Method for preparing low-carbon metal manganese iron by using manganese-poor powdered ore

A technology for metal ferromanganese and poor manganese ore, applied in the direction of solid separation, etc., can solve the problems of increasing refining cost, time-consuming and laborious, increasing energy consumption of smelting ferromanganese alloy product impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention will be further described below in conjunction with accompanying drawing:

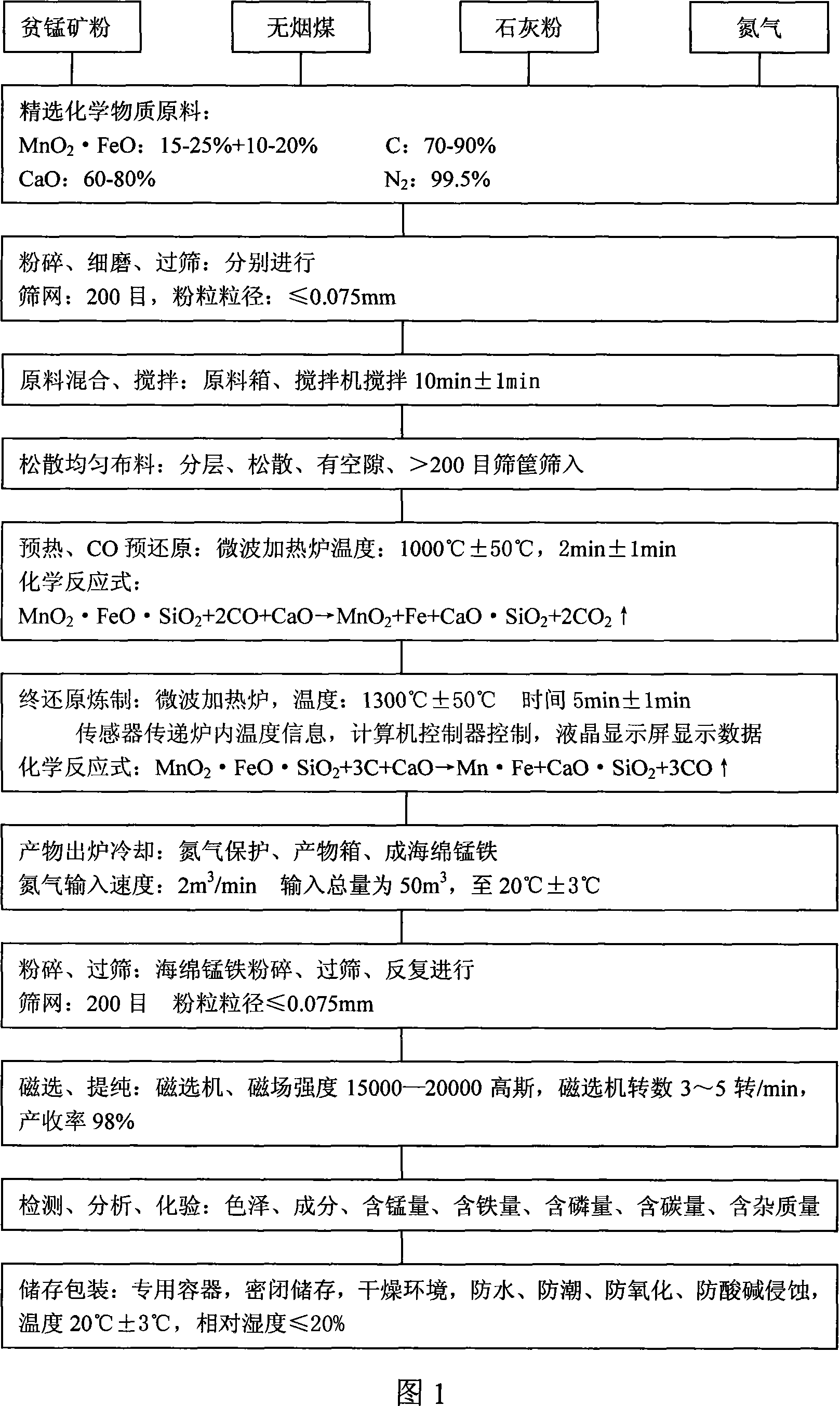

[0090] As shown in Fig. 1, it is a flow chart of the preparation process, which is the whole process of producing low-carbon metal ferromanganese. From the raw material to storage, it must be strictly operated according to the procedure.

[0091] The raw manganese ore powder, anthracite powder, and lime powder used in the preparation of chemical substances are determined according to the preset quantity ratio, and can be calculated according to this quantity ratio when it is produced on a large scale.

[0092] Depleted manganese ore powder is mainly composed of 15-25% MnO 2 , 10-20% FeO composition, the others are metal and non-metal impurities, which are removed or become waste slag in the process of carbon reduction, refining, and magnetic separation.

[0093] The crushing, fine grinding, and sieving of raw materials should be carried out by machines respectively, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com