Hydrogenation catalyst composition, preparation method and use thereof

A technology of hydrogenation catalyst and composition, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., and can solve the problems of deterioration and heavy crude oil properties, etc. Achieve high hydrogenation activity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to the preparation method of the hydrogenation catalyst composition provided by the present invention, the preparation method of the catalyst further includes the step of introducing a binder. The binder can be introduced into the composition by any existing method, preferably by directly mixing the hydrogenation catalyst composition obtained through the reaction with the binder. Based on the catalyst, the amount of the binder introduced is usually not more than 95% by weight, preferably not more than 75% by weight, more preferably not more than 50% by weight, more preferably not more than 30% by weight.

[0040] According to the hydroprocessing method provided by the present invention, the used catalyst is preferably presulfurized in the presence of sulfide before use, so as to convert it into a sulfurized type. The vulcanization condition is 360-400° C. for 2-4 hours. The sulfide may be one or more of elemental sulfur, hydrogen sulfide, carbon disulfide, DM...

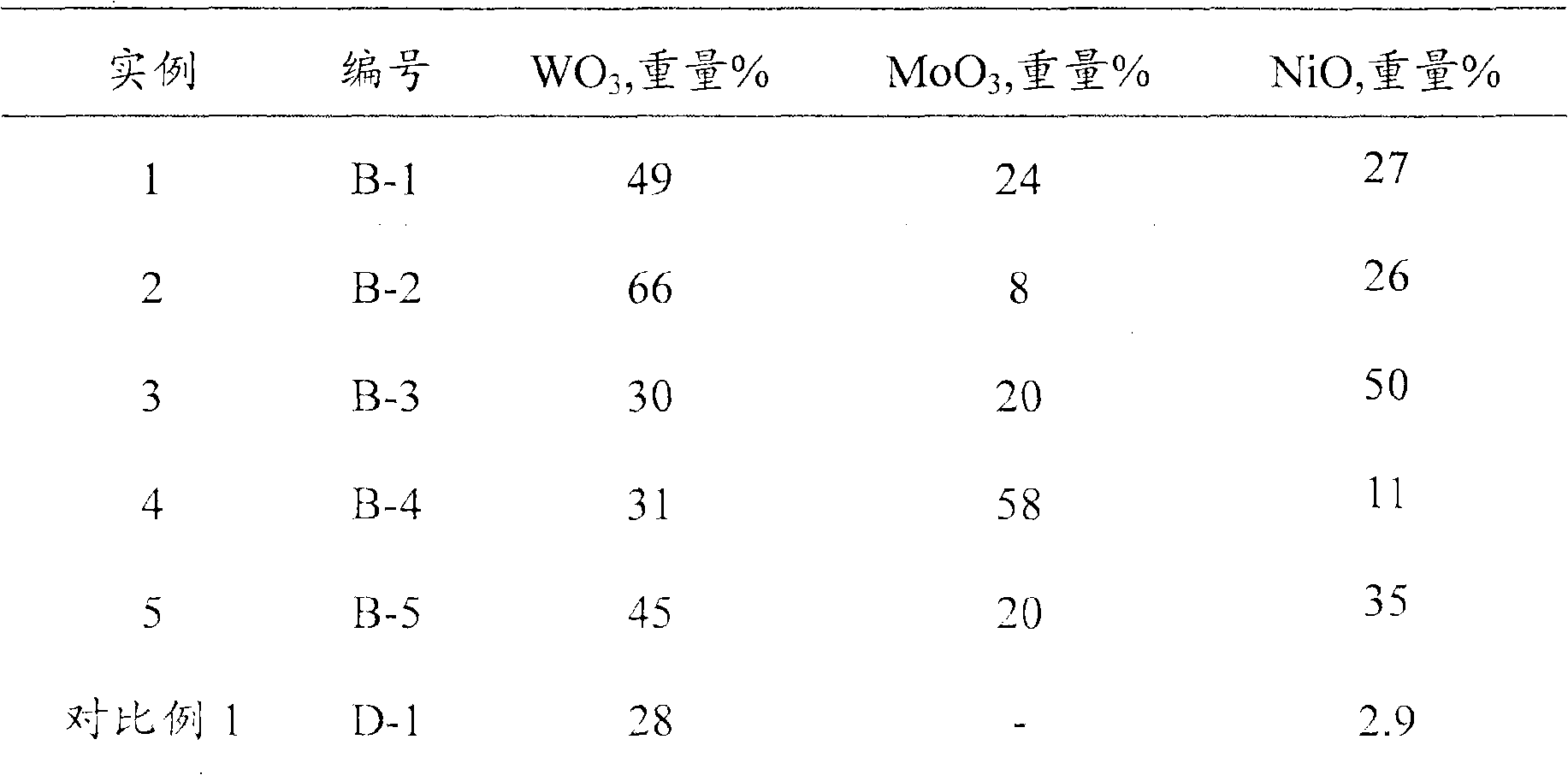

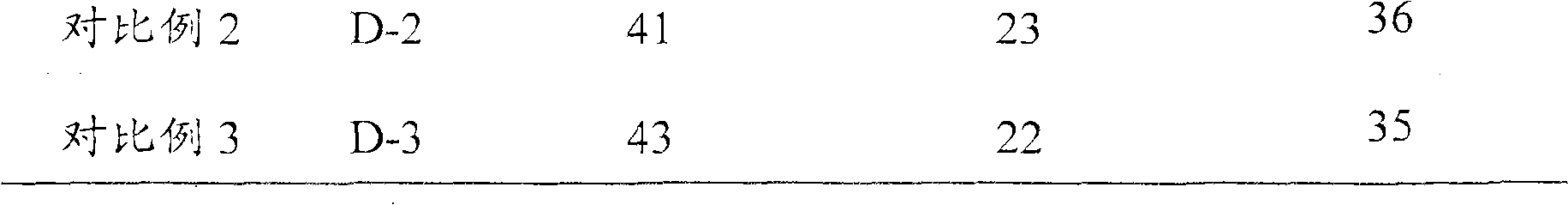

example 1

[0047] Weigh ammonium metatungstate ((NH 4 ) 2 W 4 o 13 18H 2 O, Sichuan, chemically pure) 5.4 grams, ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, Tianjin, chemically pure) 3 grams, nickel nitrate (Ni(NO 3 ) 2 ·6H 2 O, Yixing, chemically pure) 10 grams join in 100 milliliters of waters, add 1.4 gram tetraethylammonium bromide ((C) under stirring 2 h 5 ) 4 NBr (Beijing, analytically pure), add dropwise ammonia water with a concentration of 25% until the pH value of the mixed solution is 9, place the mixed solution in a synthesis reaction kettle, and conduct hydrothermal synthesis at 50°C under airtight conditions for 12 hours, then cool and filter , washed with water, and the filter cake was dried at 120° C. for 2 hours. Catalyst B-1 was obtained, its composition is shown in Table 1, and the positions of the characteristic peaks in the diffraction pattern are shown in Table 2.

example 2

[0049] Weigh ammonium metatungstate ((NH 4 ) 2 W 4 o 13 18H 2 O, Sichuan, chemically pure) 9 grams, ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O, Tianjin, chemically pure) 1 g, nickel nitrate (Ni(NO 3 ) 2 ·6H 2 0, Yixing, chemically pure) 10 grams join in 100 milliliters of waters, add 8.9 gram tetrapropyl ammonium bromide ((C) under stirring 3 h 7 ) 4 NBr, Beijing, analytically pure), dripping concentration of 25% ammonia water to the pH value of the mixed solution is 9, the mixed solution is placed in a synthesis reaction kettle, and hydrothermally synthesized at 50 ° C under airtight conditions for 8 hours, then cooled, Filter, wash with water, and dry the filter cake at 140°C for 3 hours. Catalyst B-2 was obtained, its composition is shown in Table 1, and the positions of the characteristic peaks in the diffraction pattern are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com