Method for producing glutathione based on enzymic method in vitro

A technology of glutathione and bifunctional enzyme, which is applied in the direction of fermentation, etc., can solve the problems of not being able to meet the market demand well, not easy to separate the product later, and difficult to increase the product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1 Cloning of glutathione synthesis bifunctional enzyme gene gs of Pasteurella multocida strain and construction of recombinant vector

[0035] 1.1 Cloning of GS gene of Pasteurella multocida strain

[0036] The DNA of glutathione synthesizing bifunctional enzyme GS gene in Pasteurellamultocida strain was synthesized by whole gene synthesis method. Using the gene DNA as a template, primers were designed according to the GenBank sequence, and the corresponding enzyme cutting sites (NdeI and EcoRI) and protective bases were added.

[0037] The primers used for PCR amplification of glutathione synthesis bifunctional enzyme GS gene are as follows:

[0038] Upstream primer: 5'-GCATATGATGGCCAAGAAGGAC-3'

[0039]Downstream primer: 5'-GCTCGAGTTACTTGGCGAG-3'

[0040] The PCR system reaction system contains 0.2 μL of genomic DNA, 0.5 μL of upstream and downstream primers, 10 μL of Extaq mixture, and added double distilled water to make up to 20 μL. The reaction conditions were...

Embodiment 2

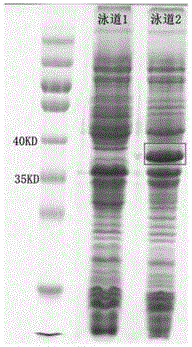

[0044] 1 Cloning of ppk polyphosphate kinase gene in Corynebacterium glutamicum strain and construction of recombinant vector

[0045] The ppk polyphosphokinase gene in Escherichia coli strain was synthesized by the method of total gene synthesis. Using the whole gene of the strain as a template, primers were designed according to the GenBank sequence, and corresponding enzyme cutting sites (NcoI and EcoRI) and protective bases were added.

[0046] The primers used for PCR amplification of polyphosphate kinase gene ppk are as follows:

[0047] Upstream primer: 5'-GCATATGATGACCGCCACCGATTC-3'

[0048] Downstream primer: 5'-GAAGCTTCCGGTTGGTAGCTGTGAC-3'

[0049] The PCR system reaction system contains 0.2 μL of genomic DNA, 0.5 μL of upstream and downstream primers, 10 μL of Extaq mixture, and added double distilled water to make up to 20 μL. The reaction conditions were pre-denaturation at 94°C for 5 min, denaturation at 94°C for 30 s, annealing at 55°C for 30 s, extension at ...

Embodiment 3

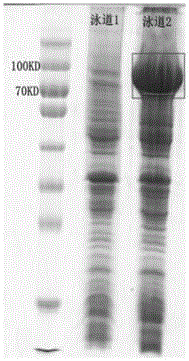

[0053] Transform the constructed expression vector pET22b-gs plasmid into BL21(DE3) Escherichia coli, use LB medium, grow at 37°C until the OD600 is about 0.4-1.0, induce with 0.1mM-1mM IPTG, at 30 Intracellular expression was carried out in culture at ℃. Transform the control empty vector pET22b into BL21(DE3) Escherichia coli, induce expression under the same conditions as above, and conduct protein electrophoresis to verify the expression result of the expressed recombinant protein. The protein electrophoresis is as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com