Water-borne polyurethane and preparation method thereof

A water-based polyurethane and hydrophilic technology, used in textiles and papermaking, can solve the problems of low modulus, difficult to adjust viscosity, low mechanical strength, etc., and achieve mild reactivity, easy control of preparation process, and good storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

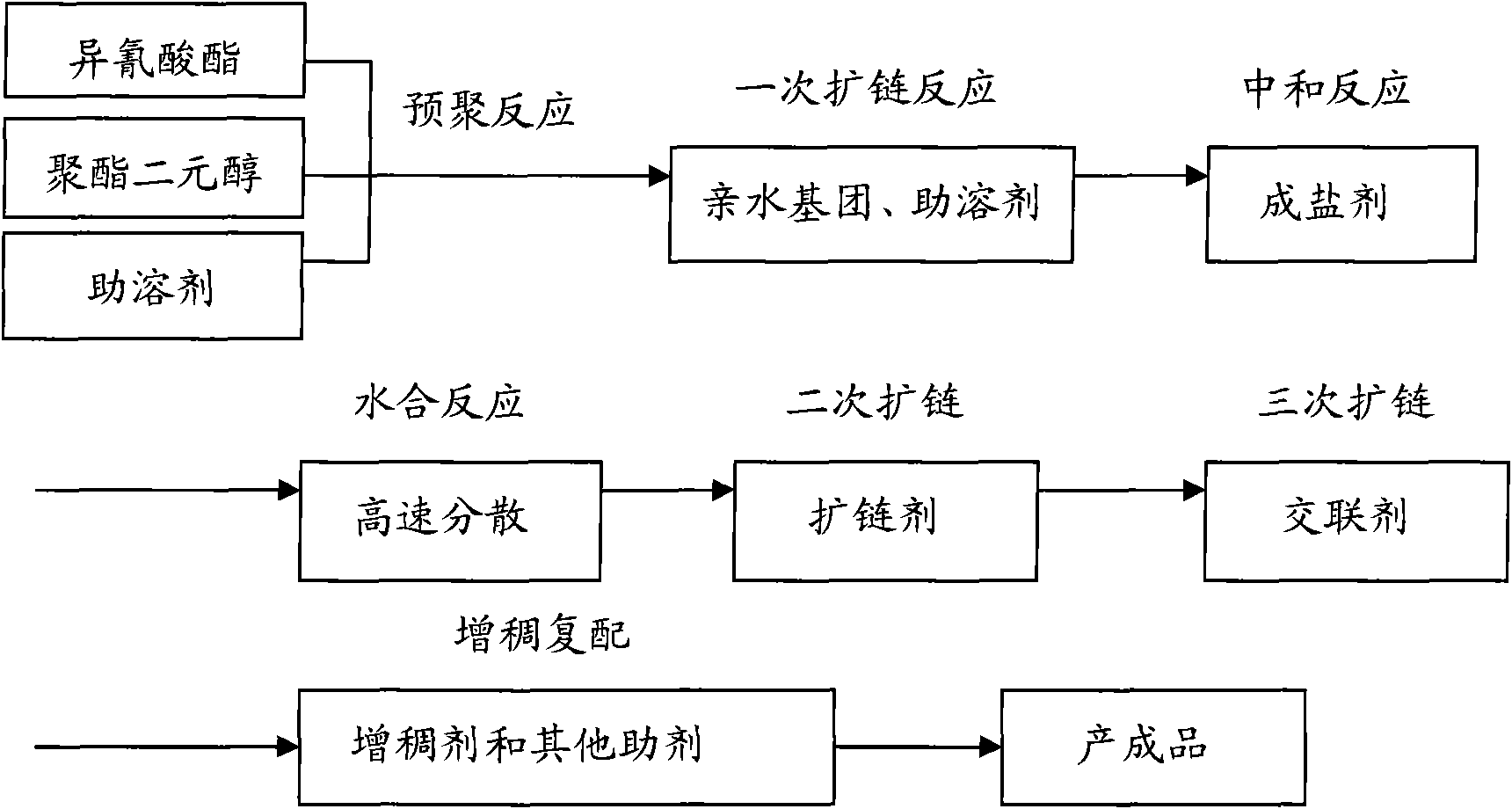

Method used

Image

Examples

Embodiment 1

[0046]Add 60g of isophorone diisocyanate (IPDI) to 150g of butanediol-adipic acid copolymer (PBA) (Mn=2000), and react at 70°C for 120 minutes; add 45g of acetone and control the temperature of the reaction tank At 50°C, 15g of dimethylolpropionic acid (DMPA) was added, and the reaction was continued for 180 minutes at 70°C; the temperature of the reaction tank was controlled at 50°C, and 12g of triethylamine (TEA) was added to neutralize for 30 minutes; 500g of deionized water was added to the neutralized and hydrophilic prepolymer for high-speed emulsification and dispersion, and 5.2g of triethylenetetramine (TETA) was added before the NCO value dropped to 1.5wt%. Continue at room temperature for 5 hours to obtain an aqueous polyurethane dispersion with a solid content of 32wt%; add a thickener and a leveling agent to the aqueous polyurethane dispersion to obtain a finished slurry for synthetic leather, and its viscosity is 3000cps / 20°C, pH 7-9. The tensile strength of the...

Embodiment 2

[0048] Add 55g isophorone diisocyanate (IPDI) to 145g butanediol-adipic acid copolymer (PBA) (Mn=2000), and react at 70°C for 120 minutes; add 40g acetone and control the temperature of the reaction tank At 50 °C, 14 g of dimethylolpropionic acid (DMPA) was added, and the reaction was continued for 180 minutes at 70 °C; the temperature of the reaction tank was controlled at 50 °C, and 11 g of triethylamine (TEA) was added for neutralization reaction for 30 minutes; 450g of deionized water was added to the neutralized and hydrophilic prepolymer for high-speed emulsification and dispersion, and 5.0g of triethylenetetramine (TETA) was added before the NCO value dropped to 1.5wt%. Continue at room temperature for 5 hours to obtain an aqueous polyurethane dispersion with a solid content of 33% by weight; add a thickener and a leveling agent to the aqueous polyurethane dispersion to obtain a finished slurry for synthetic leather, and its viscosity is 2500cps / 20°C, pH 7-9. The tens...

Embodiment 3

[0050] Add 60g isophorone diisocyanate (IPDI) to 150g butanediol-adipic acid copolymer (PBA) (Mn=2000), and react at 65°C for 125 minutes; add 45g of acetone and control the temperature of the reaction tank At 50°C, 15g of dimethylolpropionic acid (DMPA) was added, and the reaction was continued for 170 minutes at 65°C; the temperature of the reaction tank was controlled at 45°C, and 12g of triethylamine (TEA) was added to neutralize for 35 minutes; 500g of deionized water was added to the neutralized and hydrophilic prepolymer for high-speed emulsification and dispersion, and 5.2g of triethylenetetramine (TETA) was added before the NCO value dropped to 1.5wt%. At room temperature for 5.5 hours, a water-based polyurethane dispersion with a solid content of 32 wt% was obtained; adding a thickener and a leveling agent to the water-based polyurethane dispersion, the finished slurry for synthetic leather can be obtained, and its viscosity is 2700cps / 20°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com