Tooling for processing lamp spherical holder

A spherical seat and lamp technology, applied in the direction of expanding the mandrel, can solve the problems of unstable fixation, affecting processing accuracy, affecting production efficiency, etc., and achieves the effect of convenient and fast clamping, easy operation, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

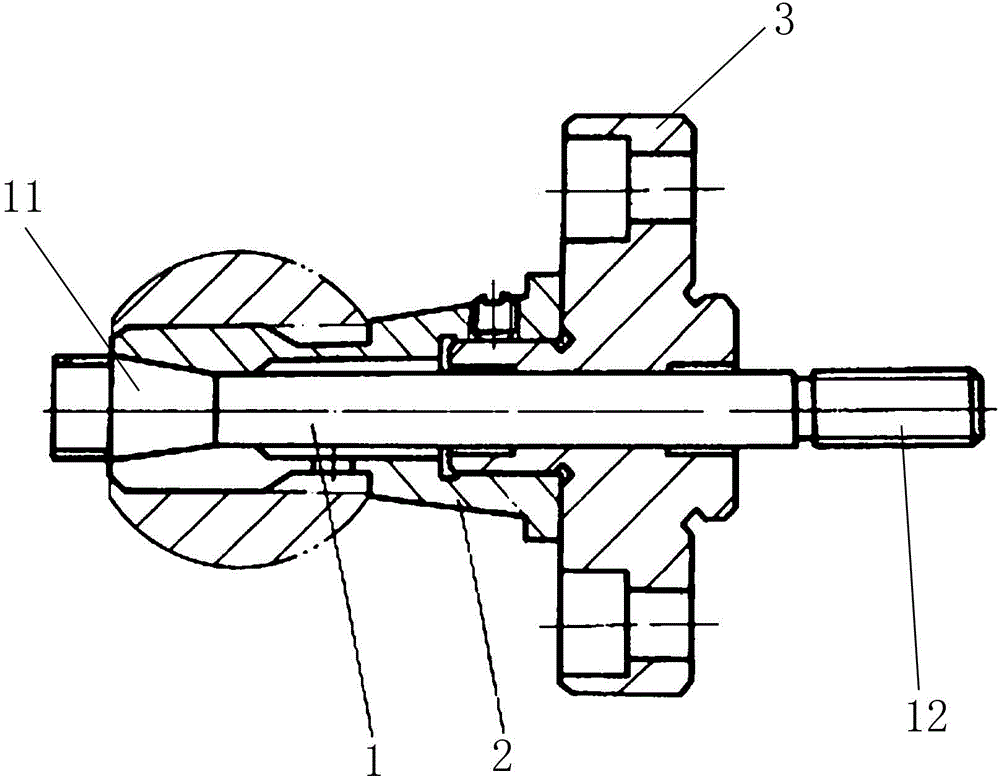

[0013] The reference signs in the drawings of the description include: a pull rod 1 , an elastic mandrel 2 , a base 3 , a pressure head 11 , and a threaded part 12 .

[0014] The embodiment is basically as figure 1 Shown: The tooling for processing the spherical seat of lamps includes a base 3, six mounting holes are provided on the circumference of the base, which facilitates the installation and disassembly between the base and the spindle of the machine tool, and also includes a pull rod 1, an elastic mandrel 2, and a pressure head 11, the base It is hollow, and the base is detachably connected to the main shaft of the machine tool. The right end of the base is provided with a positioning boss, the left end of the base is provided with a mounting boss, the center of the base is provided with a slideway, and the elastic mandrel includes a number of The fins and the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com