Treatment of phenol containing decanedioic acid waste water by extractive distillation

A technology of extractive distillation and phenolic wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems that cannot be popularized and applied, low distribution coefficient, and cannot be recycled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

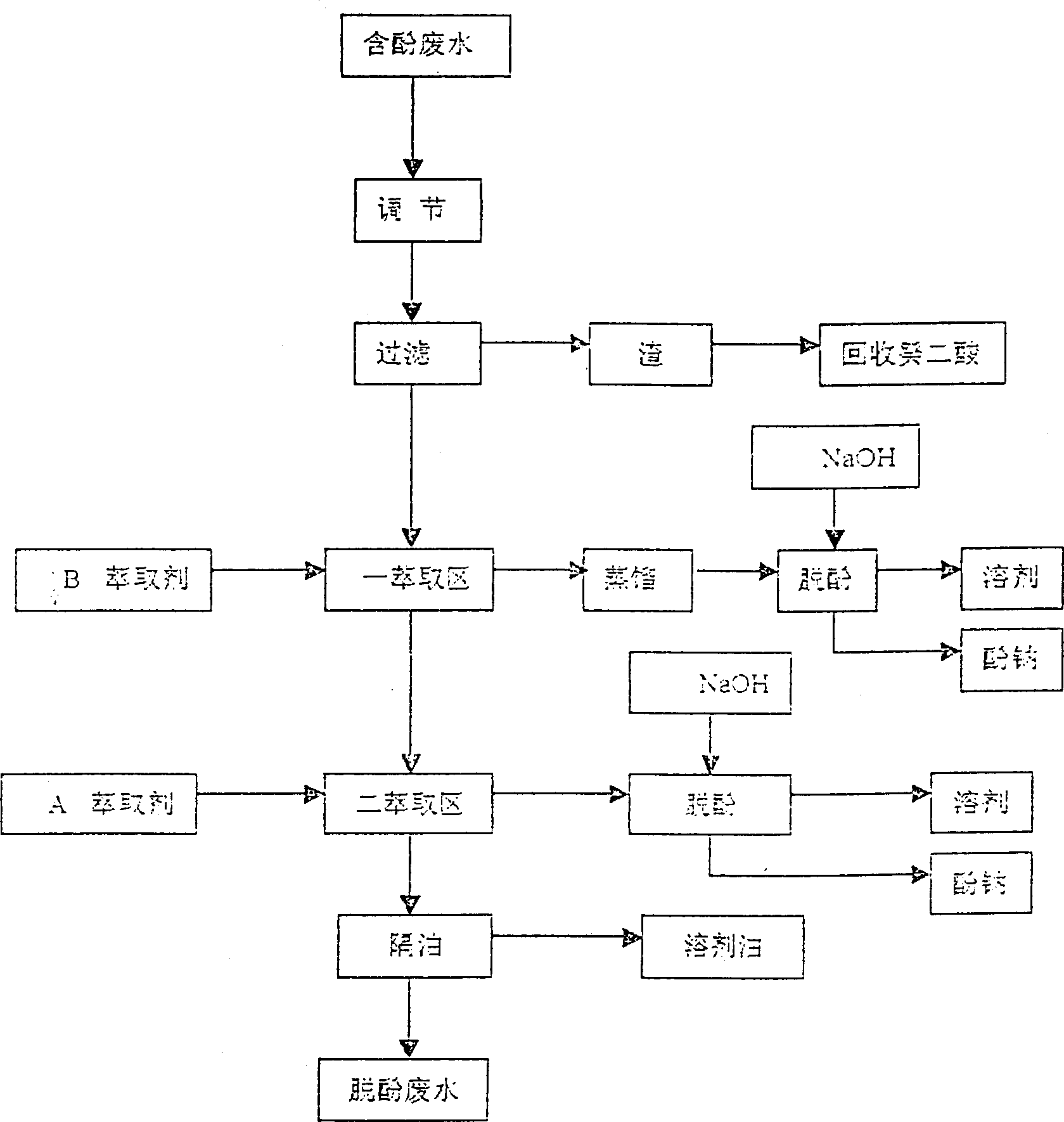

Image

Examples

Embodiment 1

[0015] Extractive distillation method of the present invention handles sebacic acid containing phenolic waste water and comprises the following steps:

[0016] 1. Adjustment. Due to the different discharge rules and water quality of the workshop wastewater, in order to ensure that the follow-up treatment process can operate under a relatively stable working condition to obtain a higher removal rate, the phenol-containing wastewater from the sebacic acid workshop first enters the regulating storage tank. Stay in the tank for a period of time to facilitate the balance of water quality and water quantity and prepare for subsequent treatment. Of course, this step can also be omitted if the water quality and water quantity of the wastewater are relatively balanced, or other forms of regulation have been obtained.

[0017] 2. Filter. The settled wastewater contains solid impurities. Under normal temperature and pressure of 0.2-0.35Mpa, it is filtered by a plate and frame filter pr...

Embodiment 2

[0022] The process of adjustment, filtration and oil separation is the same as in Example 1.

[0023] 3. Extraction. The filtered wastewater is pumped into the first extraction zone. In the first extraction zone, high-carbon alcohol (C8) is used as the extractant to countercurrently extract the phenol-containing wastewater. The volume ratio of the extractant to the phenol-containing wastewater is 1:40. The temperature is 30°C; the raffinate is sent to the second extraction zone, where the mixture of organic phosphate and kerosene is used as the extractant to extract countercurrently with the raffinate in the first extraction zone, and the extractant is mixed with the phenolic wastewater The volume ratio is 1:40, the temperature is 30° C., and the weight content of phosphate in the extractant is 20%. The raffinate is put into the grease trap, and discharged up to the standard after deoiling. The extracts from the two extraction zones enter the dephenolization process.

[002...

Embodiment 3

[0026] The process of adjustment, filtration and oil separation is the same as in Example 1.

[0027] 3. Extraction. The filtered wastewater is pumped into the first extraction zone. In the first extraction zone, high-carbon alcohol (C10) is used as the extractant to countercurrently extract the phenol-containing wastewater. The volume ratio of the extractant to the phenol-containing wastewater is 1:50. The temperature is 45°C; the raffinate is sent to the second extraction zone, and in the second extraction zone, a mixture of organic phosphate and kerosene is used as the extractant to countercurrently extract the raffinate in the first extraction zone, and the extractant is mixed with the phenol-containing wastewater The volume ratio is 1:50, the temperature is 45° C., and the weight content of phosphate in the extractant is 50%. The raffinate is put into the grease trap, and discharged up to the standard after deoiling. The extracts from the two extraction zones enter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com