optimize the effect of electronic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

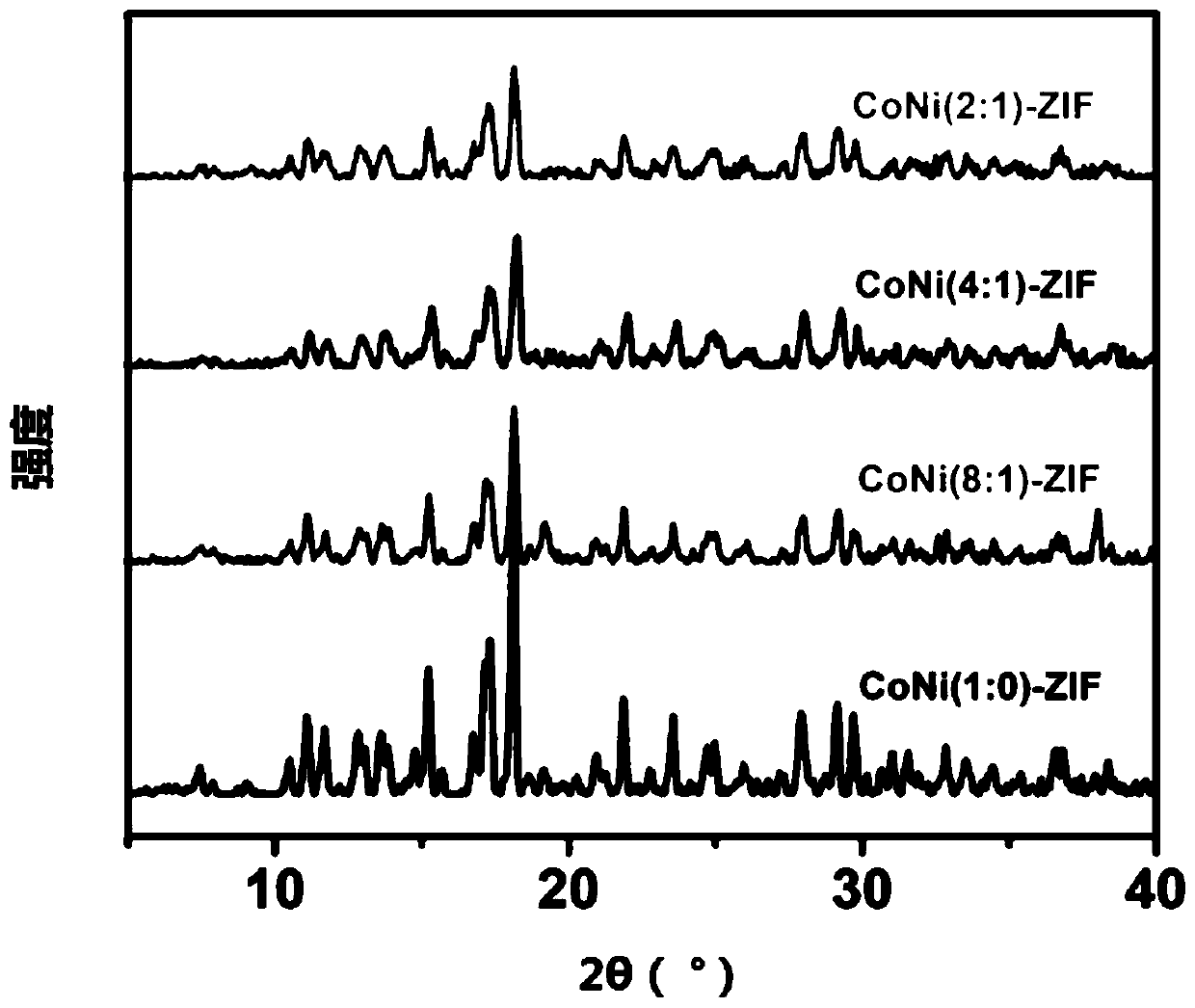

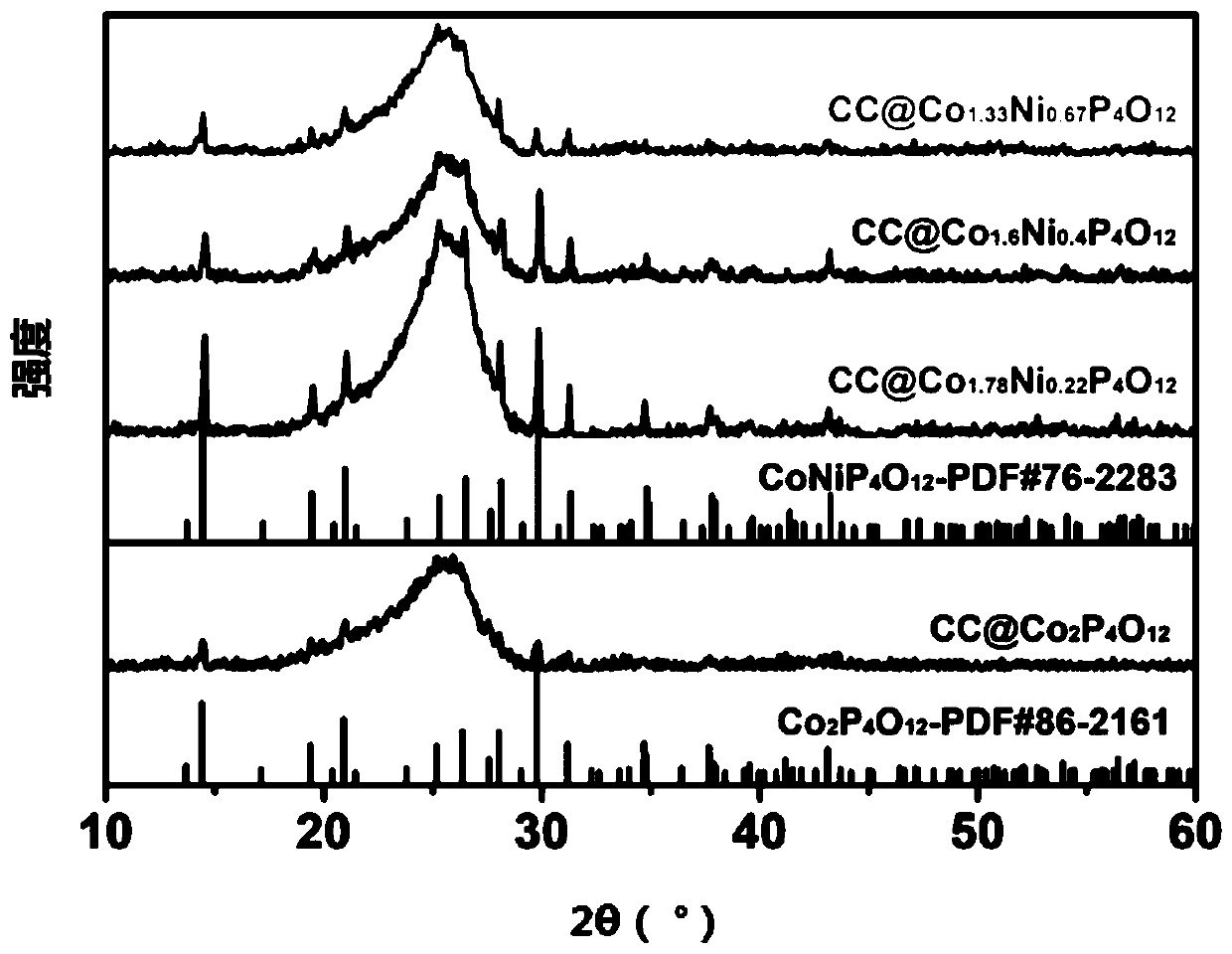

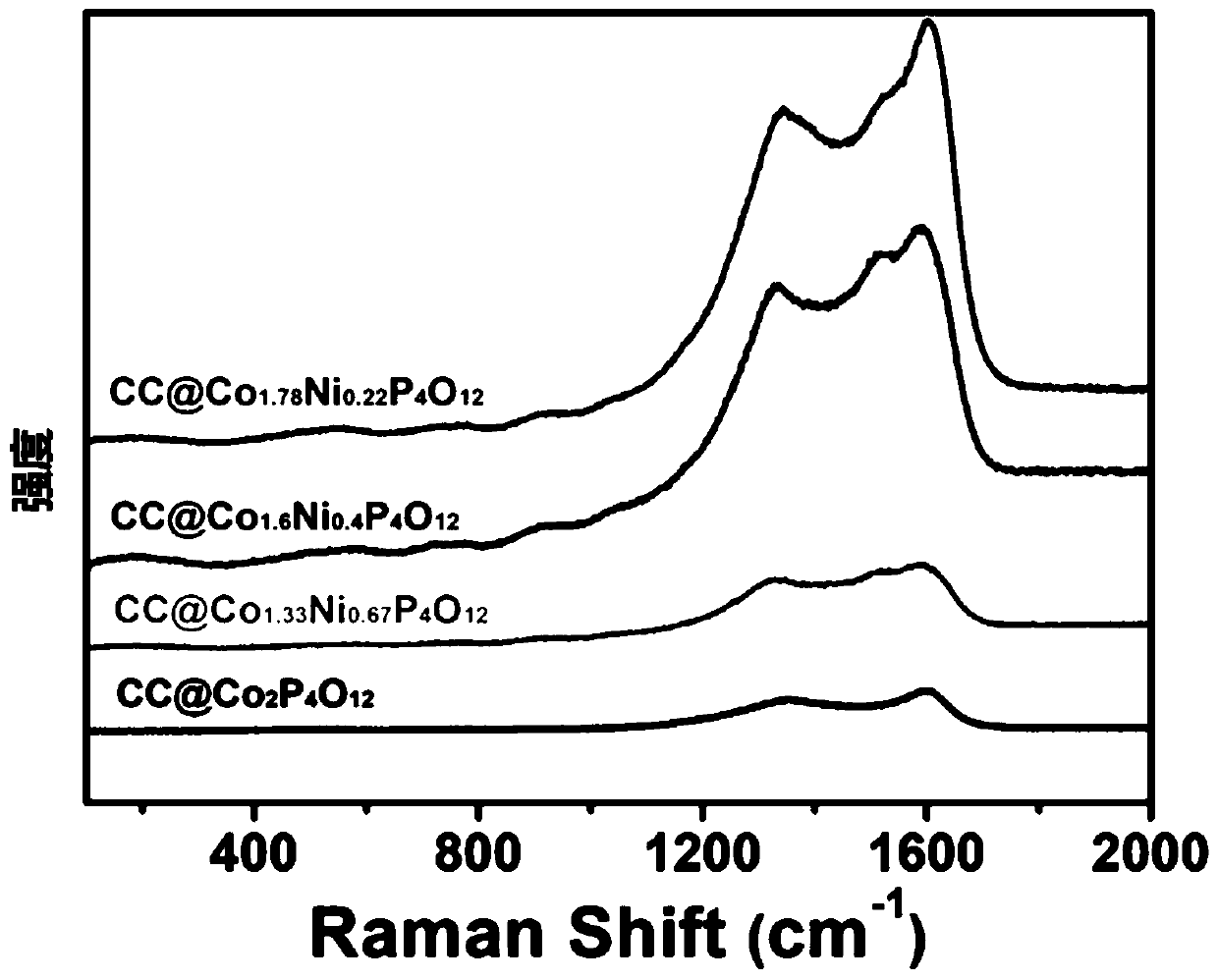

[0058] Embodiment 1: In this embodiment, a Co supported on a carbon cloth substrate 2-x Ni x P 4 O 12 -The preparation method of C nanoarrays is carried out according to the following steps:

[0059] 1. The carbon cloth was ultrasonically washed in acetone, ethanol and aqueous solution in turn, and then washed in concentrated HNO 3 Medium ultrasonic washing, then washing with water, and drying to obtain the treated carbon cloth;

[0060] Second, the Co(NO 3 ) 2 ·6H 2 O and Ni (NO 3 ) 2 ·6H 2 Disperse O into deionized water, stir evenly with magnetic force, mark as solution A; disperse 2-methylimidazole in deionized water, mark as solution B, under continuous magnetic stirring, pour solution B into solution A, stir , the obtained mixed solution is marked as solution C;

[0061] 3. Immerse the carbon cloth treated in step 1 into the solution C obtained in step 2, stir continuously for 2-6 hours at room temperature, then take out the carbon cloth, wash it with deionize...

specific Embodiment approach 2

[0067] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the concentration of HNO 3 Medium ultrasonic washing 4 ~ 4.5h. Others are the same as the first embodiment.

specific Embodiment approach 3

[0068] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: in step 2, the Co(NO) in solution A 3 ) 2 ·6H 2 The concentration of O is 25 to 50 mmol / L. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com