Super high temperature resistant anti-corrosion coating and preparation method thereof

A technology for anti-corrosion coatings and high temperature resistance, applied in the direction of anti-corrosion coatings, coatings, etc., to solve the problem of coating compactness and ensure durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

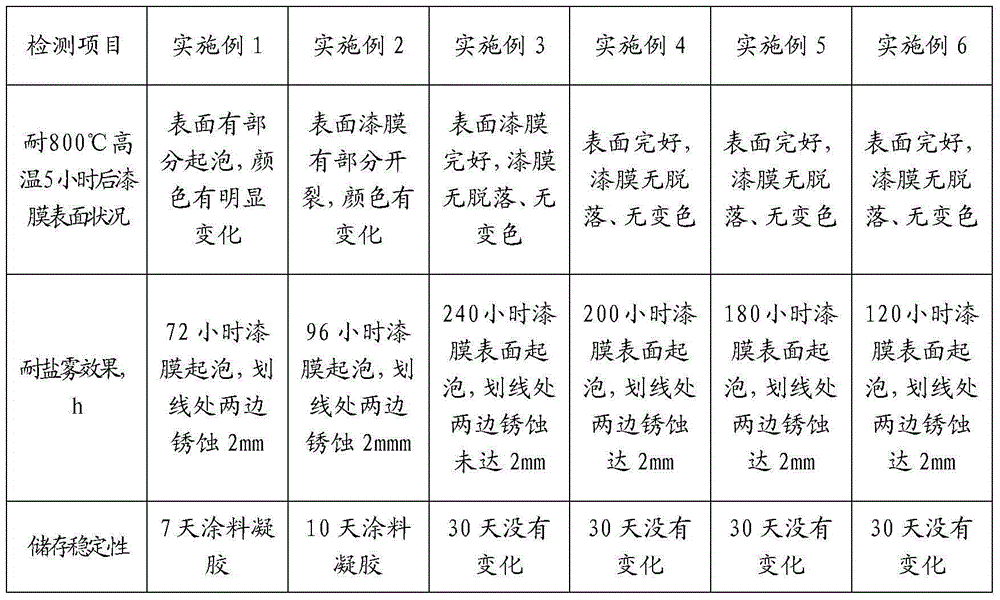

Examples

Embodiment Construction

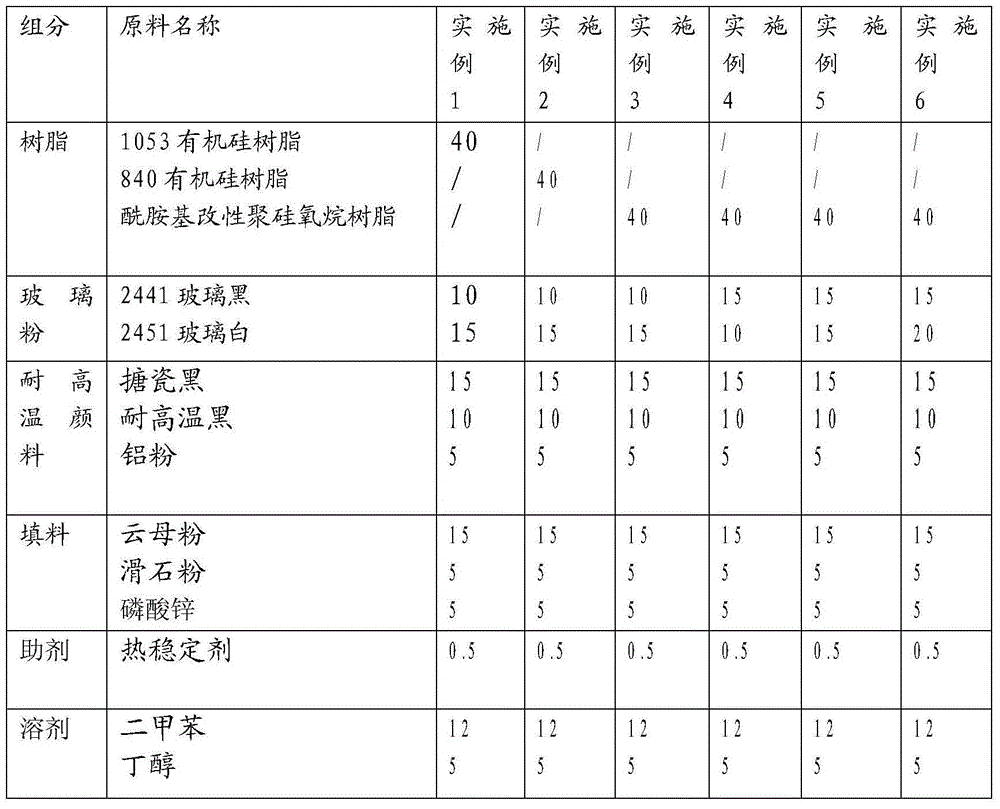

[0025] 1. Raw materials

[0026] Siloxane Monomer Industrial Products Wacker Chemie

[0027] 1053 Silicone resin industrial products Zhonghao Chenguang Chemical Co., Ltd.

[0028] 840 organic resin industrial products Dow Corning Chemical

[0029] Acrylamide Monomer Industrial Products Shanghai Chemical Reagent Co., Ltd.

[0030] Silicone coupling agent industrial products Nanjing Shuguang Chemical Co., Ltd.

[0031] Cetyl Ammonium Bromide Chemicals Jiangsu Jincheng Reagent Co., Ltd.

[0032] Heat Stabilizer Industrial Products Nantong Advan Chemical Co., Ltd.

[0033] 2441 Glass black industrial products Shanghai Tianguang Chemical Factory

[0034] 2451 Glass White Industrial Products Shanghai Tianguang Chemical Factory

[0035] Enamel Black Industrial Products Shanghai Tianguang Chemical Factory

[0036] Aluminum Powder Industrial Products Jinan Metal Pigment Co., Ltd.

[0037] Zinc Phosphate Industrial Products Shanghai Hengzhan Chemical Co., Ltd.

[0038] Mica Pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com