Preparation method of machine-made sand fine aggregate

A technology of machine-made sand and fine aggregate, applied in the direction of grain processing, etc., can solve the problems of unfavorable fine aggregate fineness modulus, affecting the workability of ready-mixed concrete pumping concrete construction, and accurate regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

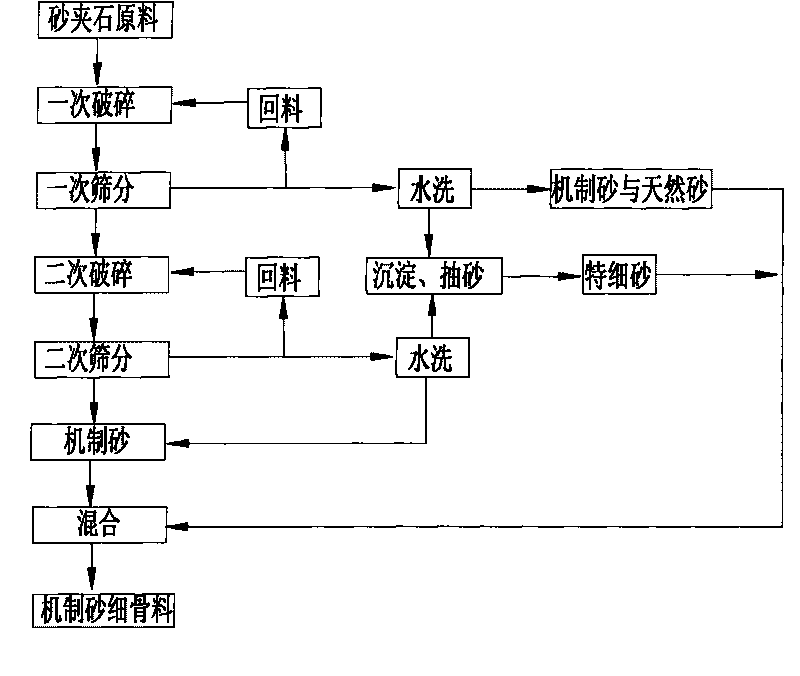

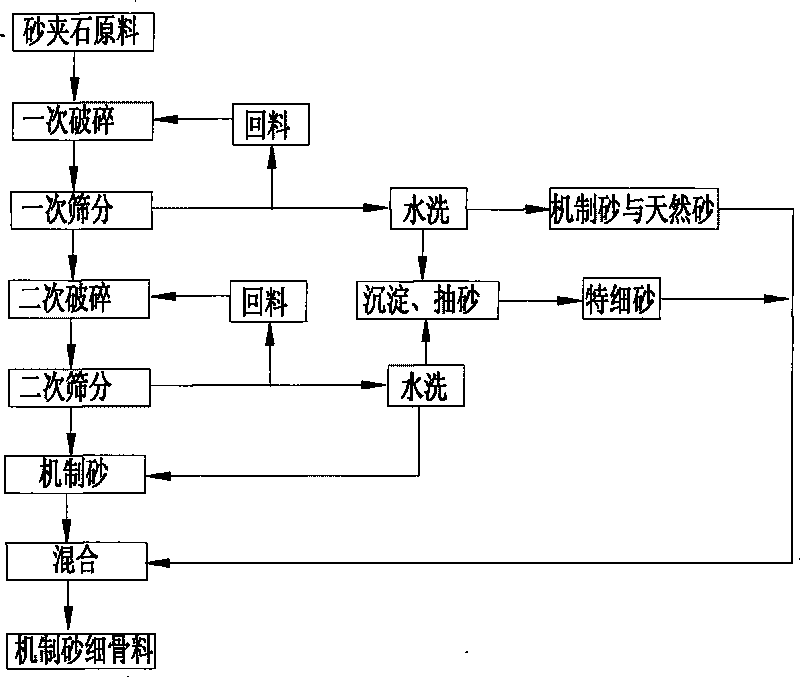

[0017] Such as figure 1 As shown, the present invention produces machine-made sand fine aggregate with a certain fineness modulus through the sand making process. For realizing flow process technology of the present invention, it has present embodiment as follows:

[0018] (1) The loader puts the raw materials that have been preliminarily cleaned into the feeding bin;

[0019] (2) The feeding bin enters the impact crusher through the feeder, and the gap between the blow bar and the impact plate is initially set to 70mm, and the gap is continuously adjusted according to the discharge situation during the working period;

[0020] (3) After the first crushing, the belt conveyor is transported to the sand screening machine with two layers of screens, and the broken pebbles larger than 45mm are privately returned to the impact crusher through the belt conveyor; the pebbles that meet the requirements enter the second layer of screen The natural sand and machine-made sand less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com