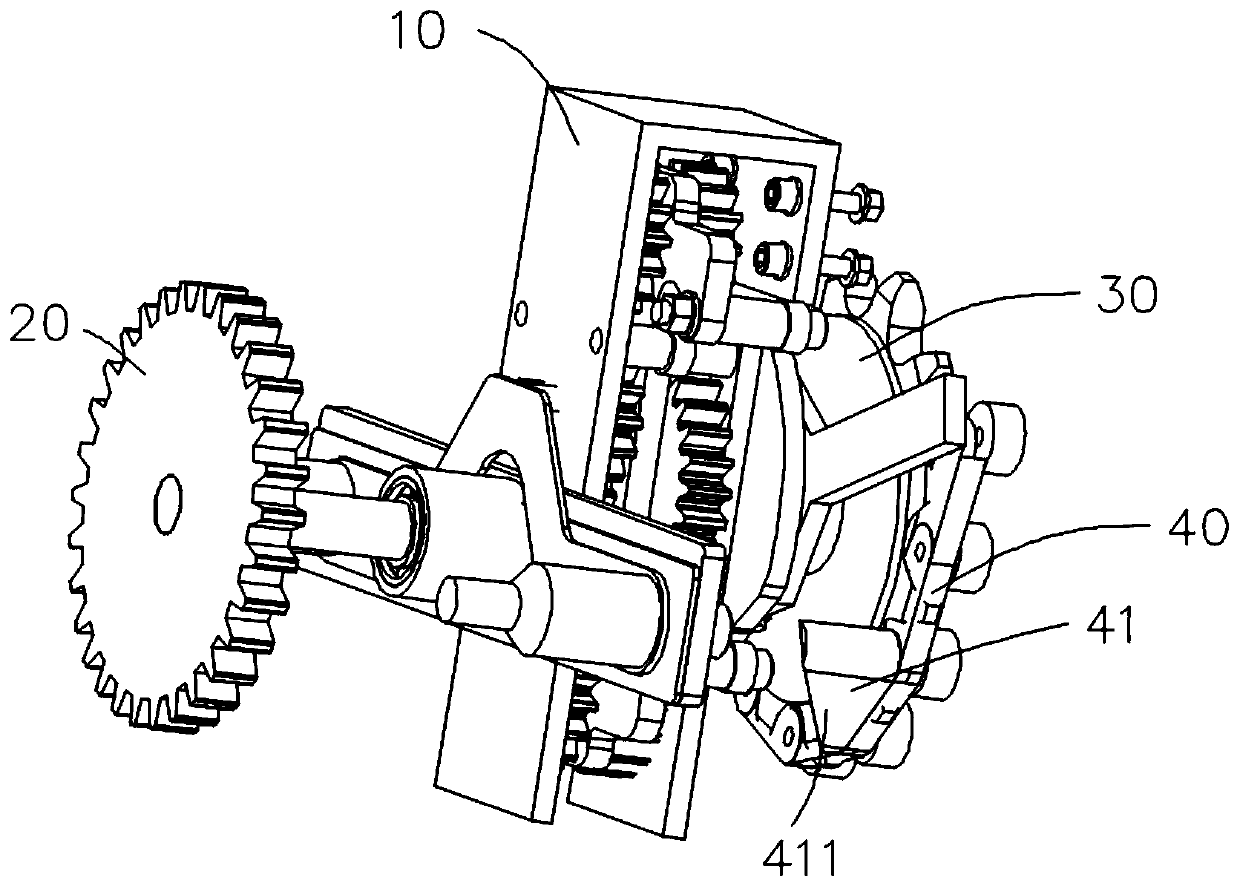

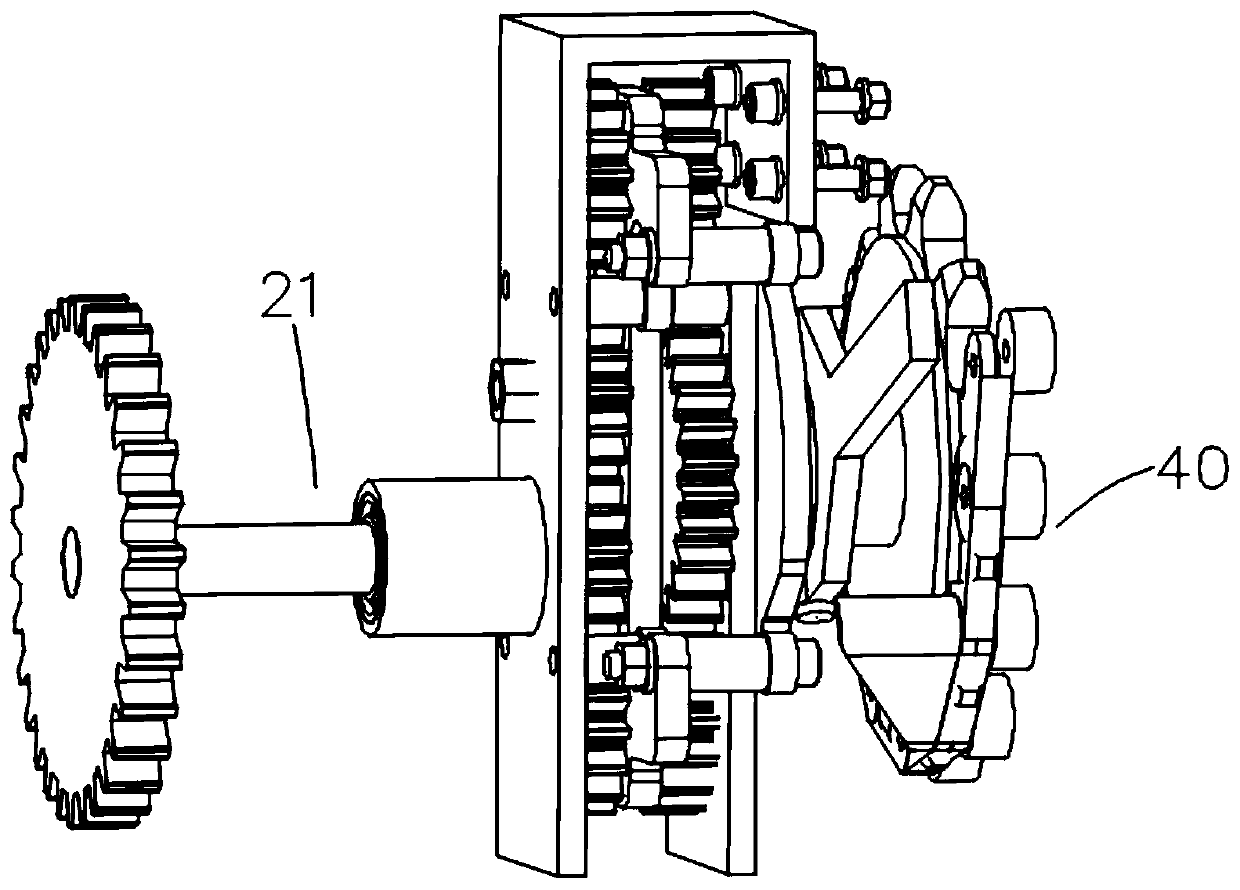

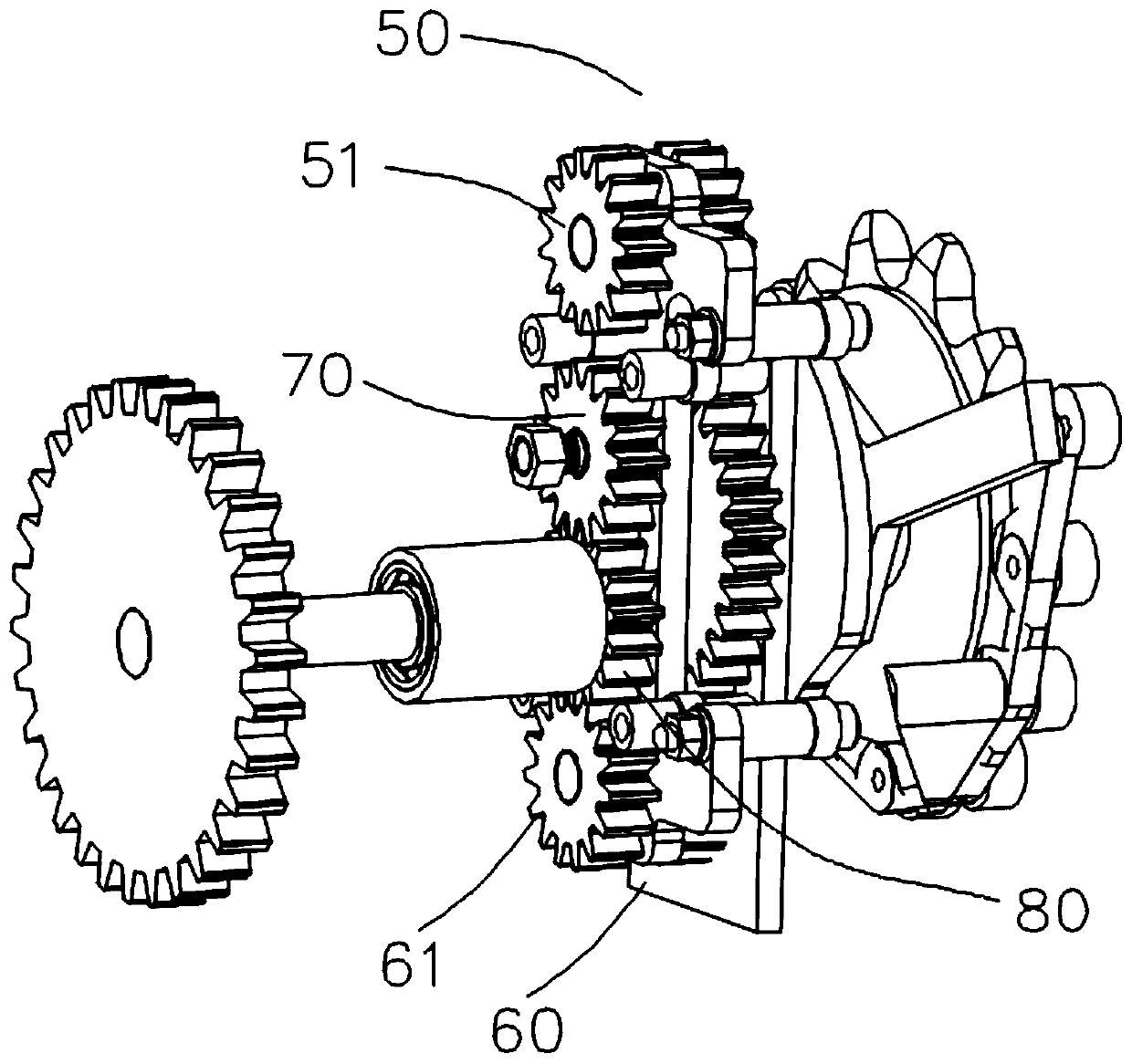

Reversing mechanism

A technology of reversing mechanism and transmission structure, which is applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following, the present invention will be further described in conjunction with the drawings and specific implementations. It should be noted that, provided that there is no conflict, the following embodiments or technical features can be combined to form new embodiments. .

[0027] It should be noted that when a component is said to be "fixed to" another component, it can be directly on the other component or a central component may also exist. When a component is considered to be "connected" to another component, it can be directly connected to another component or there may be a centered component at the same time. When a component is considered to be "installed on" another component, it can be directly installed on another component or a centered component may exist at the same time. The terms "vertical", "horizontal", "left", "right" and similar expressions used herein are for illustrative purposes only.

[0028] Unless otherwise defined, all technical and scien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com