High-strength high-toughness polypropylene regenerated particles and preparation method thereof

A technology of polypropylene and high toughness, which is applied in the field of recycling and utilization of waste plastics in the renewable resources industry. It can solve the problems of low added value of science and technology and poor quality of polypropylene recycled materials, so as to solve the problem of resource shortage, improve technological content, and solve environmental problems. problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

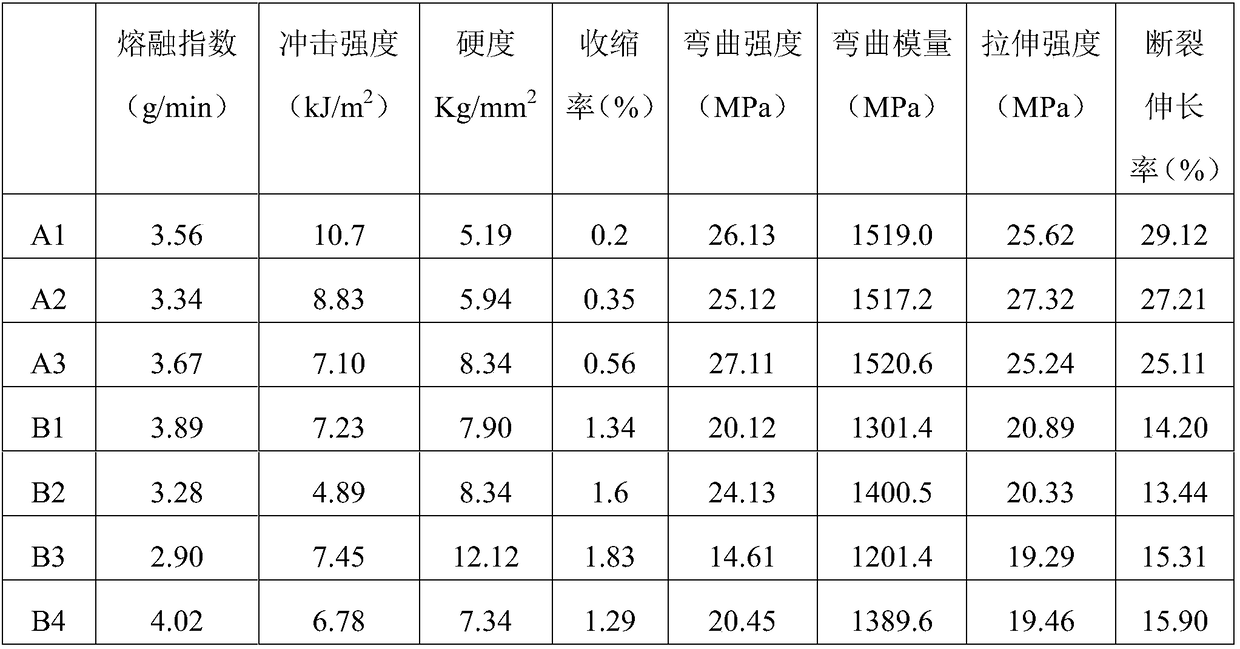

Examples

preparation example Construction

[0027] The preparation method of the high-strength and high-toughness polypropylene recycled particles of the present invention comprises the following steps:

[0028] Step 1, weighing raw materials by weight: waste polypropylene 40-60%, polyolefin resin 5-15%, elastomer 5-10%, inorganic rigid particles 10-20%, coupling agent 0.1-2%, reinforcement 5-20% of additives, 1-10% of compatibilizers, 0.1-1% of nucleating agents, and 0.5-1% of other additives;

[0029] Step 2: Activation of inorganic rigid particles: put the corresponding weight of inorganic rigid particles in step 1 into a 1000 rpm high-speed mixer, slowly add coupling agent for mixing and coating, control the temperature, stop mixing after 5 to 7 minutes, and obtain Activate inorganic rigid particles;

[0030] Step 3, blending the blend: first put the waste polypropylene resin, polyolefin resin, elastomer and activated inorganic rigid particles, reinforcing agent, compatibilizer into the high mixer and mix thoroughl...

Embodiment 1

[0033] A high-strength and high-toughness polypropylene regenerated granule, its components are: waste polypropylene 60%, polypropylene, high-density polyethylene, low-density polyethylene composition 6%; ethylene-octene copolymer (POE), ethylene - vinyl acetate copolymer (EVA) composition 8%; talcum powder 400 mesh, 800 mesh, 1250 mesh composition 19% (titanate or aluminate coupling agent 1%); magnesium sulfate whisker 3%; Maleic anhydride grafted polypropylene (PP-g-MAH), maleic anhydride grafted ethylene-octene copolymer (POE-g-MAH) composition 2%; stearic acid, calcium stearate, polyethylene wax 0.2 %, 0.5% of nucleating agent, 0.3% of titanium dioxide, to prepare regenerated particles A1.

Embodiment 2

[0035] A high-strength and high-toughness polypropylene regenerated granule, its components are: waste polypropylene 48%, polypropylene, high-density polyethylene, low-density polyethylene composition 6%; ethylene-octene copolymer (POE), thermoplastic Elastomer (TPE) composition 6%; modified talc powder, calcium carbonate composition 19% (titanate or aluminate coupling agent 1%); acrylonitrile-styrene copolymer (AS), glass fiber reinforced Polypropylene (GFPP) composition 17%; maleic anhydride grafted polypropylene (PP-g-MAH), maleic anhydride grafted ethylene-octene copolymer (POE-g-MAH) composition 2%; stearin Acid, calcium stearate, polyethylene wax 0.2%, nucleating agent 0.5%, titanium dioxide 0.3%, prepare masterbatch A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com