Method for preparing graphene by inorganic membrane reactor

A technology of inorganic membrane and reactor, applied in the field of graphene prepared by inorganic membrane reactor, can solve the problems of unsatisfactory graphene structure, high production cost, harsh experimental conditions, etc., and achieve easy mass production, simple production process, high The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

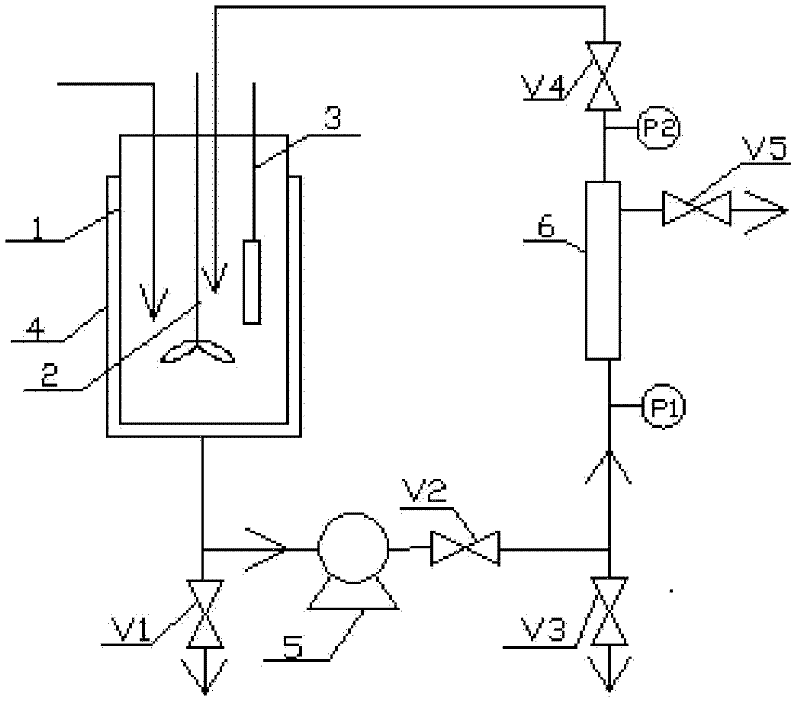

[0027] as attached figure 1 As shown, add 2.5kg mass concentration successively in reaction kettle 1 and be the concentrated sulfuric acid of 98%, 100g graphite powder, 100g potassium permanganate and stir evenly, pass circulating cooling water in the jacket of reaction kettle, make reaction kettle in Cool to 0°C in an ice-water bath, and cool for 0.5h. The reaction temperature was controlled at 70° C. by a water bath, and the mixture was continuously stirred and reacted for 1 h under the condition of a constant temperature water bath at 70° C. to obtain a graphite oxide suspension. Add 200g mass concentration of 20% hydrogen peroxide aqueous solution to wash the graphite oxide suspension. The material is transported to the membrane module 6 through the circulation pump 5 for membrane filtration and separation. After washing and concentration, graphite oxide with a solid content of 25% is obtained in the reaction kettle. suspension. Raise the temperature to 85°C, add 50g of ...

Embodiment 2

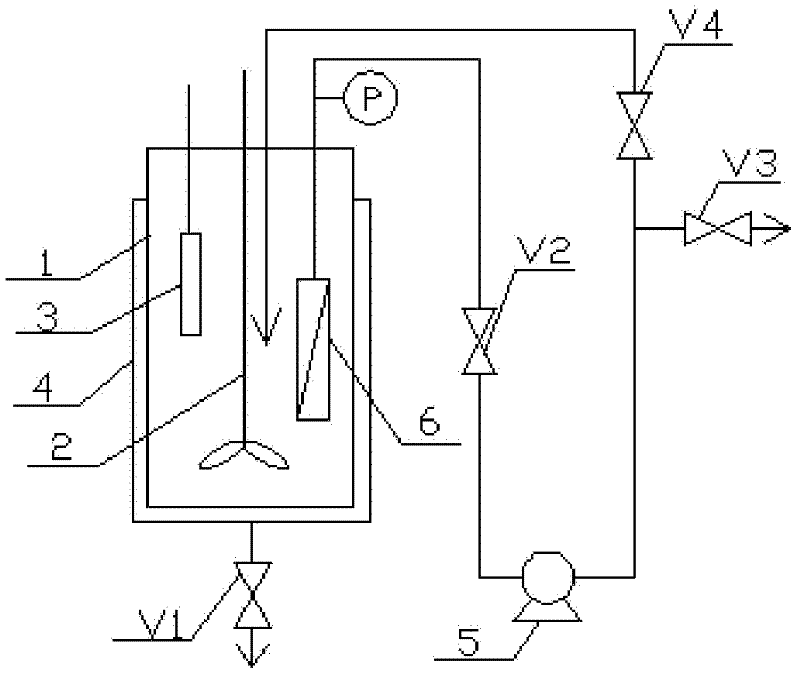

[0029] as attached figure 2Shown, add 5kg mass concentration successively in reaction kettle 1 and be the concentrated nitric acid of 95%, 100g graphite powder, 400g potassium perchlorate and stir evenly, pass circulating cooling water in the jacket of reaction kettle, make the reaction kettle in the ice-water bath Cool to 2°C in medium temperature, cold treatment for 1h. The reaction temperature was controlled at 90° C. by a water bath, stirring was continued and reacted for 4 hours under the condition of a constant temperature water bath at 90° C. to obtain a graphite oxide suspension. Adding 1 kg of mass concentration of 30% hydrogen peroxide solution to wash the graphite oxide suspension, start the circulation pump 5, and use the membrane module 6 to perform membrane filtration on the material in the reactor. After washing and concentration, the reactor with a solid content of 30% graphite oxide suspension. Raise the temperature to 100°C, add 600g of hydrazine hydrate t...

Embodiment 3

[0031] as attached figure 1 As shown, add 8.5kg of perchloric acid, 100g of graphite powder, 250g of sodium perchlorate, 250g of potassium permanganate, and 250g of potassium perchlorate successively in reactor 1 with a mass concentration of 97% and stir evenly. Cooling water was circulated through the jacket, so that the reactor was cooled to 5°C in an ice-water bath, and cold treated for 1.5 hours. The reaction temperature was controlled at 130° C. by a water bath, and the mixture was continuously stirred and reacted for 6 h under the condition of a constant temperature water bath at 110° C. to obtain a graphite oxide suspension. Add 1.8 kg of mass concentration of 40% hydrogen peroxide aqueous solution to wash the graphite oxide suspension, and the material is transported to the membrane module 6 through the circulation pump 5 for membrane filtration. After washing and concentration, the graphite oxide suspension with a solid content of 35% is obtained in the reactor. grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com