Spherical and radial magnesium carbonate and preparation method thereof

A radial, magnesium carbonate technology, applied in magnesium carbonate and other directions, to achieve the effects of wide source, low cost, improved morphology and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

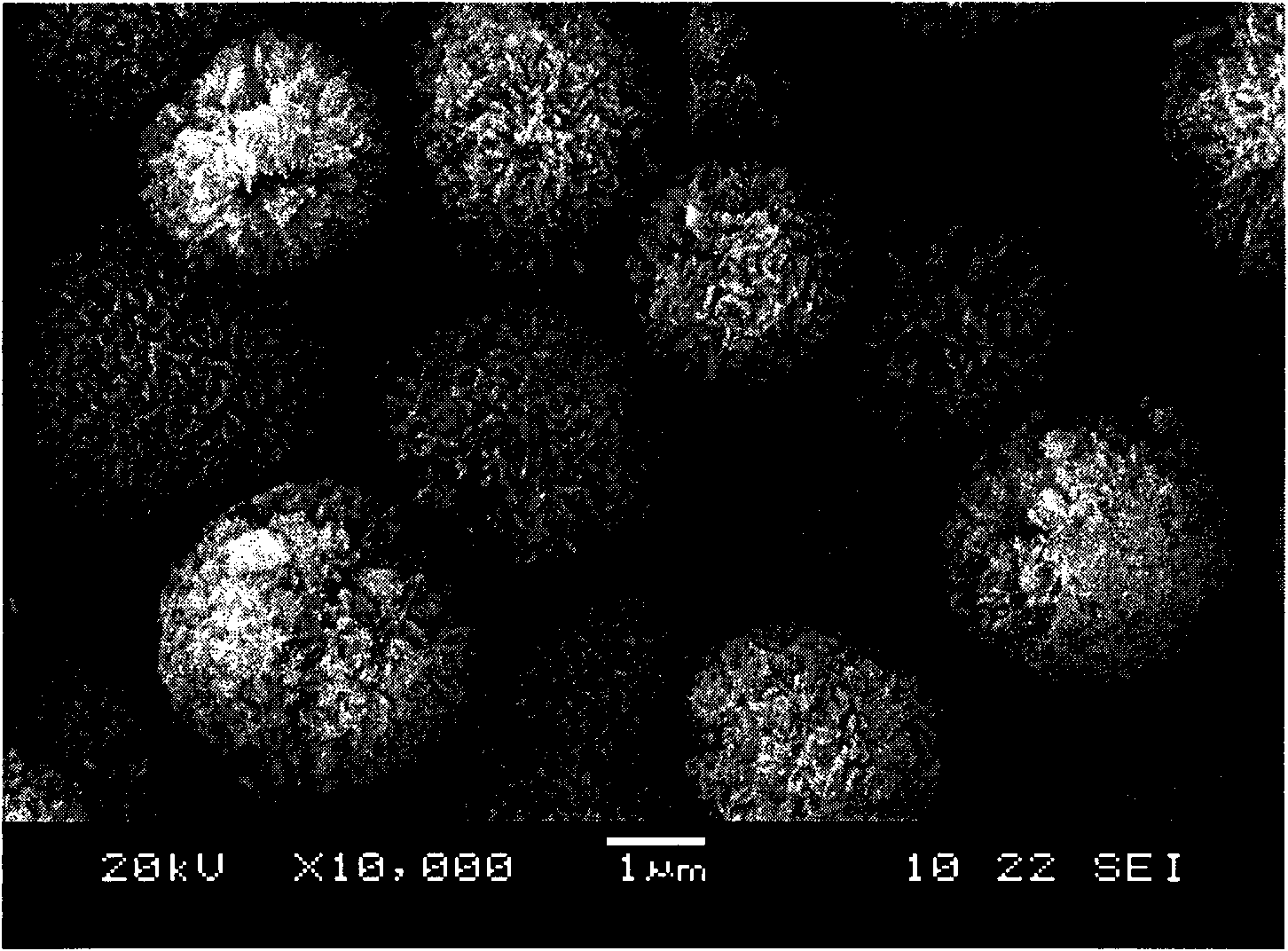

[0037] Embodiment one, the preparation method of spherical magnesium carbonate

[0038] (1) Dissolve industrial grade magnesium chloride in water, and obtain a solution with a concentration of 1.0mol / L after filtration; dissolve industrial grade sodium carbonate in water, and obtain a solution with a concentration of 1.2mol / L after filtration.

[0039] (2) Take 10 mL of each of the above two solutions and place them in a constant temperature water bath to keep the temperature at 30°C.

[0040] (3) Weigh 23.025g of sodium tartrate, dissolve it, transfer it to a 200mL volumetric flask, dilute to volume, and prepare a solution with a concentration of 0.50mol / L.

[0041] (4) get the sodium tartrate solution that 5mL step (3) configuration is placed in reaction vessel, stir with the speed of 500rpm with magnetic stirrer; After finishing the solution, the concentration of sodium tartrate in the reaction system was 0.1mmol / L. After the dropwise addition of the solution was complete...

Embodiment 2

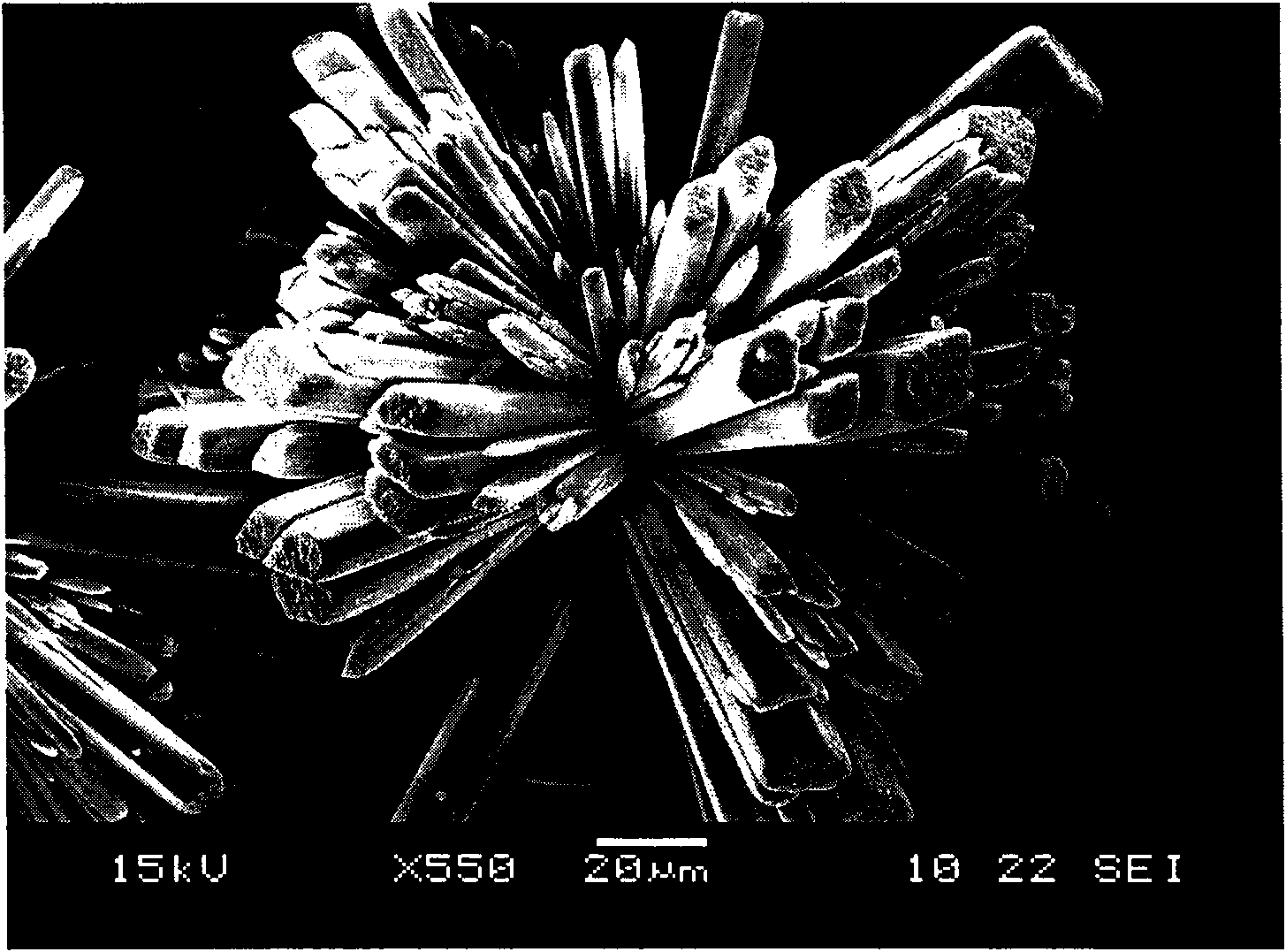

[0045] Embodiment two, the preparation method of radial magnesium carbonate

[0046] (1) Dissolve industrial grade magnesium chloride in water, and obtain a solution with a concentration of 1.0mol / L after filtration; dissolve industrial grade sodium carbonate in water, and obtain a solution with a concentration of 1.2mol / L after filtration.

[0047] (2) Take 10 mL of each of the above two solutions and place them in a constant temperature water bath to keep the temperature at 50°C.

[0048] (3) Weigh 23.025g of sodium tartrate, dissolve it, transfer it to a 200mL volumetric flask, dilute to volume, and prepare a solution with a concentration of 0.50mol / L.

[0049] (4) Get the sodium tartrate solution of 10mL configuration, be placed in reaction vessel, stir with the speed of 900rpm with magnetic stirrer; The concentration of sodium tartrate in the reaction system was 0.2mmol / L. After the dropwise addition was completed, the stirring was continued for 4 minutes, and then the ...

Embodiment 3

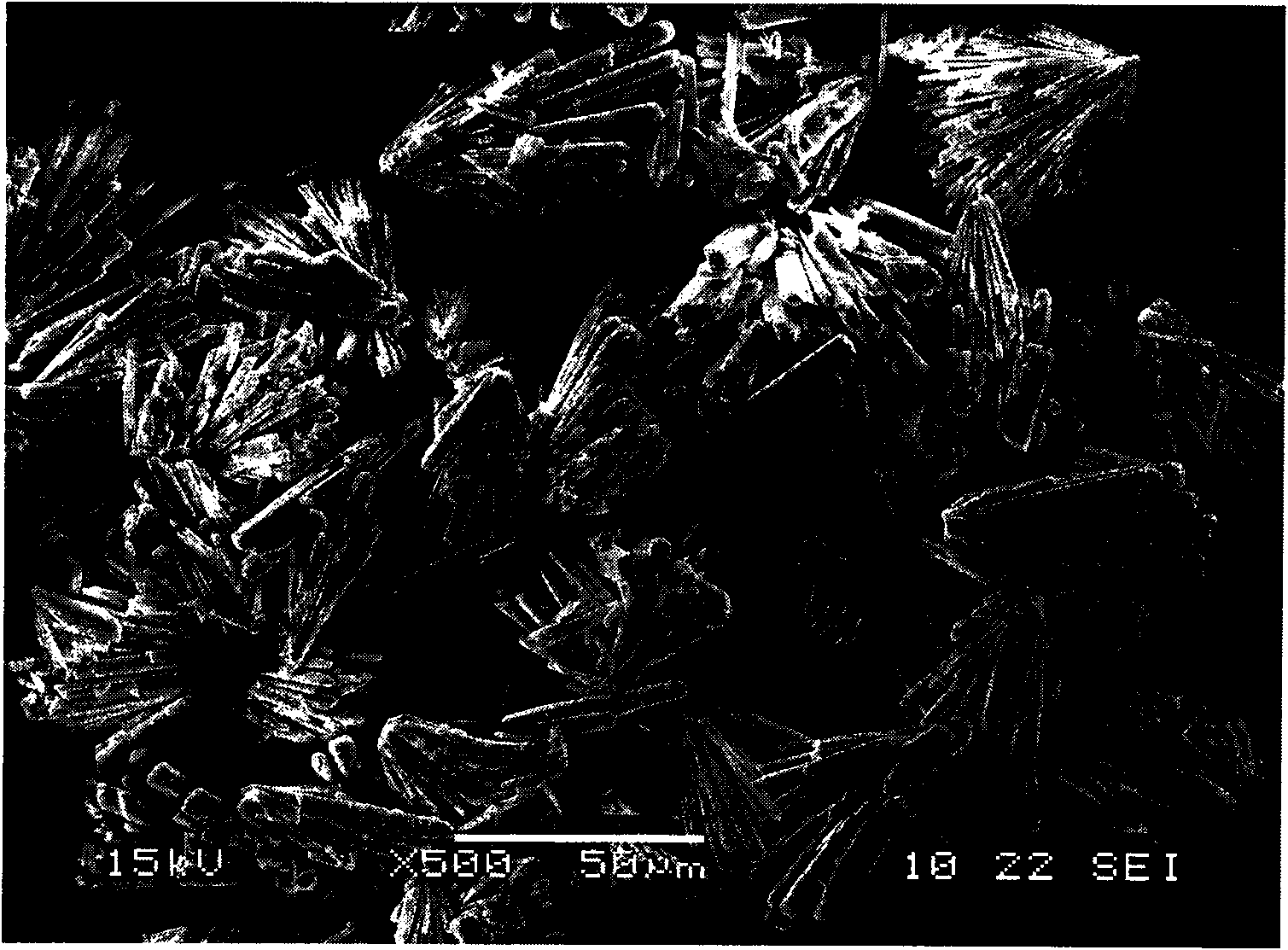

[0053] Embodiment three, the preparation method of radial magnesium carbonate

[0054] (1) Dissolve industrial grade magnesium chloride in water, and filter to obtain a solution with a concentration of 1.0mol / L; dissolve industrial grade sodium carbonate in water, and obtain a solution with a concentration of 1.2mol / L after filtration.

[0055] (2) Take 20 mL of each of the above two solutions and place them in a constant temperature water bath to keep the temperature at 25°C.

[0056] (3) Weigh 1.005g of polyacrylamide, dissolve it and transfer it to a 250mL volumetric flask, constant volume, and prepare a solution with a concentration of 4.02g / L.

[0057] (4) Take 5 mL of polyacrylamide solution and place it in a reaction vessel, stir it with a magnetic stirrer at a speed of 500 rpm; add the above-mentioned constant temperature magnesium chloride solution and sodium carbonate solution dropwise into the reaction vessel at the same time, after adding the solution, the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com