Distribution valve, pumping system and pumping machine

A pumping system and distribution valve technology, which is applied in the field of distribution valves, pumping systems and pumping machinery, can solve the problem of long reversing time, reversing noise, reversing resistance, reversing impact and large reversing wear, S tube Issues such as dispensing valves not working efficiently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

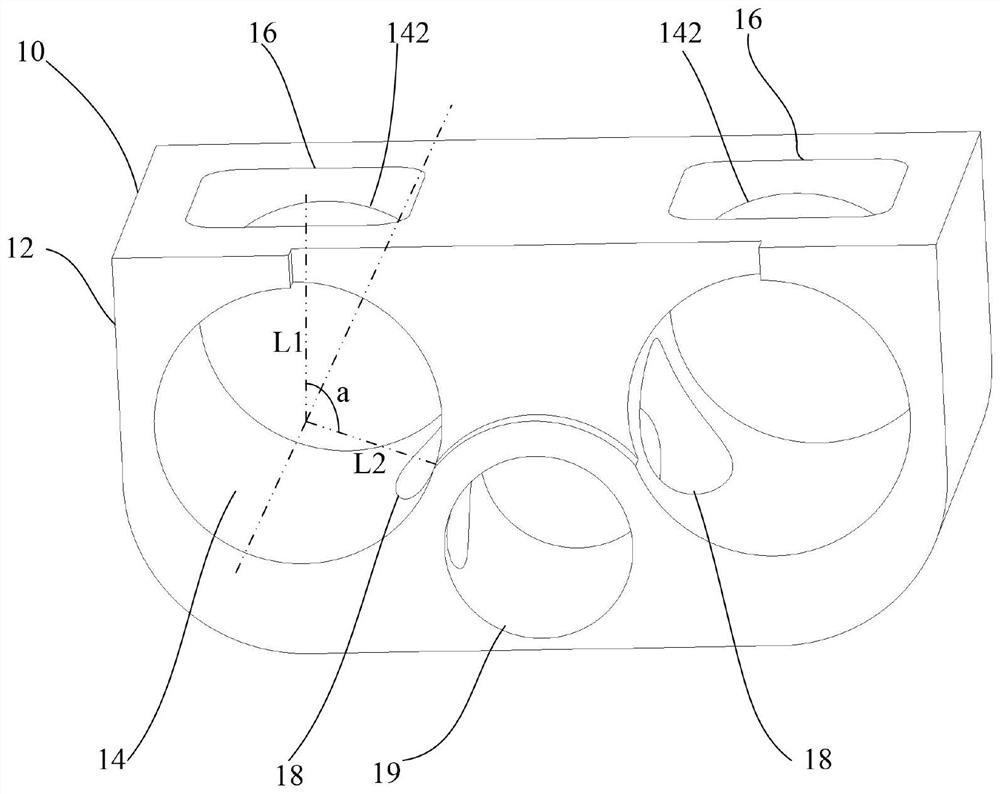

[0055] Specifically, such as figure 1 As shown, in the first implementation of the present invention, the feed port 16 and the discharge port 18 are arranged along the radial extension of the valve hole 14, and the feed port 16 and the discharge port 18 have an included angle a, and the included angle a is equal to 120°.

[0056] In the above setting, the feed port 16 and the discharge port 18 are arranged according to the above angle, so that the valve core 20 only needs to rotate 120° to realize the reversing function of the distribution valve 100, thereby ensuring that the distribution valve 100 can be used in the pumping operation. It can work stably and efficiently while meeting the requirements of the noise reduction method. Further, the application range of the distribution valve 100 is expanded.

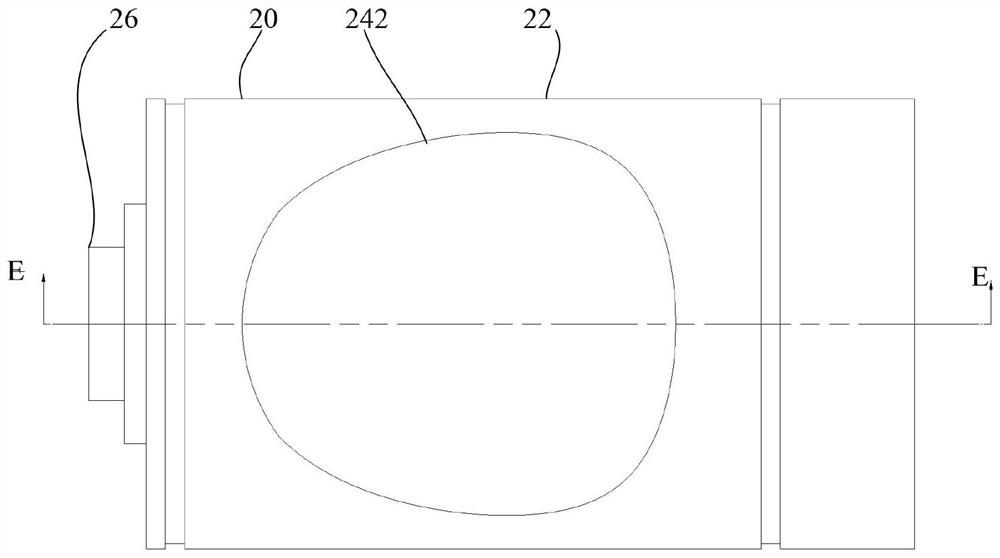

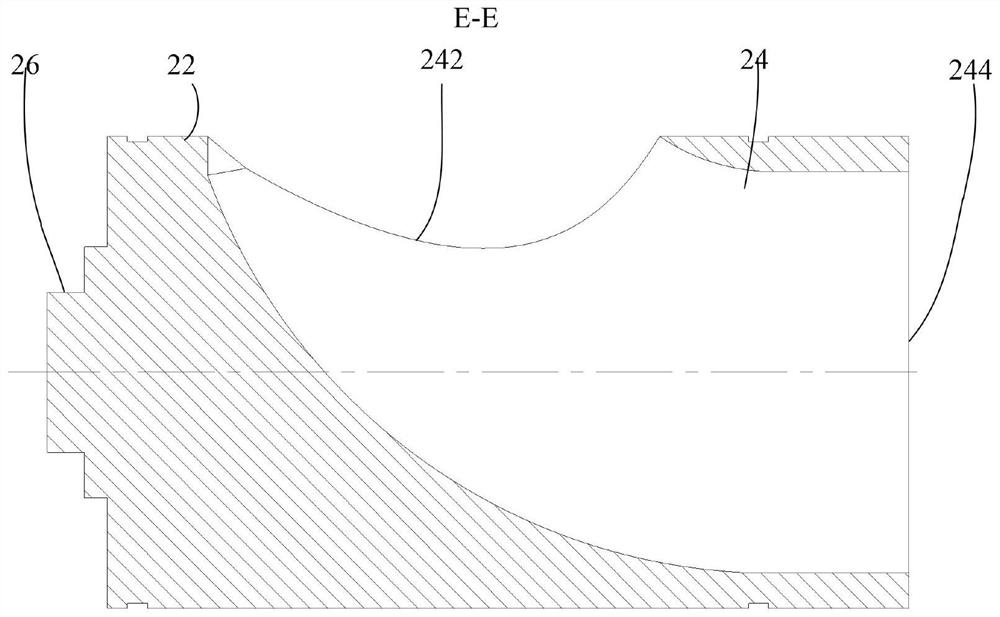

[0057] It should be noted that, usually, when the valve core 20 is initially installed into the valve body 10, the first flow channel port 242 of the valve core 20 is aligne...

Embodiment 2

[0065] Embodiment two has following difference with embodiment one:

[0066] Specifically, such as Figure 4 As shown, in the second embodiment of the present invention, the feed port 16 and the discharge port 18 are arranged along the radial extension of the valve hole 14, and the feed port 16 and the discharge port 18 have an included angle a, and the included angle a is equal to 180°.

[0067] In the above arrangement, the feed port 16 and the discharge port 18 are arranged according to the above angles, and the reversing function of the distributing valve 100 can be realized only by rotating 180°. In addition, the included angle a is set to 180°, so that the spool 20 can rotate 360° in one direction, that is, rotate 360° clockwise or counterclockwise, so that the two reversing functions of the dispensing valve 100 can be realized, without the need for As in the first one, it is necessary to reciprocate the spool 20 to realize the two reversing of the distribution valve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com