Low-water absorption biological nylon material PA610T and preparation method thereof

A technology of low water absorption and water absorption, applied in the field of low water absorption biological PA610T nylon material and its preparation, can solve the problems of reducing the multiphase coexistence and compatibility of nylon water absorption, and achieve low equipment cost, simple reaction steps, and high performance. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

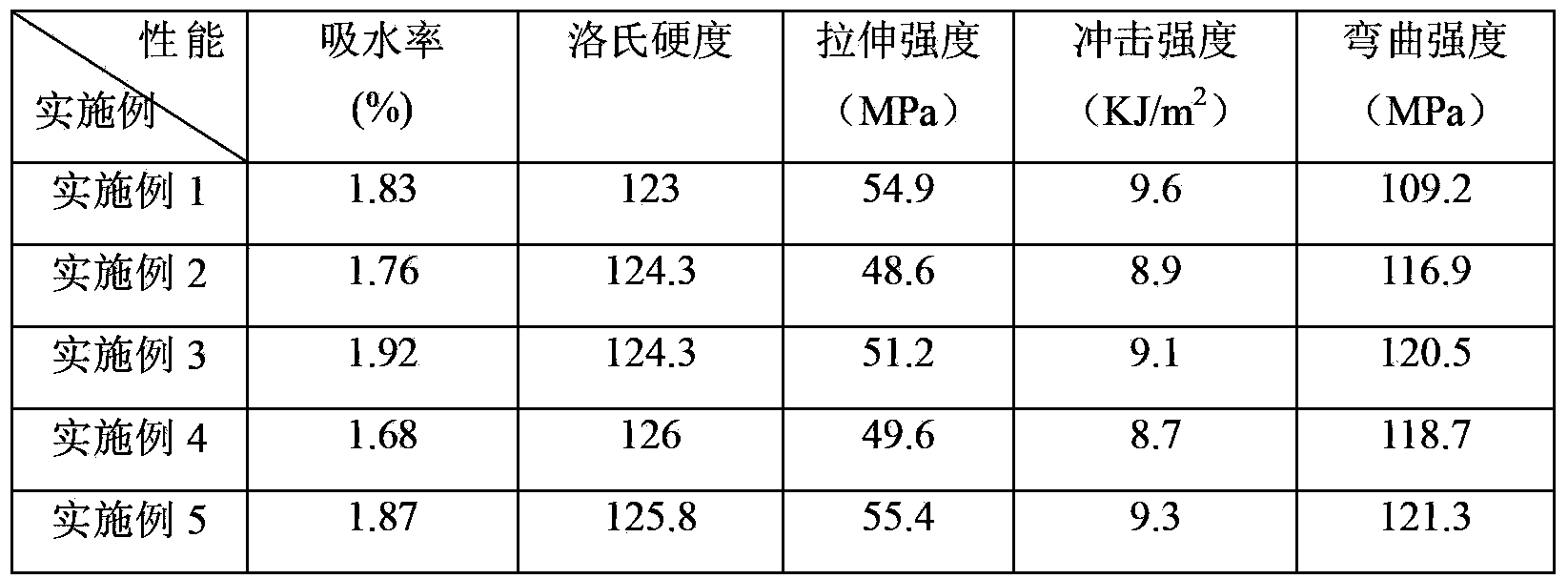

Examples

Embodiment 1

[0039] Weigh 1694.526g of terephthalic acid, 1982.05g of sebacic acid, 2266.095g of hexamethylenediamine, 1.2896g of sodium hypophosphite, mix well and pour it into a 25L polymerization reactor, inject 3.96kg of deionized water and The nucleating agent barium sulfate 8.16865g is placed in the reactor, the stirring device is turned on, the stirring speed is 60r / min, the air reserved in the reactor is replaced with nitrogen for at least three times, and 0.02MPa nitrogen is reserved as a protective gas.

[0040] The reactor is heated by circulating heat transfer oil at a rate of 15°C per minute, and the temperature rises to 300°C (there is a process of maintaining pressure in this process, and the pressure is released after the pressure is maintained. When the temperature rises to 300°C, the pressure is maintained. The pressure value is 3.0MPa, and the boosting time is about 45min) (the boosting time refers to the stage from the end of the heat preservation to the pressure holding...

Embodiment 2

[0042] Weigh 1711.139g of isophthalic acid, 1961.825g of sebacic acid, 2277.716g of hexamethylenediamine, and 6.5745g of magnesium phosphate in proportion, mix well and pour it into a 25L polymerization reactor, inject 4.68kg of deionized water and nucleate Put 4.7042g of calcium carbonate in the reaction kettle, turn on the stirring device, the stirring speed is 60r / min, fill in helium to vacuumize, repeat 3 times, get rid of the air reserved in the kettle, and reserve 0.05MPa helium as protective gas.

[0043]The reactor is heated by circulating heat transfer oil at a rate of 12°C per minute, and the temperature rises to 300°C. When the temperature of the reactor is 120°C, the inside of the reactor is kept warm for 1.5 hours. After the heat preservation is completed, the reactor is heated. When the temperature rises, the pressure rises accordingly. After the pressure rise time is about 28 minutes, when the pressure is 2.25MPa, the pressure of the reactor is realized by relea...

Embodiment 3

[0045] Weigh 1882.2529g of phthalic acid, 2158.0075g of sebacic acid, 2510.60084g of hexamethylenediamine, and 2.0414g of potassium hypophosphite in proportion, mix them uniformly and pour them into the polymerization reactor, inject 5.22kg of deionized water and Put 3.0042g of nuclear agent silicon dioxide in the reaction kettle, turn on the stirring device, the stirring speed is 60r / min, fill in argon to vacuumize, repeat 3 times, remove the air reserved in the kettle, and reserve 0.03MPa argon gas as a protective gas.

[0046] The reactor is heated by circulating heat transfer oil at a rate of 13°C per minute, and the temperature rises to 300°C. When the temperature of the reactor is 130°C, the inside of the reactor is kept warm for 1.5 hours. When the temperature rises, the pressure rises accordingly. After the pressure rise time is about 33 minutes, when the pressure is 2.4MPa, the pressure of the reactor is maintained by releasing the water vapor generated by the system ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com